Patterns of church use can vary sharply from parish to parish. A flourishing church in a growing community may have a daily service, while a remote chapel with an ageing congregation may only have a service on Sundays.

People still need to be warm and comfortable, though – no matter how full the pews. As churches tend to be uninsulated, this means dioceses have to spend thousands every year to keep their parishioners warm; they also have to keep the heating on between services, to minimise the risk of surface and interstitial condensation on the building fabric.

To calculate the most efficient heating levels in a church, it is important to consider the minimum temperature to which a church can be heated without risking condensation, and what heating levels are required to stop a congregation focusing on keeping warm.

Construction of churches is extremely varied. Materials may be non-uniform, and traditional ones have little or no fabric thermal insulation

The study that informed the guidance considers the energy use of heating a typical church in winter, and at the costs of various heating strategies. It encompasses churches with between one and seven services a week, and assumes controlling minimum temperatures between 8°C and 12°C.

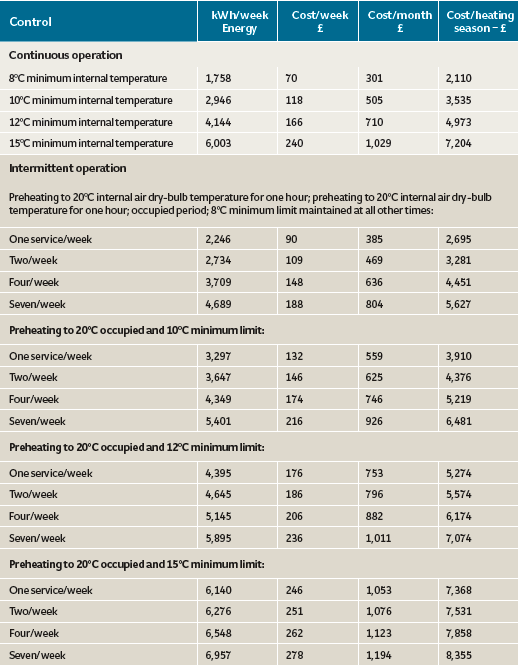

Changing minimum internal temperatures can have a dramatic effect on heating costs. By reducing the temperature from 12°C to 8°C, for example, a typical church could save more than £4,500 during the heating season (See Table 1, Energy and heating cost guide). A reduction to 8°C should be considered if the church is unused between services.

This underlying study was based on the winter climate in the East Midlands, but may be applied to other UK areas with a different climate. Other assumptions can be seen in the panel ‘Study assumptions’.

The construction of churches is extremely varied, with alterations and extensions sometimes carried out centuries after the building was first put up.

Materials may also be non-uniform, and traditional churches have little or no fabric thermal insulation.

There are many factors that contribute to heating requirements in a church, including: building fabric type; window areas and type; the provision of doors and porches; prevailing wind directions; and ventilation infiltration rates, including the impact of cold draughts.

The thermal mass of the construction will have to be taken into account, as will: transmittance and admittance; specific heat; space temperature gradient; distribution losses from thermally insulated main services; heating plant response; and maintained efficiency.

Allowances should also be made for cold air infiltration and adventitious solar, occupancy, power and lighting gains. (For more on calculating thermal performance of historic buildings see ‘Cambridge First’, CIBSE Journal, June 2016.)

Study assumptions

Winter space-heating loads may be established using local winter weather conditions prevailing at -3°C typical external ambient design air temperature, in accordance with CIBSE Guide recommendations for heavyweight buildings with overload capacity, using computer model and dynamic simulation.

Seasonal variation in space-heating loads may be based on CIBSE climate frequency data or programmed data throughout a typical winter of 30 weeks’ (seven months’) duration. Heating has been assumed to be required from October to April, with simultaneous operation of all control zones.

Dynamic simulation will normally include one to two weeks of design weather for space-heating and system frost protection when external ambient dry-bulb temperatures may be at or below design.

Heating plant and system outputs should be determined as accurately as possible, in accordance with agreed project design parameters. Heat outputs may vary, typically in the range 100kW to 300kW.

