UK heat and hot-water systems examined contain an average of 9kgCO2e per kg of product weight

New research for CIBSE has uncovered the significant amount of embodied carbon in heat and hot-water systems in UK homes. The study, undertaken by Elementa Consulting, revealed an average measure of 9kgCO2e per kg of product weight in the systems examined. This represents between 3% and 25% (excluding refrigerant leakage) of the whole-life embodied carbon of a building.

The research is due to be published as a Technical Memorandum (TM65.1) in winter 2021. It was conducted to provide recommendations on how engineers might consider and reduce embodied carbon in MEP equipment, which has a significant embodied carbon impact when a building is first constructed, and during its lifetime because of high equipment replacement rates.

CIBSE TM65, published in January 2020, has an embodied carbon calculation methodology for building services products, to be used where no Environmental Product Declarations are available. Engineers must understand the embodied carbon emissions of the systems they design and the products they specify, so informed choices can be made using ‘whole-life carbon’ thinking. Supply chain collaboration is particularly important when considering heating systems of residential schemes.

Study aims

The study focused on heating in residential new builds with ultra-low energy building fabric (aligned with the Passivhaus fabric performance). The following residential typologies were explored:

- Three-bed, five-person terraced house

- Two-bed, three-person flat in multi-residential building of 15 units, 100 units

- Large development of 10 buildings, each with 200 units.

Around 30 product types were explored. In total, 70 data points were collected, and 29 manufacturers provided information to enable ‘basic’ or ‘mid-level’ calculations to be carried out for their products. See Section 2 of TM65.1 for additional details on the data points collected. Information provided in the TM65 manufacturer form was used to carry out a ‘basic’ or ‘mid-level’ calculation. In most cases, meetings were held with technical representatives of manufacturer companies, to break down the information required and explain the benefit of sharing it. Individual results were shared with each person of contact so that manufacturers could understand the embodied carbon impact of their product(s). The remaining products were kept anonymous.

A range of products was selected to represent the most used heating and hot-water systems in new-build residential schemes in the UK. Equipment studied fell into the following categories: individual heat-generation systems; central plant heat generation; heat emitters and heat exchangers; heat distribution; hot-water storage; hot-water distribution; ancillaries; and mechanical ventilation with heat recovery. In each instance, different capacities were requested, reasonably sized to suit the residential schemes included in this study. In addition, a functional unit was assigned to each product based on the most common unit of measuring capacity.

