Electric cars have almost doubled in popularity in the UK over the past year, and sales will continue their steep trajectory as the industry prepares for the phase-out of petrol and diesel vehicles by 2040.

Alternatively fuelled vehicles – of which plug-in hybrid electric vehicles (PHEV) and battery electric vehicles (BEV) make up the vast majority – represented 5.8% of the total market for new cars in May, a record for the UK.1

The government is aiming to ensure that almost every car and van on UK roads will be zero-emission by 2050. This policy ambition, shared by many nations and automotive manufacturers, is aimed at creating cleaner air in our cities.

Roadside nitrogen dioxide (NO2) is a public health problem that needs addressing urgently, and more electric vehicles (EVs) are seen as a key way of tackling this. Through tax incentives, grants and funding, the UK government hopes to stimulate interest in EVs, sales of which are now increasing faster than their combustion-engine counterparts.

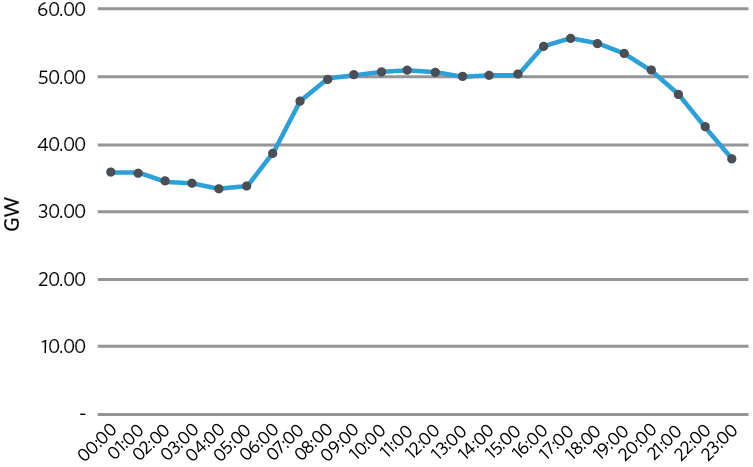

Figure 1: Typical UK electricity consumption over 24 hours in December 2017

Rapid growth in electric vehicle sales will require vehicle-charging infrastructure to match. We will have to change the way we refuel our vehicles, and service stations will no longer be the only place to do this.

Whether at work, rest or play, we spend a large proportion of our life in buildings: a couple of hours shopping; nine hours at our place of work; or 12 hours relaxing at home. Our vehicles can be charged at all these locations.

If electric vehicles are not charged smartly, peak demand could be as much as 8GW higher in 2030

As a result, significant charging infrastructure will be needed in various building sectors. These charging-point capacities are likely to lead to large load increases in buildings if we do not design appropriate infrastructure. With creative design, we can mitigate these increases to reduce demand on the UK electrical infrastructure.

Through load management and by considering the time of day that we charge our vehicles – as well as the potential use of battery storage technology – significant amounts of energy are already available within the UK grid, for seven hours at night.

Even in December, when the UK load peaks at around 56GW, the electrical demand stays stable from midnight to 7am, at around 35GW. If building services engineers grasp the challenge, this existing energy generation could power a large proportion of the 323 billion miles travelled on UK roads every year. As the National Grid has said: ‘If electric vehicles are not charged smartly, to avoid peaks and troughs in power demand – such as when people return home between 5pm and 6pm –peak demand could be as much as 8GW higher in 2030.’

Plug-in hybrid v battery electric vehicles

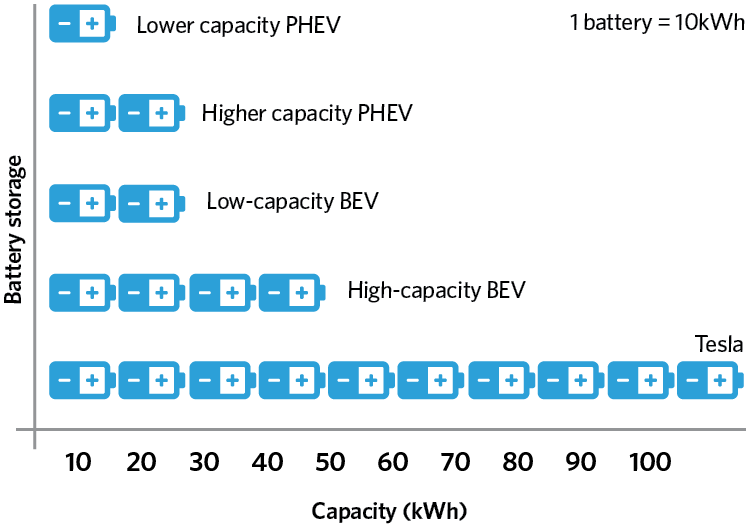

Space on board PHEVs is limited because of the need for a combustion engine, so the battery storage capacity is typically around 7kWh to 10kWh. On some larger vehicles, such as SUVs, battery storage can increase to 17.4kWh. Typical BEV storage capacity is between 14.5kWh and 36kWh. These figures ignore Tesla’s range, which would skew the maximum onboard battery storage to 100kWh. (See Figure 2.)

