The size of the Sunamp heat battery compared with a hot-water cylinder

In November 2020, the UK Prime Minister announced an eye-catching plan to ramp up heat-pump installations across the nation, as part of an initiative to decarbonise domestic heating. The headline target was for 600,000 heat pumps a year to be installed by 2028.

New-build homes might account for around 100,000 of these installations, but the majority will have to be retrofitted in existing homes. In many ways, this looks like a challenging target, as current levels of installations – although climbing sharply – are still in the low tens of thousands a year. There are, however, reasons to be optimistic, as the problem is mostly not a technical one.

Domestic air source heat pumps (ASHPs) are a mature technology and are being produced in quantity by large multinational companies such as Mitsubishi, Samsung, Daikin and Vaillant. Installing a monobloc heat pump may require more work, but it’s not much more technically challenging than a boiler once installers have built up some familiarity with the technology.

Nonetheless, there are a number of small technical and practical issues to overcome for many heat-pump retrofit projects. These were identified by the Department for Business, Energy and Industrial Strategy as part of its ‘Electrification of heat’ demonstrator project – a national project in which heat pumps have been installed in a significant number of homes to better understand the issues and investigate solutions (see panel, ‘Heat pump challenges to overcome’).

Heat storage

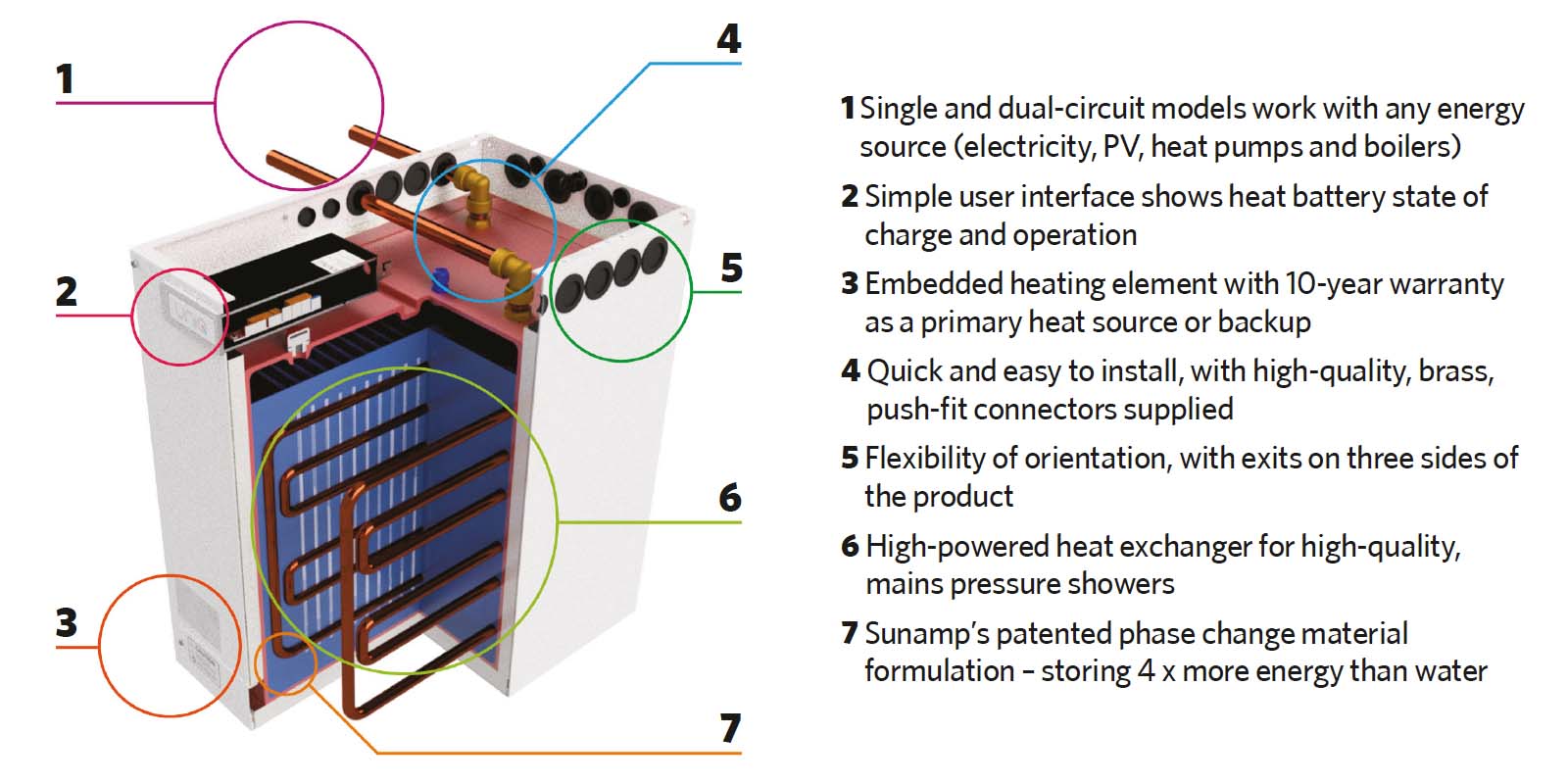

One of the participants in the project is Sunamp, an innovative Scottish heat-storage company that has developed a phase-change heat battery system that enables much more compact storage of energy for hot water. It produces a range of heat batteries, designed to act as replacements for direct and indirect hot-water cylinders.

The heat battery is essentially a block of sodium acetate with a melting point of 58°C (PCM58). Energy is stored by melting the PCM58 using heat from an electric heating element or an indirect coil run through the store.

