Deep Green Energy CEO Mark Bjornsgaard believes it makes sense to heat pools using waste heat from data centres

Data centres have become ubiquitous in our society, supporting most of our daily activities. They are essential to the functioning of the internet and the digital economy. However, data centres consume vast amounts of energy, with the industry accounting for 3% of global carbon emissions – which is more than aviation – and generating an estimated 4.51GW of waste heat in the UK each year.

One company, at least, has found an effective way of capturing some of this waste heat. Deep Green Energy has developed a technology that uses the waste heat generated by small-scale, local data centres and repurposes it to heat swimming pools and other buildings.

A recently completed project involved the installation of a small-scale data centre at a public swimming pool in Exmouth Leisure Centre, in Devon. It is expected to save the operator £22,000 in heating bills over the next year by using waste heat to warm the pool to 30°C for 60% of the time.

This is the first commercial pool project that Deep Green has commissioned, but it will be the first of many, according to Deep Green Energy CEO Mark Bjornsgaard. ‘We’ve got seven more signed, and what seems like every swimming pool in the northern hemisphere expressing an interest. I’d love to think that we can work with up to 40 sites this year,’ he says.

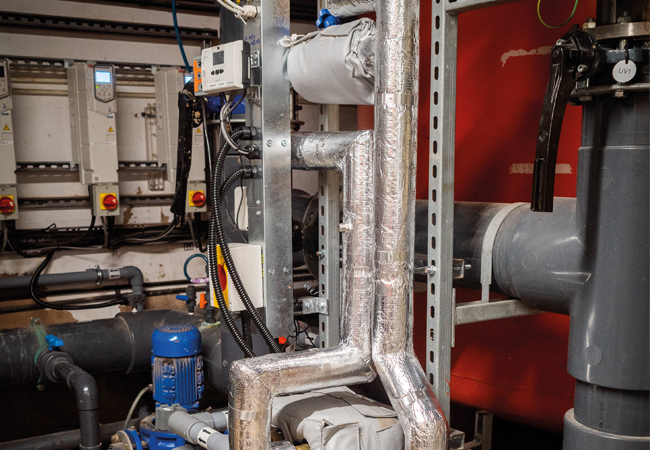

Deep Green has been planning and building prototypes for the past six years, and the company is responsible for the industrial plumbing going into the non-standard swimming pool environment.

Deep Green does ‘the difficult last-mile bit’ when it comes to installing the necessary equipment

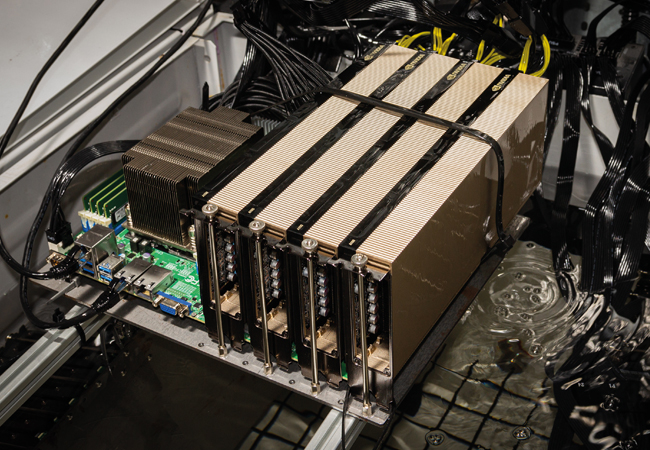

Immersion cooling technology is used to capture the heat from the data centres. This involves immersing entire computers in oil, instead of blowing cold air over them to keep them cool, ensuring all components – including the chip – are cooled efficiently, with no need for further ambient cooling. The hot oil is then flowed through a heat exchanger, and water from the swimming pool also flows through it to be heated. Unlike normal data centres, all of the pipes are lagged to make sure as much heat as possible gets reused.

Hopefully, we can get every swimming pool in the UK heated like this. It makes sense, especially with the cost savings. Why wouldn’t you?

