The airtightness of new-build homes can now be tested using either the blower door or low-pressure pulse technique

A substantial revision of TM23 Testing buildings for air leakage was published in January 2022, prompted by two important changes introduced in the update to Building Regulations in December 2021, which come into force on 15 June 2022.

The Approved Documents now refer to CIBSE TM23, rather than the Air Tightness Testing & Measurement Association (ATTMA) standards, as approved methodology for air leakage testing. A revision to TM23 was, therefore, needed to reflect the significant advances and standardisation in the fan pressurisation (‘blower door’) method that have occurred since the original publication of TM23 in 2000.

A second testing method, the low-pressure pulse (LPP, or ‘Pulse’) technique, is now approved by the Department for Levelling Up, Housing and Communities for testing new-build homes, alongside the blower door technique.

These developments are part of a number of recent advances in building performance evaluation, which include the use of smart meters for estimates of heat transfer coefficients1 and the new BS 40101 on in-use building performance evaluation.

‘To improve the design and performance of buildings, it is essential that we carry out much more testing,’ says David Allinson, from the Building Energy Research Group, School of Architecture, Building and Civil Engineering at Loughborough University, who is one of the peer-reviewers of the TM. ‘Measuring air leakage is one important and cost-effective approach. So, it is fantastic to see CIBSE providing updated guidance in this fast-moving and exciting area of research and innovation.’

Testing techniques

The fan pressurisation technique, developed in the 1980s and used throughout the world, uses a fan (or series of fans) to pressurise or depressurise a building; the air leakage rate is derived at a reference pressure, which is 50Pa in the UK.

There are a number of standards available to cover the technique and associated calibration requirements, and a reasonable track record on repeatability of results.

Fan pressurisation equipment typically used in individual dwellings and small buildings for blower door tests

As the building is under (de)pressure conditions, it is possible to carry out leak-finding during the test – for example, using smoke pens. The reference pressure of 50Pa is higher than buildings experience in normal conditions and, as such, the technique is viewed as a ‘stress test’.

Consequently, there has long been interest in developing a test that would be more representative of the pressure conditions usually experienced in buildings. While tracer-gas methods directly measure infiltration, they are specialised and time consuming, and results are heavily affected by conditions at the time. It means tests need to be repeated to give a good representation of building performance.

The LPP technique looks to address this. It works by releasing a short burst of pressurised air (a ‘pulse’) and measuring the pressure response of the building. It derives the air leakage rate using similar principles to the fan pressurisation technique, but over a very short space of time (a few seconds) and a narrower and lower pressure range, with a reference pressure of 4Pa. While still not ‘normal’ conditions, this is much closer to those usually experienced in buildings.

The LPP method is patented by the University of Nottingham, which has developed the Pulse technology in partnership with manufacturer Build Test Solutions (BTS). It is recent – with the main field trials carried out in 2016-18 – and, overall, the results were obtained from a relatively small sample of homes, and under relatively narrow testing conditions.

By the nature of R&D, the majority of the reported studies were undertaken with earlier iterations of the system (that is, testing equipment and/or software). While Building Regulations allow the technique for all new homes, TM23 recommends caution when using it on homes targeting very airtight levels, because of more limited evidence in that range.

Because of the lack of standards covering the LPP procedure and equipment calibration, TM23 recommends that, for regulatory purposes, calibration should be done against a ‘master’ device, and not by the tester or their organisation, to provide a degree of independence. This is an important area, where requirements may evolve as the technique matures to become increasingly similar to those applied to the fan pressurisation method. See panel, ‘TM23 procedure recommendations’.

a multi-fan installation that can be used for large buildings (courtesy of BSRIA)

Use in SAP

As well as being a performance metric in itself, the air leakage test result is used in the UK in energy calculations, including Building Regulations Part L. For homes, this is done using the ‘divide by 20 rule’, to derive the infiltration rate from the air permeability at 50Pa.

The rule was initially based on air change rate, not air permeability, so using it with air permeability assumes a volume-to-envelope area ratio of 1. This could be addressed relatively simply in SAP by taking account of the building envelope and volume, rather than using a blanket ratio.

The reliability of the rule has been questioned in academic research for a number of years, however, and it is a source of uncertainty for energy use and infiltration, and, in turn, ventilation.

