Heat from sewage water can be extracted using large-scale heat pumps

So much heat produced in the UK is going to waste. The list of culprits is long: food industries, cement factories, warehouses, leisure centres, sewage plants and waste-incineration sites are among the facilities producing heat that is not used – but it does not have to be that way.

In Sweden, there are several examples of waste heat being reused to produce heating and hot water. The use of waste heat is enabled by the country’s district heating infrastructure, which, in 2016, supplied more than 57% of all buildings in Sweden with heat and hot water. Based on statistics gathered from Swedish district heating producers, more than 45% of all the heating generated in 2018 came from sources of waste heat.

District heating, often referred to as a heat network, relies on a network of pipes to transport heat to individual buildings and dwellings from a centralised source of production. Heat exchangers in individual buildings and/or dwellings extract heat from the hot water, and this is then recirculated as cool water to the central production.

The source of heat at the central production varies. It can be a boiler or combined heat and power (CHP) system, but it can also be a heat pump or a heat exchanger. These last two examples are highly relevant for waste heat.

I work for a specialist consultancy dealing exclusively with heat networks. As part of my role, I visit existing developments with heat networks, as well as developments under construction. In many cases, the new developments are built with natural gas-based heat networks, despite being next door, literally, to a facility that is generating waste heat.

Given the significant impact it has had on heating provision in my native country, I can’t help but wonder why more effort has not been made to use waste heat in the UK.

As the potential for waste heat in the UK energy system is largely unknown, I prepared a case study for the CIBSE Technical Symposium that aims to create a basis for discussion around the potential for waste heat in the UK.

Incorporating unutilised waste heat into district heating production1 investigates what effect using Swedish techniques for waste-heat recuperation would have on the UK heat supply and its associated emissions.

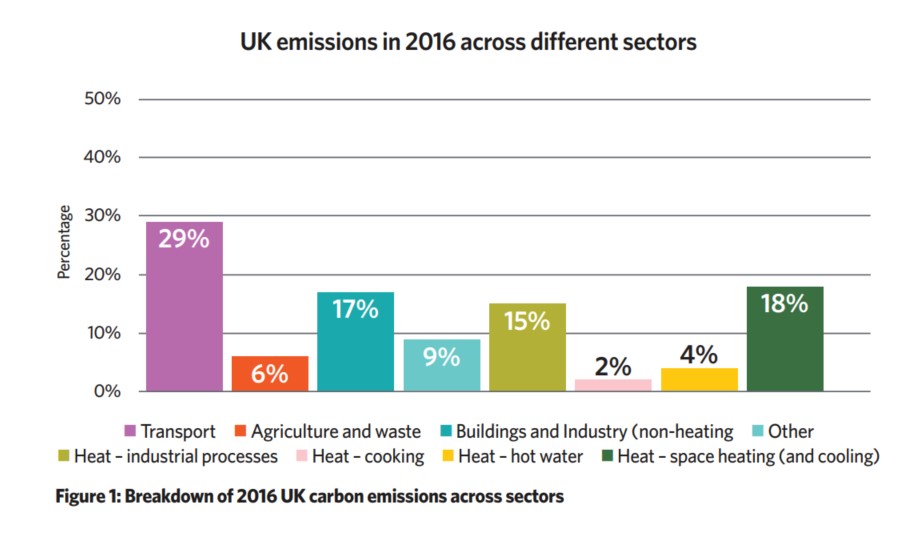

According to a report from the Department for Business, Energy and Industrial Strategy, published in 2018, net UK emissions in 2016 amounted to 468Mt CO2e. Heat demand is the biggest source of the country’s carbon emissions, with about 46% of the heat demand used for space heating and cooling. Figure 1 displays the breakdown of 2016 UK carbon emissions across sectors.

To recuperate waste heat from industries, heat extraction can be made possible via a heat exchanger. For industries outside of the metallic, mineral and chemical sectors, the majority of waste heat potential is available in the temperature range of 100°C to 200°C, which is suitable for recuperation into district heating production. An estimated 9TWh of waste heat in this temperature range is currently unused in the UK industrial sector.1

One potential approach to recuperating waste heat created in dwellings is through using heat in wastewater. Warm wastewater is created from everyday activities such as showering, washing hands and cleaning dishes, and residual heat can be recovered in the treatment plant.

The treatment process will make use of some of this residual heat to provide optimal process conditions for bacteria and microorganisms.

