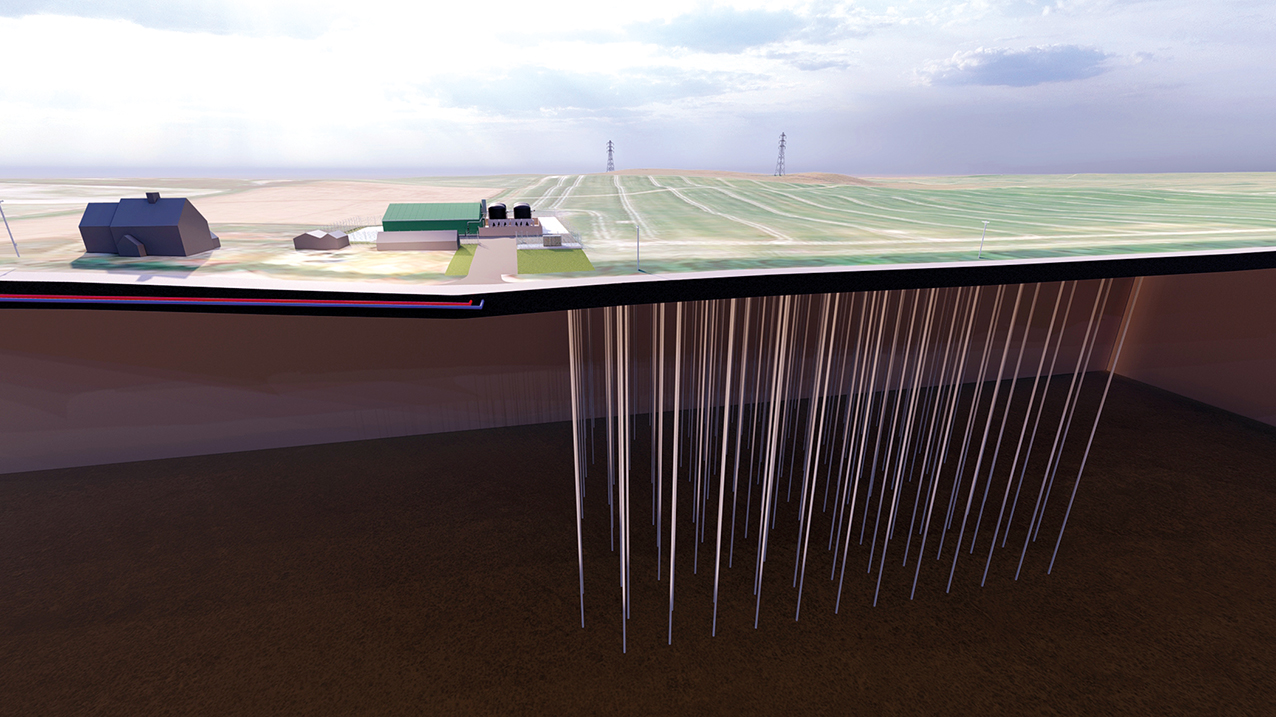

The energy centre and the field containing the ground arrays can be glimpsed in the top right-hand corner

On 19 October 2021, the government launched a consultation (now closed) on its plans to phase out, from 2026, the installation of fossil-fuel heating in the 1.1 million homes in England not connected to the gas grid. It also plans a ‘heat pump first’ approach to replacement heating systems from that date.

A community heat network nearing completion at Swaffham Prior, East Cambridgeshire, shows how it is possible to phase out fossil-fuel heating in rural villages; it also highlights some of the challenges faced by those attempting to do so cost-effectively.

A particular issue with homes that use heating oil is that fuel delivery notes are often the only consumption data available

Installation of heating mains and the construction of a local renewable energy centre are under way in Swaffham Prior, for what will be England’s first rural village heat network. The majority of its 300 homes – as well as two churches, a pub and school – are currently heated using oil, one of the most carbon-intensive forms of heating. The remainder of the properties use liquefied petroleum gas (LPG) or direct electric.

In spring 2022, the first homes will connect to the heat network and benefit from low carbon heat produced by a hybrid air and ground source heat pump (GSHP) system, powered by a solar farm 8km away. Four large thermal stores will meet short-term peaks in demand and provide resilience.

The Heating Swaffham Prior project was kick-started by Swaffham Prior Community Land Trust to give residents the opportunity to cost-effectively replace their oil-fired heating systems with a low-carbon alternative. In 2018, the trust commissioned a study into alternative heating options from sustainability charity Bioregional, which identified the potential for a village-wide heat network. A range of heat sources was considered – including biomass from local straw – but the key to unlocking the project was a parcel of land on the edge of the village owned by Cambridgeshire County Council (CCC). This opened up the possibility of generating heat using a GSHP system.

