The falling infection rates of Covid-19 have led to the easing of lockdown restrictions around the world and, with that, an increase in the number of people reoccupying buildings such as offices, factories and schools.

The UK government, for example, revealed a roadmap for emerging from lockdown on 10 May. It stated that people should return to work from 12 May (if it was not possible for them to work from home) and it announced plans to reopen some schools on 1 June.

To ensure that infections don’t rise again as populations remobilise, the government and organisations such as CIBSE, ASHRAE and REHVA are issuing guidance aimed at minimising the risk of people falling ill with Covid-19 in reoccupied buildings.

Current guidance from Public Health England (PHE) states that Covid-19 is assumed to be primarily transmitted through respiratory droplets from coughing and sneezing, which come into contact with others directly or via contaminated surfaces.

Key actions

- Understand the ventilation system

- Run ventilation at higher-volume flowrate

- Avoid recirculation/transfer of air from one room to another unless this is the only way of providing adequately high ventilation to all occupied rooms

- Recirculation of air within a single room where this is complemented by an outdoor air supply is acceptable

- If applicable, thermal wheels should be switched off, but the pressure difference between supply and extract will need to be maintained to minimise any leakage flow from the extract to supply side

The government’s Chief Scientific Advisor, however, has acknowledged that airborne transmission is a route, particularly in poorly ventilated spaces. As a result, organisations including CIBSE, ASHRAE, REHVA and BESA are advising that workplaces boost ventilation so indoor air is sufficiently diluted to eliminate the potential for airborne viral transmission.

In an April briefing note, Coronavirus Covid-19 and HVAC Systems, CIBSE said that dilution of the internal air reduces exposure time to any airborne viral aerosols and lessens the chance of these aerosols settling on surfaces (the virus has been shown to survive for up to 72 hours on some surfaces).

Last month, the Institution published a more detailed document, Covid-19 Ventilation Guidance, aimed at building owners, managers and operators who are reopening non-domestic buildings in a temperate, oceanic climate, as experienced in the UK. It is not aimed at healthcare and hospital buildings, which are covered in guidance by the NHS and PHE.

The document outlines different types of ventilation, to help building managers identify systems in their facilities. It outlines the actions that should be taken to minimise transmission of Covid-19 for each system. Recommended actions are broadly classified under the headings of natural and mechanical ventilation. This article will look at guidance for the latter.

Mechanical ventilation

CIBSE recommends that buildings with mechanical ventilation extend operation times, with nominal ventilation being established two hours before and after building usage time.

In demand-control systems, CO2 setpoints should be set to 400ppm to increase delivery of outside air, says CIBSE, which adds that ventilation should be kept on 24/7, with lower ventilation rates when people are absent. Where there is humidity control, relative humidity should be set above 40%.

Heat-recovery systems should not pose an increased risk if supply and extract streams are completely physically separated, such as twin coil units or plate heat exchangers, although CIBSE recommends an inspection in case there are any leaks that might lead to transfer of air from discharge to intake duct.

For thermal wheels (or rotary heat exchangers), CIBSE says there may be a risk of air leakage and moisture transfer between supply and exhaust air streams.

A higher pressure on the extract side of the thermal wheel can cause air leakage to the supply flow, particularly in poor installations, so CIBSE recommends that the thermal wheel be bypassed. If it can’t be, the rotor should be turned off and the ventilation rates increased as much as reasonably possible.

The heat-recovery equipment should be inspected, says CIBSE, and the pressure difference measured – and, if necessary, corrected by an appropriately trained technician, using dampers or other arrangements. Workers should adopt usual safety procedures when working on thermal wheels.

CIBSE and others recommend stopping central recirculation during the Covid-19 outbreak, by closing dampers via the BMS.

While bypassing recirculation may impact the building’s heating or cooling capacity, CIBSE says ‘it was more important to reduce contamination risk and protect public health than to guarantee thermal comfort’, and recommends relaxing dress codes.

Even if air handling units and recirculation sections had return air filters, it is not a reason to keep recirculation dampers open, as these do not normally filter out particles with viruses effectively because they have standard ISO coarse/ePM10 filter class rather than Hepa efficiencies.

Filters should be changed with systems turned off, and PPE must be worn. Used filters must be disposed of appropriately, in a sealed bag

It warns that Hepa filters should only be used in filter housings designed for Hepa, otherwise there is the possibility of air leaking around the filter, or reducing the rate of supply of fresh air through increased resistance.