Capturing heat from data centres is not a new idea. Microsoft wrote about it in a white paper in 2011, coining the term ‘data furnace’. Although it has been discussed before, says Bjornsgaard, it has not been widely implemented. ‘In terms of the technology, it’s all totally interchangeable. It’s not anything crazy; everything we’re using is known; it’s scalable. It’s just a computer in oil and a heat exchanger,’ he says.

Deep Green’s units are edge sites – smaller data centres built very close to where people live and work. The installation in Exmouth Leisure Centre, for example, is the size of a washing machine. Really fast local connections can only be done with an edge network, ensuring low latency, which is the delay before a transfer of data begins after an instruction.

By reusing heat from mini data centres, Deep Green’s technology means less energy is required to cool larger data centres. ‘Getting computers out of big data centres and into local communities is the way forward,’ explains Bjornsgaard. ‘In 10 years’ time, we’ll need Deep Green units in swimming pools to provide the data needed to render graphics for nearby virtual reality applications, for example.’

Using edge servers means no complicated pipe network process is involved in the installation. ‘We’re breaking up the data centre and taking the heat to where it’s needed,’ says Bjornsgaard. ‘For example, the pipes in the Exmouth installation are only 3 metres away from the computers.

‘There are lots of variables to consider when you land in a swimming pool pump room. Is grid capacity enough to power the installation? Can we get sufficient internet connectivity? Can the pool use 100% of the heat produced?’

Reusing heat from data centres makes particular sense for swimming pools, he adds, which lose approximately 1°C per hour, regardless of the external temperature, and data centres produce heat 24 hours a day, so there is a consistent heat source for the pool.

Immersion cooling technology is used to capture heat from the data centres

Using Deep Green’s technology to heat a pool has another benefit. ‘The oil is brilliant protection,’ says Bjornsgaard. ‘Data centres create harsh environments; where you have chlorine contaminates and copper interacting, for example, this will eventually cause corrosion of materials. So, the great thing about immersion is that it will protect the equipment.’

Bjornsgaard believes adoption of the technology will be exponential, but sees a major barrier being people’s reluctance to break from the norm.

‘We have always built data centres with evaporative cooling and cold floors, but now we are saying you have to pipe all this hot oil around your computers. Lots of people will have a natural resistance to this at first, but once they see how well it works, I think interest will peak,’ he says.

Bjornsgaard has ambitious targets for Deep Green’s units and wants to roll out the technology to all pools in the UK. ‘There are one and a half thousand public swimming pools in the UK. Hopefully, in the next five years, we can get every swimming pool heated like this. It makes sense, especially with the cost savings. Why wouldn’t you?,’ he says

The company has a mission to replace all data centres without heat recapture by 2035, with these ‘digital boilers’ making a significant dent in carbon emissions caused by the data centre industry.

The task is daunting, Bjornsgaard admits, but with the scalability and adaptability of the technology for various applications, it is achievable.

Expanding the horizons

Deep Green has begun drafting detailed plans to implement this technology in other sectors that can effectively use large amounts of low- or medium-grade heat, including commercial and industrial sites, and domestic heating systems. ‘In homes and offices, 17% of carbon emissions comes from heating; that’s the bigger market for heat,’ says Bjornsgaard.

‘We already have district heating systems in place, and every district heating system – every office block with a centralised boiler – could harness the power of a digital boiler.’

An even bigger sector will be implementing data centres next to heat pumps. ‘Slaving a Deep Green unit to a heat pump with a thermal store makes the heat pump really efficient,’ says Bjornsgaard. ‘That’s where we want to go with the technology; the retrofit opportunity is enormous.’

Waste heat would provide pre-heat to a heat source. That can be as simple as heating up the inlet water on a water source heat pump or heating a buffer tank or heat store, which is then drawn from by the heat pump when needed. This pre-heat would narrow the temperature difference for the heat pump, making the heat pump more efficient and increasing the available heat.

‘As the cloud market grows, the number of data centres – and the heat they produce – will grow. The heat pump market is also projected to grow. So there’s a huge opportunity here if we match up the size of the cloud market with the size of the heat-demand market, and the potential for heating with our units,’ says Bjornsgaard.