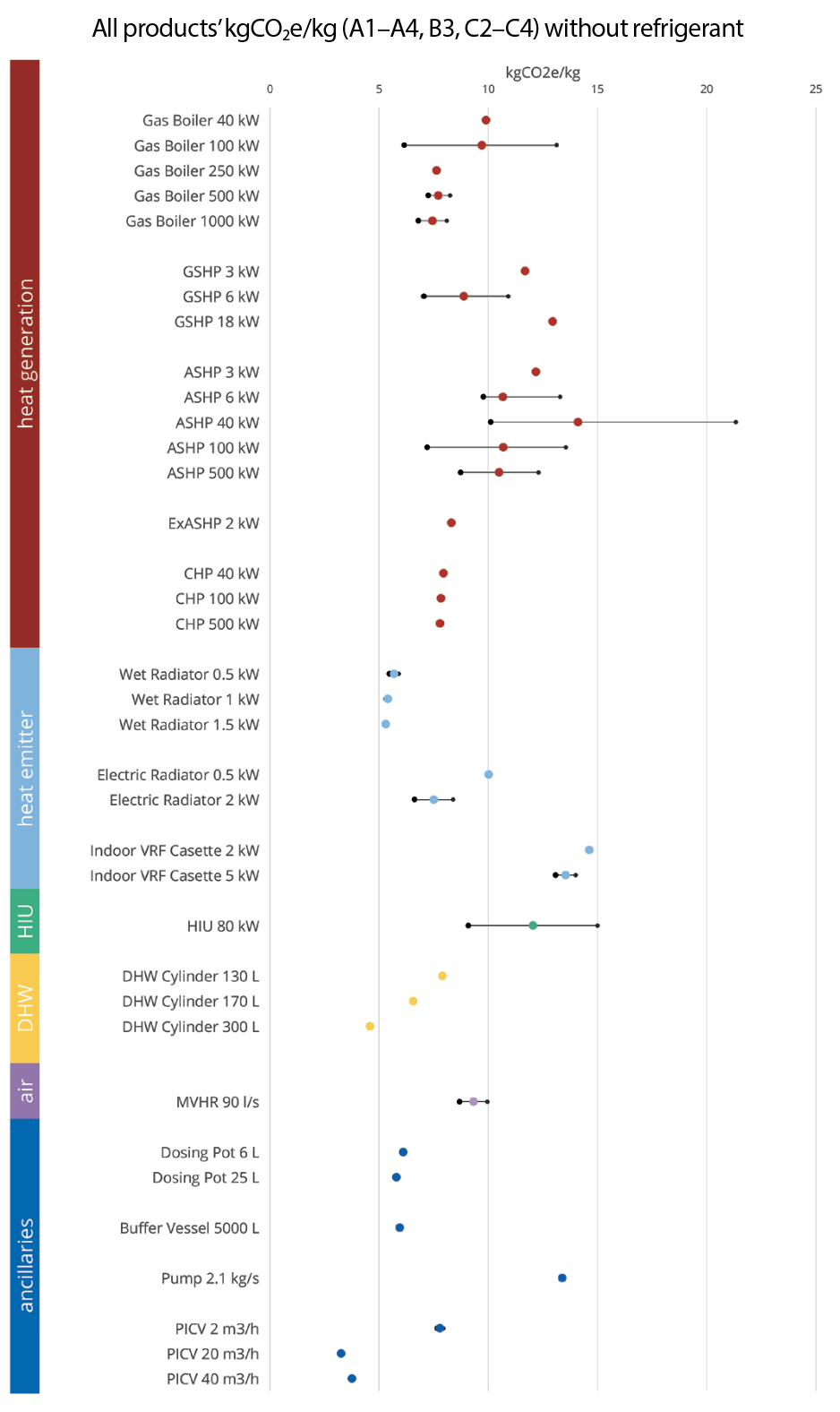

Figure 1: Embodied carbon kgCO2e/kg for all products (A1-A4, B3, C2-C4) without refrigerant

The range of embodied carbon impact (at product level) by weight of products investigated is estimated between 3kgCO2e/kg and 21kgCO2e/kg, and the average is 9kgCO2e/kg (excluding refrigerant). See Figure 1 for a summary of all the kgCO2e/kg covered in the study. Capacity buckets were created to calculate generic data points that should be used for system-level calculations.

The study concluded that heat-generation equipment can account for 5-60% of the embodied carbon (stage A, B, C) of a heating and hot-water system (excluding refrigerant leakage), and heat emitters 10-50%.

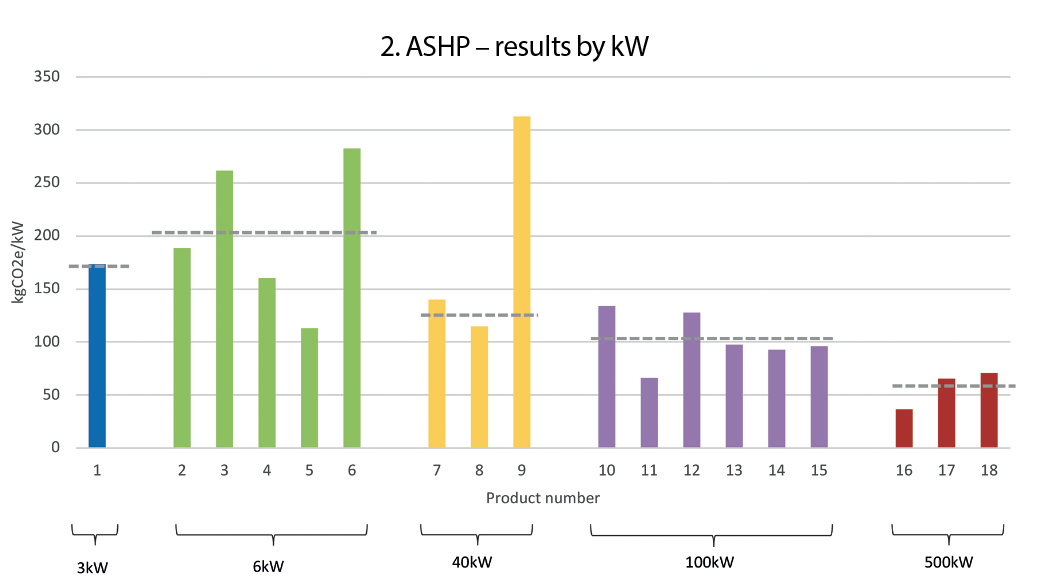

In the appendix of the TM65.1 document, the results for each product are given in four graphs. Figure 2 is one of these graphs for air-to-water air source heat pumps (ASHPs). It shows the results for an ASHP between 3kW and 500kW, with 18 data points collected from nine manufacturers. The graph shows that the larger ASHPs have a lower kgCO2e/kW than smaller-capacity ASHPs.

System-level calculations were carried out by multiplying the product-level embodied carbon results by the quantities for each residential typology. Individual and communal heating strategies were explored across the four residential typologies. The individual systems included a gas boiler baseline, heat pumps, VRF, direct electric, and exhaust air heat pump; the communal systems included an active ambient loop, passive ground loop, and connection to a district heating scheme. See Figure 3 for the embodied carbon emissions for a range of systems in a 100-unit residential development.