If guidance on heat recovery and recirculation is followed, CIBSE says the ductwork system should not be a source of elevated risk of contamination and no changes to normal duct-cleaning procedures should be necessary.

Outdoor air filters are not seen as a high-risk source of Covid-19 particles, so they do not need to be replaced, says CIBSE, which recommends normal maintenance procedures for replacement filters. Clogged filters are not a contamination source, but should be replaced because they reduce supply airflow.

Maintenance staff may be at risk from changing filters (especially extract), says CIBSE. Filters should be changed with systems turned off, and PPE must be worn. Used filters must be disposed of appropriately, in a sealed bag.

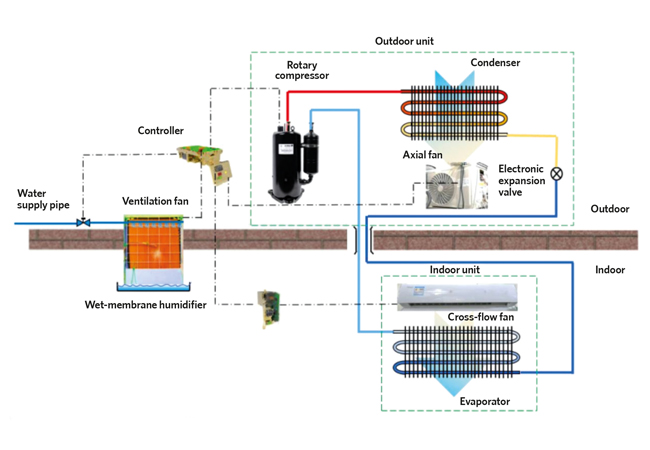

‘Split’ air-conditioning systems do not normally bring outside air into a room and, without a dedicated source of outside air supply, there is a risk they could recirculate and spread airborne viral particles, says CIBSE. It recommends having a source of outside air – either natural or mechanical ventilation – when these units are in operation.

For fan coil units, CIBSE says that, if there is little outside air ventilation, the action of a fan coil unit could spread airborne viral particles and should be turned off. However, with a good source of outdoor air supply, fan coil units may help mix the air and ensure dilution of any airborne virus everywhere.

Checking chillers after lockdown

Property services company Cushman & Wakefeld has published a guide to reopening buildings, which includes a checklist for assessing the physical condition of equipment and services. This has advice for chillers.

Air-cooled chillers

- Clean condenser coils and check for leaks and corrosion

- Check controls and safety circuits for proper operation

- Condenser fans should be cleaned; bearings need to be checked for wear, and lubricated; belts and couplings need to be examined, and tightness checked and adjusted

- The electrical disconnect and contactor needs to be inspected for tightness and no pitting

- Compressor oil should be tested for acid

- Check oil filter and change if needed

- Check piping and compressor for any signs of leaks and test refrigerant pressures

- Run a general system test to check for unusual noises, odours, and measure supply/return temperatures and system pressures as needed.

Water-cooled chillers

- Check quality of condenser and chilled water chemical levels

- Check condition of condenser water tubes, and clean if needed

- Check refrigerant levels

- Check refrigerant purge unit

- Check oil heater

- Check oil levels

- Inspect motors and starters

- Run a general system test to check for unusual noises, odours, and measure supply/return temperatures on both condenser and chilled water and system pressures as needed

Active chilled beams can operate normally, says CIBSE, as they form part of a ventilation system. Passive chilled beams do not bring outside air into the room, and will need a good supply of outdoor air to enable them to operate without risking airborne transmission of Covid-19.

CIBSE says room-air cleaners can be effective if they have Hepa filter efficiency and a substantial amount of room air passing through them. Devices that use electrostatic filtration principles can also work well.

CIBSE says air cleaners should be located in the centre of the room, away from ‘stagnant’ areas – but the formation of any stagnant zones should be avoided. UV cleaning equipment for room-air treatment can also kill bacteria and inactivate viruses, but is usually only suitable for healthcare facilities.

Finally, CIBSE guidance states that, where there is no obvious ventilation strategy in a space, occupants should be discouraged from using the space. If the space is used transiently – for example, stairwells and corridors – then CIBSE recommends more robust cleaning regimes.