A common issue arising from incorrectly specified or designed pipework is low pressure, often caused by the pipe being oversized. If the specified pipe is too large, the supply pressure cannot be sustained, causing flow rates to be reduced.

However, undersizing can also result in a lower flow rate because the pipework restricts the amount of water or gas that can be supplied. Therefore, balancing the volume required with maintaining pressure is vital.

In residential buildings with low flow rates, occupants will find that sinks and baths take longer to fill, and showers will not be able to supply adequate levels of water.

In addition to the implications for the user experience, there is also a safety issue to consider. A low flow rate of cold water to mixer taps or showers that do not have thermostatic protection could cause serious scalding injuries as a result of the sudden rise in water temperature.

Similarly, for gas pipework, the BS 6891 standard states that for mains gas, domestic pipework should be a maximum pressure drop of 1mbar during periods of highest demand. This is because if the pressure or volume of gas to the burner drops too low it can cause incomplete combustion, which can produce potentially lethal levels of carbon monoxide.

Furthermore, ensuring the correct system pressure and flow velocity is also crucial to protecting the supply of potable water within the building. A pipework design that allows water to stagnate will provide an ideal environment for bacteria, such as legionella pneumophila, to grow.

Low water pressure also increases the risk of contamination from backflow where fluids are unintentionally drawn into drinking-water systems from other pipework or outlets.

The physical design and layout of the pipework also has an effect on the system. Long pipe runs can cause significant pressure losses from the point it enters the property. The pipe itself, fittings and route of the pipework will all contribute to the friction in the system and reduce the flow.

As such, minimising the number of joints, bends and elbows in the pipework also helps reduce the friction in the system and maintain pressure.

To protect the health of building occupants, it is important pipework design does not cause excessive changes in the temperature of the water. Legionella bacteria breed most effectively between 25 and 45°C and, although hot water may be heated and stored above the recommended 50°C, the temperature at the outlets could be lower at the far ends of the system. Similarly, the temperature of cold water supplies can rise as it travels through the building – especially if routed close to sources of heat.

This can cause the temperature to enter the range where bacteria can grow rapidly. For this reason, the correct levels of insulation will not only improve the energy efficiency of the building, but also protect the quality of the water supply.

In addition to optimising the layout of the system, the specification of the components can make a significant difference. With each joint potentially adding to the resistance in the system, the correct product choice can help maintain the flow and pressure.

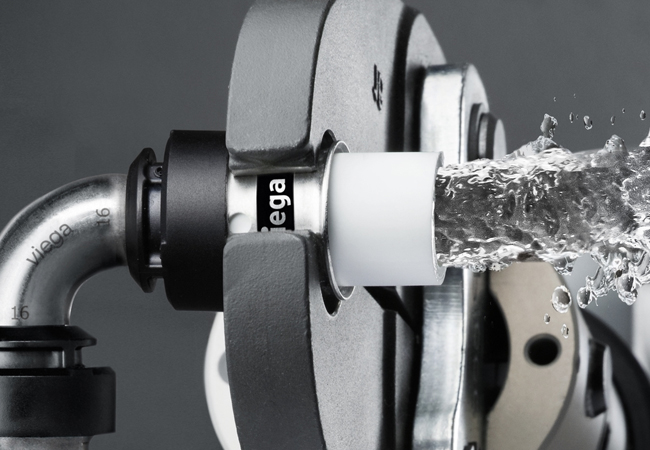

Press connection systems provide a quick, clean and reliable solution but it is important to consider the design of the fitting. Some lower quality systems will reduce the internal dimensions of the pipe when pressed and this ‘throttling’ action results in pressure loss and lowered flow rates. This is particularly true for large buildings where small reductions from each of the thousands of connections have a cumulative impact on the performance.

The careful engineering that goes into quality press connection systems means that products are available that feature flow optimised internal structures to further reduce the amount of resistance in the system. Fittings that have very low resistance coefficients (zeta values) can reduce pressure loss by as much as 80% compared to standard designs. For example, a standard design connector with a zeta value of 13.9 will result in the pressure loss of 95mbar, while a flow optimised alternative such as Viega’s Smartpress, with a zeta value as low as 2.7 will result in a pressure loss of only 18mbar across the system.

When designing pipework, it is vital it meets the requirements of the building and will function as intended once in operation. Although not always fully recognised, there are a number of design and specification factors that can affect performance of pipework systems and even impact the safety of building occupants.

Viega offers a CIBSE-accredited CPD course on pipework design for the supply of potable water. To find out more about the CPD and Viega’s range of press connection solutions visit www.viega.co.uk