CCC partnered with the trust, enabling the project to access funding and support from the Department for Business, Energy and Industrial Strategy’s Heat Network Delivery Unit. It also allowed CCC to appoint sustainability and environmental consultancy Avieco as project manager, and Bouygues E&S Solutions as design and development engineer.

Residents will be able to connect to the heat network from the spring

CCC set out to establish the level of interest in the project. Avieco worked with LineUndrawn to engage the wider community and secure sign-ups for the scheme. ‘Because the project is a retrofit of privately owned homes, we needed to do an intensive piece of community engagement, to see how many homes wanted low carbon heat and what the connection issues would be,’ says Helen Troup, principal consultant at Avieco. In just six months, more than half the community had registered an interest in the scheme.

Next, the challenge was to establish the likely heat demand. Troup says one of the key learnings from Swaffham Prior is that heat-demand assessment is difficult. A particular issue with homes that use heating oil is that fuel delivery notes are often the only consumption data available; there is no information on when and how often the heating system is used.

Back-up heating

The original concept for Swaffham Prior used LPG boilers as the back-up heat source , but CCC was reluctant to include fossil-fuelled heating in the scheme, given the aspiration for carbon neutrality.

Back-up heat pumps were also dismissed because of high costs. ‘We were reluctant to put forward an entirely heat pump-led scheme because of the redundancy. A large proportion of the plant’s capacity would have been largely obsolete, and would have dug a hole in the budget,’ says Miles Messenger, head of energy performance contracting at Bouygues E&S.

Fortunately, the solar farm meant other options could be considered. ‘ It allowed us to use other forms of electric heating, which would have been prohibitively expensive to operate otherwise,’ says Messenger.

Bouygues E&S eventually selected 1.5MW electrode boilers (effectively, large immersion heaters) as the back-up heat source. ‘They were proven to be cost-effective and a similar size to a conventional boiler,’ says Messenger.

Swapping from fossil to electrode also avoided the costs and environmental hazards of stored fuel on site, he adds.

To help build a more detailed picture of heat demand in the village, Bouygues E&S installed heat meters in five archetype properties. ‘There’s a big range of property types in the village, so we picked a typical example of each and put in a heat meter,’ says Troup.

Data from the meters was combined with Energy Performance Certificate data, fuel consumption figures from a few residents self-reporting, and SAP data from 50 homes managed by a local housing association. The team also used data from the Energy Demand Research Project carried out before the smart meter rollout to test consumers’ responses to different information about their energy use. The data was used as a proxy to get an annual demand profile for a typical property type. ‘We had to use a real blend of data sources to get to an approximation of heat use in the village,’ Troup explains.

Hybrid heat pumps

While work to establish the village’s heat demand was undertaken, the team also had to confirm that the field owned by the council had the ability to supply sufficient heat.

Originally, the plan was for 267 boreholes, but thermal testing revealed that this density would have reduced the productivity of the GSHPs significantly because of the amount of heat that would have been extracted by that many ground-loop arrays.

To gauge heat demand, meters were installed in properties representative of the range of building types in Swaffham Prior

To sustain the temperature in the ground – and thereby allow the heat pumps to work more efficiently – Bouygues E&S looked at installing additional air source heat pumps (ASHPs). Iterative modelling established that a 3:1 ratio of GSHP to ASHP was optimal (two 0.75MW GSHPs and one 0.5MW ASHP).

‘The strategy is harnessing the benefits of both technologies,’ says Miles Messenger, head of energy performance contracting at Bouygues E&S. ‘There’s a benefit to using ASHP in the summer, as the warmer air gives rise to a higher coefficient of performance. This also gives the GSHPs’ ground loops a chance to replenish, ready for the next heating season.’ The seasonal replenishment results in a lower thermal degradation rate of the ground loop array, so fewer ground loops are needed – they’re reduced by more than 50% – to meet the long-term demand, Messenger adds.

One of the key challenges of the project was ensuring compatibility with a diverse range of dwellings. The heat network is designed to supply heat at around 72°C, in line with that generated by oil-fired central heating.

Originally, the plan was for 267 boreholes, but thermal testing revealed that this density would have reduced the productivity of the ground source heat pumps significantly

‘The reason this is important is that many older homes, unless retrofitted to high energy efficiency which can be costly, cannot take individual low temperature ASHPs and get the level of warmth and comfort they would like,’ says Councillor Lorna Dupré, Cambridgeshire County Council’s environment and green investment committee chair.

The high temperature will enable residents to dispense with conventional oil-fired boilers and connect to the network through a heat interface unit, without having to upgrade radiators or insulation.

