A group of companies is testing a heat pump system combined with solar panels and phase change materials to offer occupants energy efficient heating and cooling. Currently, only 0.5% of UK homes have air conditioning, but, for those that do, cooling represents around 30% of total energy consumption.

The new system, funded by InnovateUK, is known as Total Heat Energy and Moist Air Control (Themac) and aims to reduce significantly the energy required for cooling, if required. Its goal is to maintain temperature and humidity within a building – throughout diurnal, seasonal and occupancy changes – while supplying hot water and heating from a renewable source.

The consortium consists of specialists in their respective fields: PCM Products, involved with phase change materials (PCMs); heat pump manufacturer Arkaya Energy; renewable housing developer Positive Homes; and a research institute in the University of Nottingham.

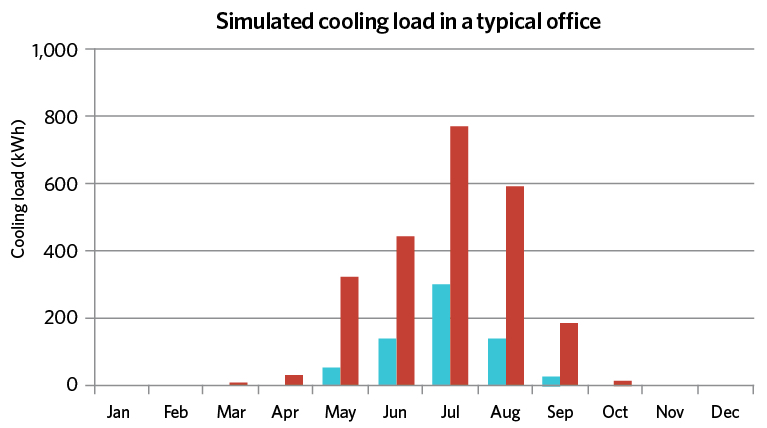

Figure 1: The red bars show the cooling demand for a typical office; the blue bars show the demand in the same office for cooling if the PCM passive cooling is installed

Its tri-modular approach aims to achieve a complete comfort solution. A high-performance heat pump supplies sufficient heating in winter and can provide domestic hot water. A super-water-absorbent, polymer-based desiccant is able to humidify or dehumidify the air, thereby maintaining relative humidity at a comfortable level. Finally, a passive PCM system helps prevent overheating during summer days while maintaining a habitable temperature overnight.

