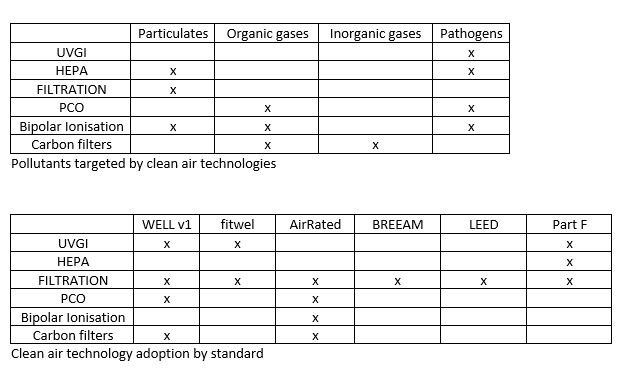

In this article, we will take a look at how healthy building standards define good indoor air quality and what solutions you can deploy that they recommend for improving indoor air quality.

Established environmental building standards like LEED and BREEAM have been around since the early 90’s, but during the coronavirus pandemic, sustainability took a back seat and the attention rapidly switched to healthy building standards.

Many of these standards had been around for several years pre-pandemic but only recently caught the attention of built environment professionals. While some of the environmental building standards incorporate indoor air quality into their programmes, as they cover so many other aspects of a building, it tends to be light touch.

The WELL standard was the first of the major wellbeing in buildings standards. Initial adoption was slow due to the associated costs with meeting the standard and achieving certification. The holistic approach to building wellness means that all aspects of the building have to be enhanced, often at significant cost over a standard spec office. The pandemic rapidly increased interest in the existing standard, and a simpler & cheaper standard was introduced that covered health and safety specifically, adoption of the simpler cetification rapidly increased the square footage of buildings with a WELL badge.

Fitwel came along in 2017 as a direct competitor and grew rapidly due to more accessible pricing and less onerous testing methodology. It focusses less on the building than WELL and focuses more on location, transport and amenities.

RESET has been established since 2014 and although their building certification has seen limited project uptake globally, their IAQ sensor certification, and IAQ limits have experienced adoption globally. RESET is primarily a data standard for IAQ, it does not advise on how to meet any of its IAQ parameter limits.

AirRated has seen rapid growth since its conception in 2018 due to its focus purely on air quality at a time when air quality was front of mind for building owners and designers. The combined approach of assessing indoor air quality in existing buildings via monitoring combined with the consultative Design and Operation (D&O) certification for buildings at design stage is unique.

As part of the D&O certification, AirRated guide building services design engineers through the specification process with the aim of achieving high quality indoor environments by influencing HVAC design.

The BREEAM credit Hea02 covers indoor air quality. The primarily focus is on source control from building products. Optimising the location of outdoor air systems intakes to avoid pollution or unintended re-circulation is one of the other credits available.

LEED historically had few sections covering indoor air quality, but a number of new pilot credits concern indoor air quality. Overall ventilation rates are specified, but the rest of the standard focusses on post-occupancy testing for a range of pollutants.

UVGI

Ultraviolet germicidal irradiation has been used for decades to control microbial and mould growth on cooling coils, this remains the best application for the technology, as it offers a payback in both increased coil efficiency and reduced maintenance. During the pandemic, an ability to infect pathogens in a moving airstream has seen its endorsement.

- UVGI is given credit in WELL v1 in the advanced air purification section as an air sanitisation solution for densely occupied spaces. And in WELL v2 for microbe and mould control on cooling coils.

- The Fitwel Enhanced Indoor Air Quality Policy was launched as a covid response. In this document, UVGI in the HVAC system, or upper room UVC is recommended.

- Part F of the UK building regulations recommends UVGI for centrally recirculating HVAC systems in offices.

Particle filtration

Particle filters for AHUs are typically selected on a rule of thumb basis, with the primary intention of simply keeping the HVAC system clean. Most of the healthy building standards set limits for particulate levels that should be verified post-completion.

- In the latest version of WELL, filters with a5 removal of ≥90% are recommended for re-circulating systems.

- Extra credits for filtration are awarded for deploying filtration grades ranging from ePM2.5 80% to ePM2.5-95% according to the outdoor particulate pollution concentrations.

- AirRated guide designers through the process of selecting appropriate filtration grades according to the desired internal pollutant concentrations in line with BS EN 16798-3:2017, with filter efficiencies selected based on outdoor air concentrations and the height of the buildings air intakes.

- BREEAM recommend that filtration is selected according to BS EN 16798-3:2017 achieving SUP category 2.

- LEED require equivalent filtration media class of ePM1 50% or higher, as defined by ISO 16890-2016

HEPA

HEPA (High Efficiency Particle Air) filters are classified according to EN 1822, ISO 16890 does not cover filter efficiencies at the HEPA level. HEPA filters are typically used in medical, pharmaceutical and cleanroom industries

- Part F does not specify general filtration grades, it only gives guidance for “typical situations”. It suggests that Expert advice may also be able to provide additional guidance on the suitability of other technologies to minimise the intake of external air pollutants. HEPA (to EN 1822) is a requirement for recirculating ventilation systems in offices only. While this could be designed in to a new HVAC system, it is unlikely to be a viable solution for existing plant, as the increase in pressure drop over a conventional filter is significant.

Photocatalytic oxidation (PCO)

Photocatalytic oxidation systems typically use a UV lamp shining on a honeycomb catalyst material. This creates localised Reactive oxygen species that react with organic compounds to break them down. PCO systems are positioned within the AHU or in the supply air ductwork.

- In the AirRated D&O certification, when fitted to the AHU, PCO is recognised as a solution for reducing inorganic gas concentrations in the outdoor air supply and for improving HVAC hygiene.

- PCO is given credit in WELL v1 in the advanced air purification section as an air sanitisation solution for densely occupied spaces.

Bipolar ionisation

Bipolar ionisation electrically charges the air being delivered by the HVAC systems by either adding or removing an electron. This charge is given over to particulate pollution in the air. Positive and negatively charged particles are attracted to each other through a process called agglomeration. Eventually the particles are large enough to fall out of the breathing zone, or they are large enough to be captured by coarse grade filters. The electrically charged ions also react with organic gasses, breaking them down.

- Bipolar ionisation (BPI) is a solution acknowledged by the AirRated D&O certification as a method for reducing levels of organic gasses (VOCs) and particulate matter. If BPI is fitted in the AHU, the reduction in modelled pollutant levels is primarily applied to the outdoor air supply concentrations being brought into the building.

- If BPI is fitted to the fan coil units serving the occupied space, reductions in VOCs generated by the occupants, building materials and furniture are also acknowledged.

Carbon filters

Common inorganic pollutants are Ozone, Nitrogen Dioxide and Sulpur dioxide, these are all gases, and will not be removed by conventional particle filtration, to remove a gas, you need a molecular filter, a common example is an activated carbon filter.

- Carbon filters are given credit in WELL v1 in the advanced air purification section for HVAC systems that re-circulate air

- AirRated give credit to carbon filtration for reducing organic gasses in outside air and also for inorganic gasses (like NO2)