Church heating systems are typically designed to raise the temperature during preheating to 20°C immediately before occupancy, and maintain that temperature for approximately one hour, depending on the type of service or event. Boiler and system heat output must be sufficient to ensure satisfactory economic preheating of the church. Churches and associated facilities are often used on a highly intermittent basis.

To protect the building fabric from surface and interstitial condensation, minimum limit temperature can be maintained in the 8°C to 12°C range. Higher internal surfaces should be considered to protect the building fabric against condensation in very well-attended churches.

The study

The study is based on a church of 728m2 treated floor area and 7,220m3 heated space volume. Design preheating and seasonal heating loads were calculated using an IES model programme, CIBSE loads and dynamic simulation. Boiler output was determined from space design preheating load plus 2.5% mains loss and 7.5% margin.

The study is based upon the use of a conventional new, high-efficiency, natural-gas-fired, condensing low-pressure hot water (LPHW) modular heating boiler and system, rated at 200kW nominal total heat output using fan convector heat emitters. Associated electrical energy use is relatively small and has been omitted.

Importance of controls

Choice of control method has a significant impact on the gas utility bill. Building energy management systems’ (BEMS’) heating control normally includes: optimum start; external temperature compensation; variable heating flow rate; and burner modulation turndown, to promote condensing operation and thermal efficiencies throughout the range of seasonal heating loads, with facility for zone and external remote control. Basic time-clock and thermostatic control may suit smaller projects. Zone control is useful when a building layout may be suitable for division into separate areas, to maintain efficient operation of heating in all zones.

The heating energy cost guide is subject to variation in energy usage during prolonged mild or severe winter weather, above or below the average monthly temperatures. Actual heating energy use can be expected to vary, on average, by up to ± 10% of guide figures when using a 200kW boiler.

Calculated figures have been extracted from a current church project in the East Midlands. Figures will vary on other projects with similar overall heat output but different constructions. Interpolation or extrapolation of tabulated figures can be applied with caution to other projects with larger or smaller heat outputs and similar general design parameters and control.

Continuous heating operation is shown in the table for comparative purposes only, and cannot be recommended unless the available fuel budget of the church determines otherwise. While maintaining an 8°C continuous minimum limit temperature will provide building-fabric protection against surface or interstitial condensation, it is well below a recommended air dry-bulb temperature of 20°C in churches.

Heating energy cost guide – this includes the cost for continuous and intermittent heating operation. Costs are based on typical 4p/kWh current overall natural gas tariff charge, which can be adjusted for other tariffs, and have been rounded up or down to the nearest pound to assist comparison

Summary

Intermittent heating operation with minimum limit control is recommended to provide satisfactory comfort during occupation with optimum use of energy.

The cost of intermittently heating the above church once a week for a service, function or event of one-hour duration at 20°C occupied air dry-bulb temperature – while maintaining minimum limit temperature of 8°C at all other times – is £2,695 from the table over the course of a heating season.

For two, four and seven services a week, the costs are £3,281, £4,451 and £5,627 respectively. The range of these costs is from £2,695 to £5,627 – a difference of £2,932 or 109% of minimum cost.

If intermittent heating to 20°C air dry-bulb temperature and 15°C minimum limit was maintained, costs would range from £7,368 to £8,355 – a difference of £987 or 13% of minimum cost.

Where the number of daily visitors to the church between services or events is significant, a 12°C minimum limit temperature would be desirable during the winter, but the energy and fuel use is appreciably higher than maintaining 8°C minimum temperature. To reduce energy, maintain the 12°C minimum temperature during the day for visitors, but allow the temperature to decay to 8°C control minimum overnight and when the church has no – or very few – visitors.

Choosing a lower air dry-bulb temperature of 18°C reduces energy and fuel use, as does operating fewer heating zones, or operating heating for less than 30 weeks a year if the prevailing winter weather permits.

James Sheehan is a director of James Sheehan Consulting Engineers