A thermal wheel in an air handling unit

Ever since scientists discovered that Covid-19 is an airborne virus, ventilation systems have been a focus of attention during the pandemic. The European Centre for Disease Prevention and Control (ECDC) has stated that the risk of human infection with SARS-CoV-2 caused by air distributed through the ducts of HVAC systems is rated very low,1 but it is prudent to review existing or future installations.

CIBSE has produced excellent guidance2 that identifies the three principal types of air handling units (AHU) – run-around coils (RAC), plate heat exchangers and thermal wheels – and the associated risks of recirculating contaminated air. Section 4.2.2.1 of the CIBSE guide states that RAC and plate heat exchange units keep the supply air and the extract airstreams separate. While this is true for RAC, there is always a risk of slight leakage from plate heat exchangers. A plate can comply with EN3083 with an internal leakage of up to 3%, though this is reduced to 0.5% for a Eurovent-certified unit.

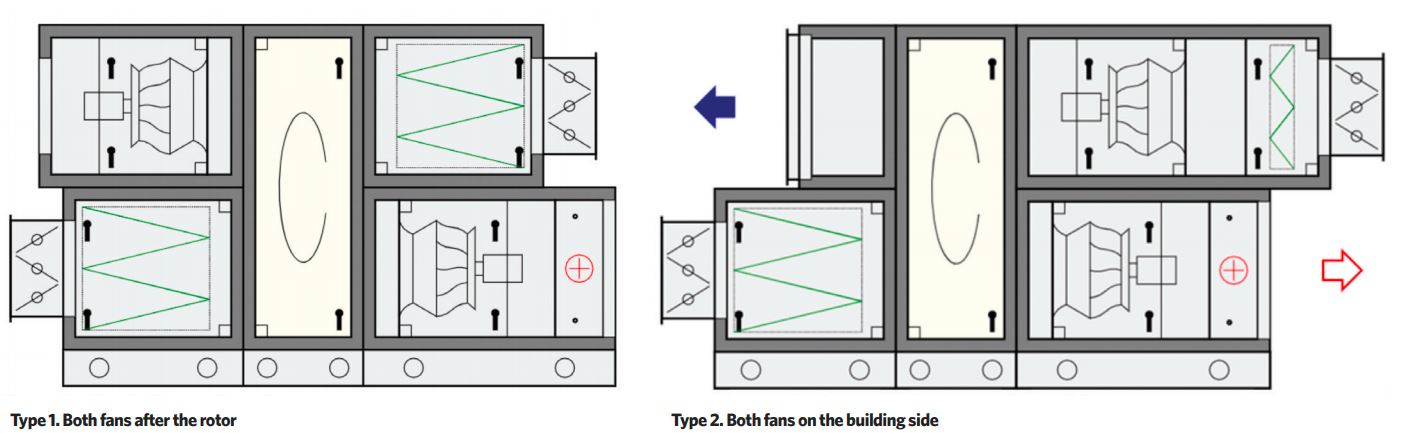

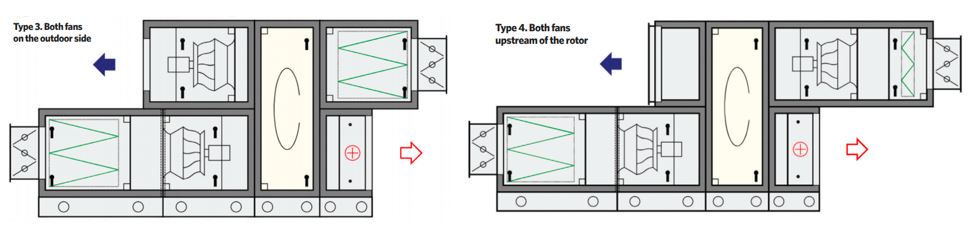

The supply and extract airstreams of an AHU with a thermal wheel can never be sealed completely and some degree of leakage between airstreams is inevitable. This leakage occurs even when the rotor is switched off, so there is no benefit in deactivating the rotor if the fans are kept running for ventilation. The amount of leakage is dependent on: the location of the fans relative to the rotor; if the rotor is fitted with a purge sector; and the static pressures in the ductwork.