Figure 2: Storage capacities for PHEV, BEV and Tesla batteries

PHEVs generally have single-phase AC charging connections, while BEVs tend to have both single-phase AC and rapid-charge DC connections. Only some BEVs can take a 3-phase AC charging connection. When the vast majority of PHEVs and BEVs are connected to a 3-phase charging point, they will only draw a single-phase load. If all the buildings connected to a local utility network had 3-phase AC charging points, they could create significant imbalances in the local network. So it would be better to install single phase AC or large DC charging points within buildings.

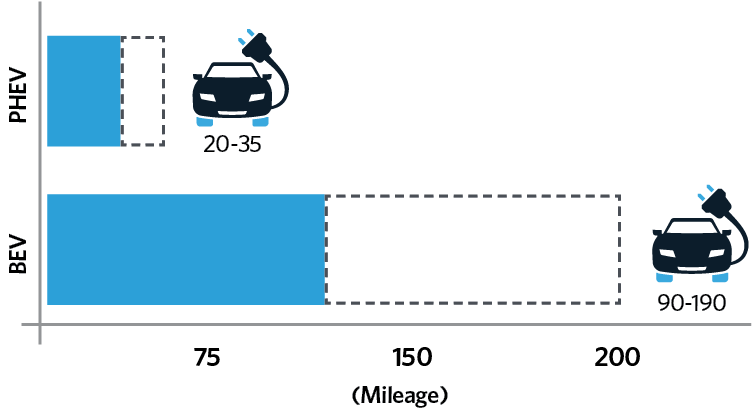

A PHEV’s range on pure electric drive is between 20 and 35 miles, depending on the size of the vehicle and battery storage. The range of a BEV vehicle is between 90 and 190 miles. (See Figure 3.) A Nissan Leaf has a 155-mile version, while Tesla has a range-busting Model S that is capable of driving between 250 and 325 miles without being charged.

Figure 3: Typical range of a PHEV and BEV

Charging points

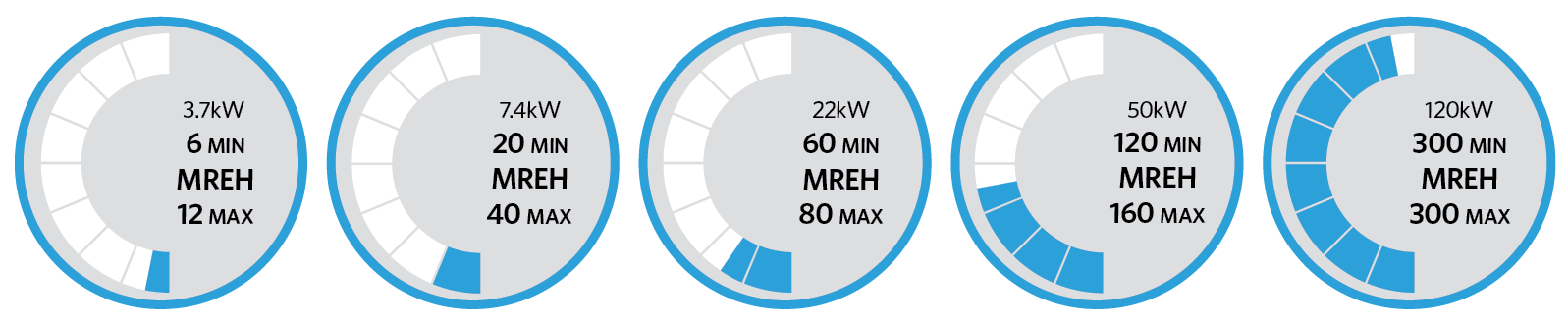

As engineers, we should try not to use the term kW when we talk about charging points; instead, we should describe each charging point as a mile of range every hour (MREH) connected.

Figure 4, on page 30, is a diagram of typical range for each kW charging point. The variance is generally down to the weight and aerodynamics of the vehicle. Over a typical nine-hour period at work, a 3.7kW charging point could give you between 54 and 108 miles; at home, it would give 72 to 144 miles.

The current trend is to install a small number of charging points, that are as large as possible, within car parks. While the impact of a few vehicles charging may not be significant on the overall load of a building at the moment, this may not be the case in future.

Figure 4: Range, in miles of range every hour (MREH) connected, for charging points from 3.7kW to 120kW

The panel ‘Impact of EV charging on workplace electricity loads’ (page 30) shows that the existing electrical infrastructure for most places of work will not be big enough to cope with a large number of electric vehicles being connected to them. It is imperative that discussions are held with developers, occupiers and building owners to ensure that we do not unnecessarily increase total loads by specifying and installing too large a vehicle connection point (see Figure 5).

Mitigation of load

There are several options available to reduce the impact that EV-charging points have on the overall load on buildings. One of the main methods is to install a load-management system. This works by regulating the power to each charging point.

There are different ways in which this can be done. One is to offer a fixed load from the load-management distribution board; another is to regulate the charging rate to each point. Preferential treatment could be given to customers, so that – for a price premium – they would secure the higher charge rates.