Figure 2: Pulse 2.0 system – compressor on the left-hand side, air receiver in the middle, controller on the right-hand side (courtesy of Build Test Solutions)

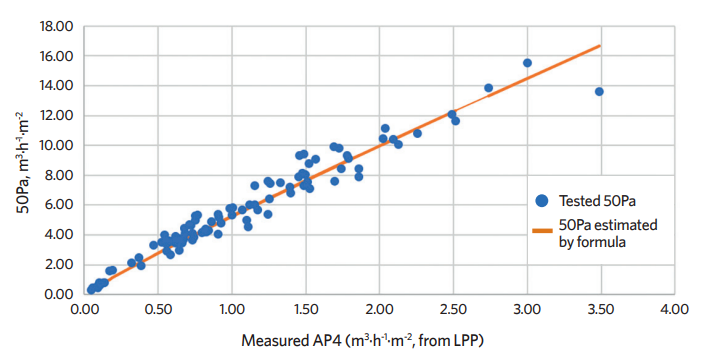

Following the government’s approval of the LPP, a conversion formula has been developed by BRE with BTS, so that air permeability results obtained at 4Pa can be ‘converted’ into estimated results at 50Pa for use in SAP. The formula is based on analysis and correlation of a large number (293,000) of blower door tests, and a more limited number of tests obtained at both pressures on the same buildings. While the conversion is understood to be within the margin of error of each testing method, it introduces another level of uncertainty into SAP calculations, in addition to the ‘divide by 20’ rule. It is hoped that both these aspects will be examined for SAP11 and the Future Homes Standard.

As the industry will now be communicating air leakage values at two different reference pressures, it will be important when reporting results to be clear about the reference pressure to which they relate, and whether they were obtained directly from a test at that pressure, or by correlation from a test at the other pressure. For example, tested air permeability at 50Pa obtained by fan pressurisation test, or estimated air permeability at 50Pa obtained from a test result at 4Pa and the SAP conversion formula (the latter is not actually a test result at 50Pa).

What next, and what can you do?

An important source of uncertainty is not the techniques themselves, but what happens on the ground – for instance, measurements, building preparation, departure from recommendations (whether intentional or not), and so on.

Figure

The Competent Persons Scheme (CPS) can help address this. The TM provides a framework methodology for consistency in testing procedures and how test results are reported, but it does not go to the level of detail of industry resources such as the ATTMA suite

of documents. It is expected that the CPS will revise its resources to align with the new TM, and CIBSE is open to collaborating with CPS.

Martyn Reed, group managing director at Elmhurst Energy, says TM23 offers an opportunity for all airtightness testers to have a say in how tests should be performed. However, he believes the guide is just a starting point: ‘In our view, the speed of publication has meant that some of the detail is lacking, and some of the previous assumptions needed to be tested, but we are delighted with the direction of travel.’

This is an evolving field. TM23 includes a literature review on the current state of evidence, including for method issues such as accuracy, repeatability, and influence of outside conditions. This has informed the recommendations and points to areas where project teams may wish to go beyond minimum requirements, or where knowledge and practice may still evolve.

TM23 PROCEDURE RECOMMENDATIONS

TM23 is based on ISO 9972:2015 and builds on best practice. As such, most recommendations will be familiar to testers. Points to note include:

- Record wind conditions during the test; take photographic evidence of building preparation and the building’s state of completeness

- Trickle vents can be closed, but should not be sealed

- With blower door tests, carrying out both pressurisation and depressurisation is not required for regulatory purposes, but is recommended whenever possible. The result is then the average of both. This provides a more complete picture of fabric behaviour, and can reduce the risk of errors because of outside wind, especially gusts. It is required when testing for Passivhaus.

Testers and project teams are encouraged to contribute to the growing body of knowledge by sharing testing data with CIBSE, academia and the industry, especially in the following areas: feedback on TM procedures; test results obtained on the same building under both techniques; test results (under either technique) obtained on buildings where tracer-gas methods to assess infiltration rate are also used.

- CIBSE TM23 is free to members of the Competent Person Schemes, ATTMA and Elmhurst Energy Airtightness. Contact your scheme to obtain the download code. Watch the CIBSE TM23 launch video at bit.ly/CJApr22JG1

References:

- Smart meter-enabled thermal efficiency ratings (SMETER) technologies project: technical evaluation, 27 January 2022, BEIS bit.ly/CJApr22TM23

DEFINITIONS

Infiltration is used to refer to air movement through the envelope under normal conditions.

Air leakage is used to refer to air movement through the envelope under a pressure differential. It is expressed as air leakage rate at a reference pressure, either as air change rate or air permeability