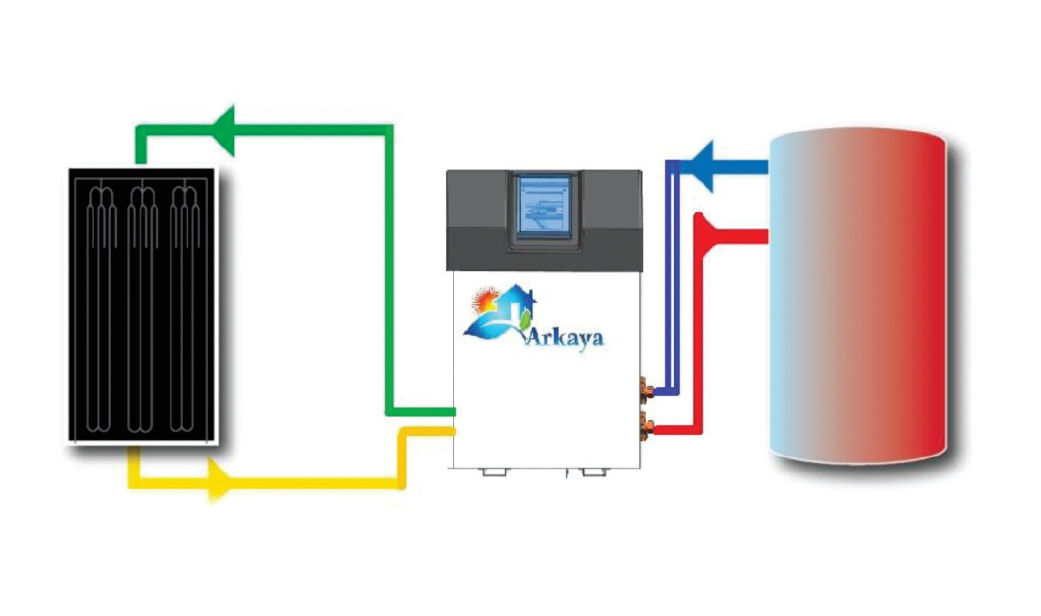

The Arkaya Energy heat pump is combined with solar thermal panels that can be mounted on roofs or walls. They draw thermal energy from the environment, even in the absence of direct solar irradiance. This gives the overall system a higher coefficient of performance (COP) than traditional systems, and it can reach temperatures of up to 68°C all year round with little decrease in efficiency.

Figure 2: Basic layout of the solar-assisted heat pump, with the solar thermal panels on the left and the smart box in the centre

The heat pump has two cycles – a water cycle and a refrigerant cycle with a heat exchanger in between – and a sensor monitors these to minimise heat loss. The system works at a higher pressure than most heat pumps, which improves COP and reduces heat losses in winter and overnight. The high temperatures allow the heat pump to supply energy directly to traditional radiators.

The technology is contained within a ‘smart box’, which can be put in lofts, cupboards or even outdoors. This, combined with minimal servicing requirements, offers consumers a user-friendly solution.

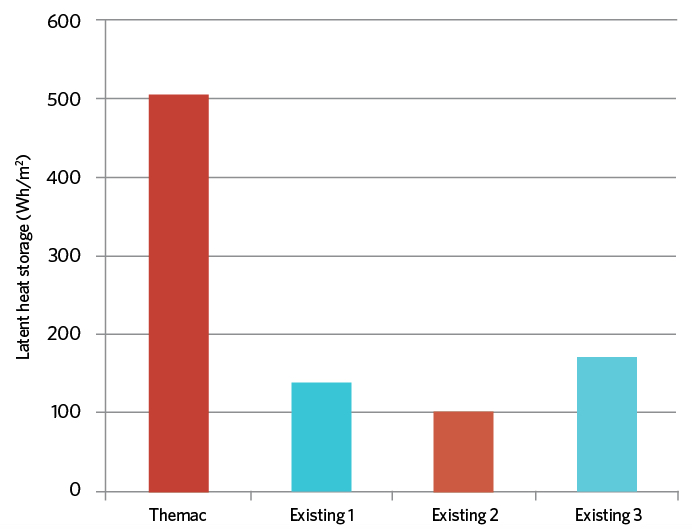

PCM passive cooling is the second technology in the system. The PCM – normally fitted in the ceiling cavity or above ceiling tiles – melts and absorbs heat at 27°C, allowing it to remove excess heat from the air at the top of the room, keeping the air lower down at a comfortable level. The PCM is designed to provide all the necessary cooling; the heat pump will not offer any mechanical cooling.

At the end of the day, as temperatures drop, cool air is passed around the PCM to allow it to refreeze. An air vent allows the night air to circulate around the PCM for refreezing. PCMs are not fast-reacting materials, so it is not necessary to have fans blowing air over them – natural air movement is sufficient. The same process is repeated the next day and room temperatures are maintained at a comfortable level during the night.

Figure 3: The amount of latent heat that can be stored in the PCM per m2 compared with existing systems

The water super-absorbent polymer (wSAP), used for humidity control, works in a similarly passive way to the PCM. As the room humidity rises, the wSAP (commonly sodium acrylate) absorbs excess moisture from the air; this can then be naturally released back into the room if humidity drops too low. The heat pump is linked to the wSAP material, so it can be regenerated should it become saturated.

As a result of the modular arrangement, each individual unit can perform as a stand-alone. Currently, the combined system is estimated to achieve a 51% reduction in energy consumption for heating (based on the simulations for a conventional gas central heating system compared with the heating provided by the heat pump) while offering an energy-free cooling solution.

Six months of lab testing will take place soon, before the system is installed in a three-bed home in summer 2019, where it will be monitored until August 2020.

- Sam Gledhill is a chemical engineer at PCM Products