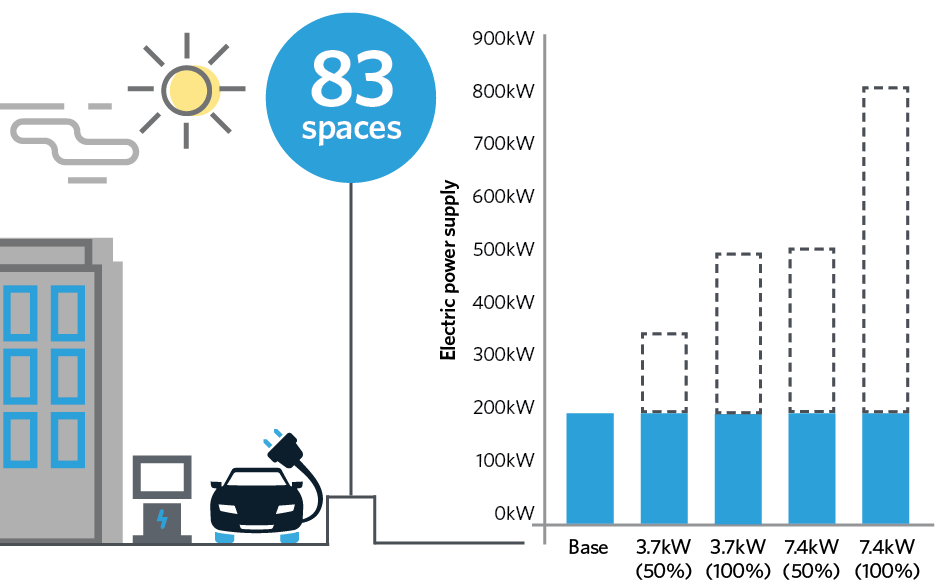

Figure 5: Increase over base load in buildings when 3.7kW and 7.4kW charging is added for 100% and 50% of car parking spaces

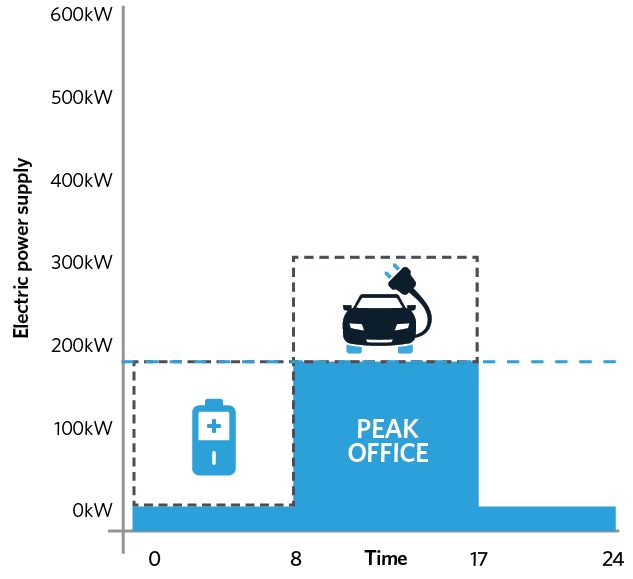

To try to reduce further the overall impact that electric vehicles have on buildings, battery storage could be installed within properties. This would enable night-time electricity to charge batteries, so that EVs could draw power when they need a charge as rapidly as possible, without large increases in building infrastructure or incoming electrical supplies (see Figure 6).

In the work scenario, load management and battery storage may make it possible to serve 33 spaces while working within the current building incoming supply.

Figure 6: How battery storage could be used to cover extra charging load

Moving to EVs will require a shift in the way we think about how we refuel vehicles. Most probably, we will be plugging our vehicles in overnight and charging them when we arrive at work. Charging facilities at leisure destinations may not prove as popular and necessary, as the vast majority of charging would be done where we are stationary for the longest.

All of the above assumes that, by 2040, we will still own cars; autonomous vehicle technology may change our approach to vehicle ownership and, hence, car charging. This emphasises the importance of planning our future, by managing typical building loads that do not account for vehicle charging currently.

Load management and battery storage technology are vital to ensuring that buildings can cope with the introduction of the charging of electric vehicles.

Impact of EV charging on workplace electricity loads

If each car parking space within an office building or place of work had a 3.7kW single phase AC circuit, the maximum number of parking spaces in a typical 2,500m2 office could be about 83, which would give a load of 310kW.

At 80W/m2, the office load would be about 200kW. Allowing all vehicles to charge could result in a 250% increase in incoming electrical supply to a site – for example, 500kW instead of 200kW.

If the number of parking spaces was reduced by half – or half the number of spaces were connected to a charging point – the load increase would be around 175%: 355kW instead of 200kW.

If a 7.4kW load was allowed for each electric vehicle (EV) car parking bay, the loads above would be doubled – so the total load for the 2,500m2 office could be about 614kW or 814kW, depending on the number of parking spaces. Without EV charging points, a 200kW supply would have been OK.

■ Adam Selvey is building services director at engineering and environmental consultancy Ramboll

References

- Car registrations, May 18, Society of Motor Manufacturers and Traders