The range of embodied carbon impact in kgCO2e/m2 is large in the scenarios explored in this study. In a multi-residential development, the strategy with the lowest embodied carbon, excluding refrigerant leakage, is direct electric, with 36kgCO2e/m2, and the highest is an active ambient loop in a 15-unit scheme, at 201kgCO2e/m2.

For upfront embodied carbon (A1-A5), heating and hot-water systems could represent between 1% and 9%.1 For total embodied carbon (A, B, C) over 60 years, they could represent between 3% and 25% (excluding refrigerant leakage). In the case of a VRF system with R134a, the embodied carbon impact of the heating and hot-water system is above the current best-practice whole-building target when refrigerant leakage is included (832kgCO2e/m2).

When excluding refrigerant leakage, an active ambient loop has the highest embodied carbon impact. As residential schemes get larger, the uplift compared with other systems is reduced. It is important to note that active ambient loops can have very low operational carbon emissions.

The dotted line indicates the average generic embodied carbon value.

Figure 2: Embodied carbon emissions for different sizes of ASHPs

Refrigerant leakage can be significant.

This is especially true for VRF systems where the evaporator and condenser are split, with refrigerant piped through the building. Factory-sealed heat pumps should be prioritised, and low global warming potential refrigerants used.2 Refrigerant choice can increase the embodied carbon impact of a VRF system by a factor of nine and of a heat pump system by 30%.

The study also explored the impact of a business-as-usual (BAU) fabric (based on a space heating peak load of 30W/m2) on the embodied carbon impact of two heating strategies: a gas boiler and an ASHP for a terraced house.

For the ASHP scenario, the upfront embodied carbon increases by 75% when the terraced house has a BAU fabric compared with an ultra-low energy fabric.

HVAC study for office refurbishments

Over the next six months, CIBSE and Elementa will concentrate on heating, ventilation, and cooling systems in commercial schemes, to develop TM65.2 Embodied carbon of HVAC systems in offices.

As part of this study, information on the material breakdown of various HVAC products is needed from manufacturers. Those that provide information will be acknowledged in TM65.2 (see panel, ‘Embodied carbon webinar for manufacturers’).

Embodied carbon webinar for manufacturers

Join a CIBSE webinar on 2 November to find out more about the study and to get involved in the next phase of research on office embodied energy. This is an opportunity for manufacturers to position their respective business as a leader in the field of embodied carbon and to be promoted through CIBSE-sponsored research activities. Register at bit.ly/CJNov21TM65

The webinar will offer:

- An overview of CIBSE TM65

- A preview of TM65.1 – residential heating, which will be published soon

- Details of the scope of TM65.2 – commercial offices

- More on how manufacturers can support this study and the benefits of participation.

Please send any complete TM65 manufacturer forms and reporting forms to CIBSE at embodiedcarbon@cibse.org to help contribute to this database.

Definition of embodied carbon

Embodied carbon is the carbon emissions associated with materials and construction processes throughout the whole life-cycle of a building or infrastructure. Embodied carbon includes:

Product stage: A1 Material extraction; A2 Transport; A3 Manufacturing

Construction process stage: A4 Transport to site; A5 Construction

Use stage: B1 Use; B2 Maintenance; B3 Repair; B4 Replacement; B5 Refurbishment; B6 Operational energy use; B7 Operational water use

End-of-life stage: C1 Deconstruction; C2 Transport to end-of-life facilities; C3 Waste processing; C4 Disposal

Benefits beyond the system boundary (D): Reuse, recovery, recycling potential. Upfront carbon is the term given to emissions caused in the materials production and construction phases (A1-5) of the life-cycle, before the building or infrastructure begins to be used. These emissions have already been released into the atmosphere before the building is occupied or the infrastructure begins operation.

References:

- This assumes the embodied carbon impact of a new home is 800kgCO2e/m2 based on a LETI C rating (LETI, 2021). This was chosen because it represents current best practice for buildings being designed today.

- Refrigerants and environmental impacts: A best practice guide, Hamot et al, 2020, bit.ly/CJNov21ref

- Many thanks to the following manufacturers that contributed information to the TM65.1 study: Vaillant, Lochinvar, Ideal, Hamworthy, Upton, Stratton, Aldrich, Fulton, Glen Dimplex, Mitsubishi, Daikin, Rhoss, Kensa, Nilan, Merriott, Stelrad, Cetetherm, Rhico, ACV, Flamco, Swegon, Danfoss, Recoup, Kingspan and Uponor.

- Yara Machnouk is a graduate environmental designer and was a runner-up in last month’s CIBSE ASHRAE Graduate of the Year award