Even after the treatment process, there will be a significant amount of heat that can be recovered. How much will depend on the temperature profiles of the treatment plant and the outlet destination of the treated water.

Thames Water treats the sewage water of 15 million customers, with a significant potential of unused waste heat, which could be extracted using large-scale heat pumps.

If a similar ratio of heat available per capacity of treated wastewater was assumed for a plant operating in the south of Sweden, extracting the residual heat in the wastewater treated by Thames Water could provide 10TWh annually.

Heat from waste incineration

In 2018, 10.9 million tonnes of rubbish were incinerated in the UK, but most facilities do not recover heat from the incineration process. Sweden recovers the most energy from incinerated waste in Europe, with about 3MWh of energy recovered per tonne of waste.

Reuse of heat from UK waste-incineration facilities is relatively uncommon. There are several UK organisations that pay bodies in other countries to receive large volumes of household waste.

Waste-incineration facilities in the UK will increase in the future. To ensure this is done in a sustainable manner, the percentage of recycled materials will need to increase, as well as the amount of energy recovered from each tonne of incinerated waste.

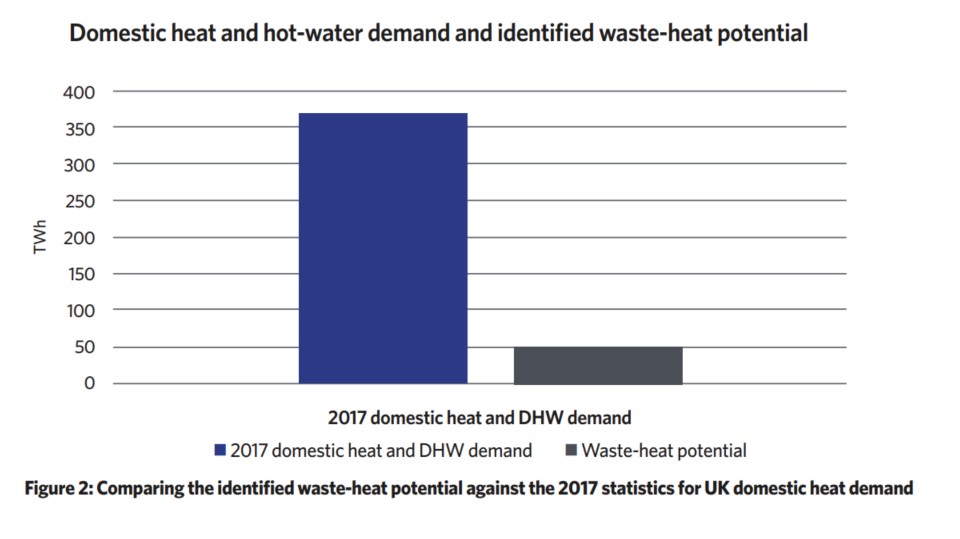

The waste-heat potential from the UK industrial sector, wastewater treatment facilities in southeast England, and heat-recovery potential from existing waste-incineration facilities would be 51.7TWh annually, assuming the performance figures of operational facilities in Sweden.

This equates to 14% of UK homes’ total heating and hot-water demand (see Figure 2). By using waste heat to heat UK homes, offices and hot water, the need for natural gas would reduce significantly.

By displacing production of heat – away from, for example domestic gas boilers – the total carbon emissions of the UK could be reduced by 3%, despite the study only investigating a limited fraction of the available potential.

Provision of heat to buildings from district heating is targeted by the UK government to increase from 2% in 2018 to 18% by 2050. The investment cost of this will be several billions of pounds, where a significant portion of the capital invested in district heating goes towards enabling the generation of heat. But what if there was no need to generate new heat to supply a district heating network?

To enable this energy to be recovered, there will need to be an incentive. District heating infrastructure will not only enable waste heat to be transferred, but it will also enable one organisation to pay another to buy waste heat.

External incentives could help, such as changing how energy efficiency requirements in planning permissions are formulated, and how waste energy and materials are taxed.

As district heating solutions are built, it will be necessary to consider how they interact with existing building stock, infrastructure and surrounding solutions. It makes environmental sense to think of the significant supply of waste heat as a source of production.

■ Lina Aglén is a lead engineer at FairHeat

Reference:

1: Industrial waste heat: estimation of the technically available resource in the EU per industrial sector, temperature level and country, Applied Thermal Engineering, 2018