To extract the heat as hot water, a second coil is in the block – cold water goes in, hot water comes out just below the melting point of the PCM58, at 55°C. The heat batteries have a smaller surface area and are encased in vacuum insulation panels, so their standing losses are small compared with a cylinder – ~30W depending on size.

The indirectly heated heat batteries work with a range of heat pumps currently on the market, and could be a facilitating technology for heat pumps to be deployed in more dwellings. While a 210-litre cylinder is around 550mm in diameter and 1,500mm high, a heat-battery unit of equivalent storage capacity is 365mm wide x 575mm deep x 856mm high – little more than half the size of a standard domestic washing machine.

The fact that it is a thermal store, rather than an indirect cylinder, means there are two heat-transfer processes: 65°C low temperature hot water (LTHW) to 58°C PCM to 55°C water. For an indirect cylinder, it is one: 60°C LTHW to 55°C water.

So, to get the same temperature of hot water, the heat pump needs to run hotter in hot-water mode, with a resultant drop in coefficient of performance. This is somewhat offset by the fact that heat-battery units do not need a legionella pasteurisation cycle and have lower standing heat losses.

Heat pump challenges to overcome

Flow temperatures and radiator sizes – Heat pumps don’t run as hot as boilers, and many houses may need radiators replaced when they get a heat pump retrofitted – anecdotally, about 30% of radiators on average. The radiator industry is responding to this challenge; some have three radiator panels and three sets of convection fins, while others have fanned units for getting higher outputs out of small wall spaces.

Noise – Modern ASHPs are very quiet, but care is still needed to ensure they don’t cause a nuisance. To meet the requirements for permitted development rights, a heat pump must adhere to the MCS 020 calculation limits. In cases where the requirements are difficult to meet, it may be possible to use acoustic enclosures or screens. Once installed, many units allow the user to schedule quiet-mode (with reduced output).

Outside space – Not all houses have space for a heat pump. This can be overcome by wall-mounting heat pumps or making adaptations to the outdoor space. If this is not possible, electrifying heat will probably require district heating or direct electric heating.

Inside space – Heat pumps have lower outputs than combi boilers, so need hot-water storage of some sort. In most cases, this is an unvented indirect cylinder, heated by a large surface area coil. But with people having switched to combi boilers, only about a third of UK homes now having a hot-water cylinder4. Some houses without space need another solution – such as a compact thermal-energy storage system.

Existing pipework – Some existing heating system pipework can make heat pump retrofits extra challenging. Heat pump COPs are best when they can operate at a 5K temperature difference which means a lot of flow. Microbore pipework can require reworking of the heating distribution.

Installation

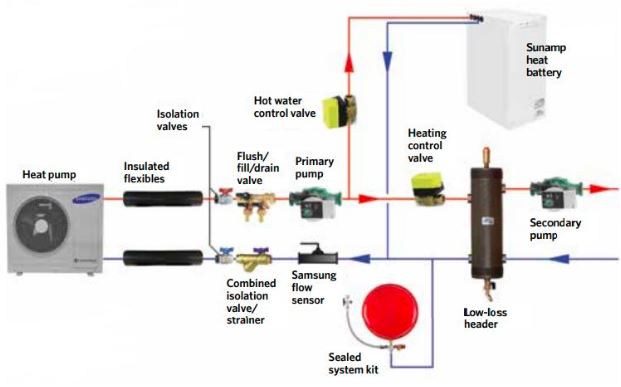

Installation of a heat battery as hot-water storage with a heat pump is only slightly more complex than installing an unvented cylinder; not being a pressure vessel, they are inherently safer than an unvented cylinder.

Exploded diagram of the Sunamp battery

This means that, under Approved Document G – Sanitation, hot water safety and water efficiency, there are no safety valves and, hence, no discharge tundish requiring drainage. Wiring the heat-battery unit up with a heat pump is a little more complex, however.

A heat-pump controller normally comes with a temperature probe to put in a pocket in the cylinder, enabling the heat pump to optimise the hot-water cycle – but there is no such pocket with the heat battery.

Instead, the heat pump temperature probe has to be cut off, and the wires terminated into the heat-battery controller so the battery’s controller can ‘spoof’ the resistances, making the heat pump think it is looking at a hot or cold cylinder.

The main challenge of this thermal battery is the weight. Whereas an unvented cylinder arrives at site empty, weighing around 50kg, this heat battery arrives at site at its full weight of 184kg for a 212-litre equivalent, so manoeuvring a unit into position can be difficult. Sometimes specialist delivery equipment may be required if the installation location is upstairs. The best option could be to put one in a less conventional place – for example, under the stairs, in a kitchen, or in a utility room.

Schematic showing system with air source heat pump and heat battery

A whole array of innovations, small and large, will be needed to help us transition away from fossil-fuel heating. Domestic heating engineers will need to adapt as new solutions come to market, and there will need to be a lot of training and upskilling of the workforce. Despite all the challenges that ramping up heat-pump deployment brings, however, a variety of organisations are working hard, innovating and trying to overcome all the obstacles on the path to more sustainable heating solutions.

Jez Climas is head of renewable heat at Midsummer

References:

- 600,000 heat pumps to be installed by 2028 under Government’s Green Plan, ACR News, November 2020.

- Renewing Britain: the changing landscape of home-grown energy, MCS Charitable Foundation, March 2021.

- Electrification of Heat UK demonstration project, Catapult Energy Systems.

- English housing survey: headline report 2019-20, Ministry of Housing, Communities and Local Government.