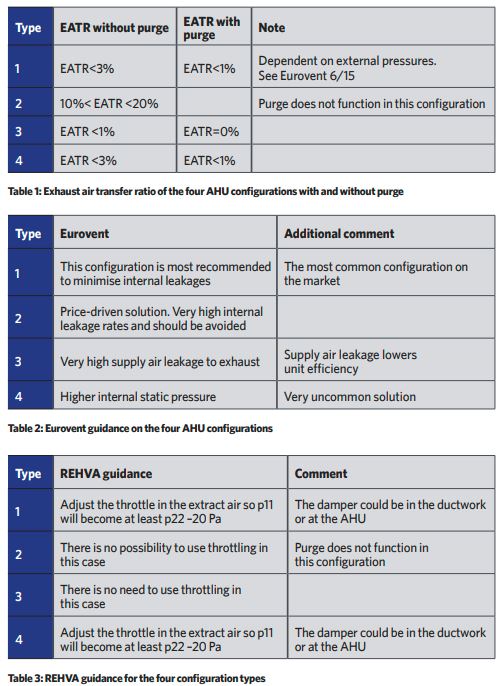

REHVA’s Covid-19 advice says that ‘the purge sector is a device that can practically eliminate the leakage resulting from the rotation of wheel [carry-over]. Its location and setting [angle] must be arranged according to manufacturer guidance depending on the configuration of fans and pressure relations’.4 There is however, a standard for the amount of exhaust air that is transferred into the supply airstream. EN 16798-35 defines the exhaust air transfer ratio (EATR) as the ‘level of carry-over of extract air to the supply air’. Reducing the EATR reduces the amount of contaminated material that can be recirculated.

Eurovent has produced a guide to air leakage in AHUs.6 It identifies the four possible fan configurations of AHUs with thermal wheels and gives the typical EATR with and without a purge sector for given external and internal pressure regimes. Table 1 gives the EATR based on normal Part L-compliant external static pressures. Eurovent also gives guidance for each individual configuration (Table 2) and I have added an additional comment if applicable. As can be seen in Table 2, the Eurovent-recommended configuration Type 1 – the most common – has an EATR equivalent to, or lower than, an EN308-compliant plate heat exchanger (EATR < 3%).

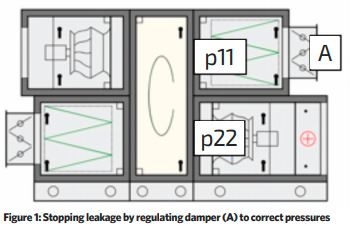

There is an additional measure than can lower the EATR even further. REHVA’s document4 Limiting internal air leakages across the rotary heat exchanger states that the ‘next step to eliminate a leakage is to set the correct relation between pressures p22 and p11 [see Figure 1]’. This pressure can be achieved by regulating the exhaust damper (A) correctly positioned on the system side of the exhaust airstream (Figure 1). If the correct pressure is achieved for the recommended configuration, the EATR can be considered virtually zero

In conclusion, AHUs with rotors can have an EATR equivalent to, or lower than, plate heat exchangers if the fans are in the recommended configuration, and the unit is fitted with a purge sector. Many existing installations could be put back into operation safely, but a competent engineer should ensure the recommended configuration and presence of a purge sector. For additional security, add pressure control.

Specifying AHUs with all of these in place will ensure new installations reduce the already very low potential risk to a minimum, while delivering the highest efficiency and lowest life-cycle costs.

■ DAVID BLACK is global product marketing manager – modular AHU at FläktGroup

References:

- Heating, ventilation and air conditioning systems in the context of Covid-19: first update, ECDC, November 2020

- CIBSE Covid-19 Ventilation Guidance, v4, October 2020

- PR EN308 Heat exchangers – test procedures for establishing performance of air-to-air and flue gases heat recovery devices, May 2020

- REHVA Covid-19 specific guidance document. Limiting internal air leakages across the rotary heat exchanger. July 2020

- EN 16798-3 Ventilation for buildings. Part 3: For non-residential buildings. Performance requirements for ventilation systems, December 2018

- Eurovent 6/15 – 2020 Air leakages in air handling units. Guidelines for improving indoor air quality and correcting performance. 1st edition, 1 April 2020