Minimal alteration to the tertiary systems is required, says Messenger. ‘We have options for all common types of domestic system; however, we do need to convert heating systems from gravity-fed to mains pressure.’

The main and unavoidable disruption for occupants is associated with the heat network connections, which require the installation of trenched heat pipework from the property boundary to the building.

OPTIMISING THE HEAT PUMPS

The ASHPs will act as lead from mid-April to early October. They will be used all year round, but make a comparatively small contribution in winter. Switchover to GSHP is based on the ‘real time COP’, driven by the air temperature (ASHP COP) and glycol temperature (GSHP COP). The mode of operation will shift depending on these variables, though it will also be influenced by the RHI tariff and solar PV availability. In general:

Winter: The GSHP will act as lead and the ASHP will act to meet peak loads only.

Shoulder: Either will act as lead, depending on outside air temperature and ground loop temperature, as well as tariff optimisation.

Summer: ASHP will act as lead and GSHP will act to meet peak loads only (unlikely to be required).

As conventional heat pump technology is unable to achieve 72°C efficiently, Bouygues E&S selected heat pumps with ammonia as the refrigerant. This is able to generate higher temperatures while maintaining a reasonably good COP – but there is a downside.

‘The corrosive and hazardous nature of this refrigerant led to significant mitigations in design,’ says Messenger. ‘These include compartmentalisation of the energy centre spaces, emergency extraction ventilation, and leak-detection systems, which had to comply with the Dangerous Substances and Explosive Atmospheres Regulations and the EU ATEX directive.’

The scheme will be linked to a private electricity network connected to a 28MW (AC)/39MW (DC) solar farm owned by CCC. It was decided that both projects would connect to the same distribution network substation. ‘A shared connection would allow electricity to flow “behind the meter”, enabling CCC to self-supply renewable electricity directly to itself,’ says Messenger.

‘By combining the solar farm with the energy centre, we were able to rationalise our network connection costs,’ he adds. ‘This also provides an advantage in managing our export and import to and from the network.’

The electricity generated by the solar farm that is consumed by the energy centre would have otherwise been sold via a wholesale export agreement. The ‘export’ unit rate would be approximately a third of the cost of peak retail ‘import’ unit rate. Thanks to the comparatively large scale of the solar farm, coupled with 4x50m3 thermal stores, Bouygues E&S’s models predict that the vast majority of electricity consumed by the energy centre will be sourced from the solar farm.

The thermal stores are to be used to meet short-term peaks in demand, and will enable the system to optimise tariffs. Generally, they will be charged during the day – when electricity is available via the solar PV array – to provide heat the following evening.

‘Their inclusion, coupled with the hydronic design of the scheme, allows us to deliver a larger capacity of heat into the network for a short duration than the total capacity of the heat pumps – in this sense, the thermal stores act as a capacitor,’ says Messenger, who adds that they can also supply several hours’ heat into the network in the event of unplanned maintenance. Further back-up comes from an electrode boiler, made feasible by access to the solar farm’s cheap electricity (see panel, ‘Back-up heating’ on page 21).

Heat-supply agreements

Avieco engaged with the community over the terms of the Heat Supply Agreement. ‘It is another utility, but the contracts are much longer-term,’ says Troup. Consumer protection is expected to be provided by Ofgem, which is the regulator for heat networks.

To ensure residents don’t pay a premium for their community-supplied heat, the tariff has been linked to the price of heating oil.

‘The other key issue is that joining the community heat project costs nothing if you sign up before the construction is finished – this means everyone, independent of wealth, can join,’ says Dupré.

The project capital costs are £11.9m, which are being funded by a £2.9m grant from the Heat Network Investment Project and capital borrowing by the council.

The cost over the life of the project will be covered by heat charges and income from the Renewable Heat Incentive.

Another challenge was obtaining permission to run pipework under a public highway. No statutory regimes allow this in practice, but CCC found alternative legislative powers that enabled it to access the highway.

The energy centre is 500 metres from the village. The field with the ground arrays can no longer be ploughed but instead will become a wildflower to boost biodiversity

The primary network – being installed by Pinnacle Power – is racing to go live by spring 2022, in time to apply for the RHI grant.

There will be a gradual ramping of connections over the first five years, with a target of around 100 properties in the first 12 months. ‘We aim to deliver around 4GWh/annum within the next five years, which is around 75% of dwellings,’ says Messenger.

When up and running, England’s first rural village heat network is projected to save more than 47,000 tonnes of carbon annually, and could pave the way for similar schemes.

‘It’s not surprising that there are many others interested in replicating the scheme,’ says Dupré. ‘This is a historic village with many challenges including listed buildings, private and narrow roads. We could not have chosen a more difficult village to retrofit – if it can be done here, it can be done anywhere.’ CJ