Fire dampers, smoke control dampers, and natural smoke and heat exhaust ventilators (NSHEVs) play a vital role in life safety – either by helping to contain fire and smoke within defined compartments, or by extracting smoke to keep escape routes clear and usable during a fire. This article examines some key considerations in the successful application of these systems.

In a building fire, smoke presents the most immediate threat to life, as it can rapidly spread, obscure escape routes, and cause fatalities within minutes. To reduce this risk, fire compartmentation divides a building into fire-resistant zones that help contain fire and smoke, protect structural integrity, and provide occupants with time to be evacuated from the building.

Building regulations recognise the importance of both containing and extracting smoke, with smoke control dampers and NSHEVs playing distinct but complementary roles in these strategies.

Where ductwork penetrates compartment walls or floors, fire dampers are used in combination with penetration seals – fire-resistant materials that restore the fire-stopping performance of the barrier. During normal operation, fire dampers allow airflow, but they are designed to close automatically when exposed to heat, helping to contain fire within its compartment of origin. Closure is triggered either by a mechanical fusible link or by a motorised actuator with an integral thermal release. Motorised dampers, such as the example shown in Figure 1, can respond to a control signal or a loss of power, whereas mechanical dampers rely solely on heat activation.

Figure 1: An example of a CE-marked ‘ES classified’ fire damper suitable for duct mounting that can be used in concrete/masonry floors/walls, dry walls, and composite wall systems (Source: Swegon)

Smoke control dampers may be integrated into general ventilation systems or dedicated smoke extraction systems. Their primary function is to help establish a controlled path from the fire compartment to the open air, enabling smoke to be safely removed from the building during a fire.

A smoke control damper – such as the example shown in Figure 2 – is designed to regulate the movement of smoke and hot gases from the fire zone to a designated exhaust point, in line with the programmed cause-and-effect strategy within the smoke control system. These dampers respond to signals from the system controller, actuating to an open or closed position typically within 60 seconds, helping to maintain clear escape routes and support safe evacuation.

Figure 2: An example of a CE-marked ‘EIS classified’ multi-blade smoke control damper for use in multi- and single-compartment automatic activation smoke control systems (Source: Swegon)

Smoke control systems are categorised as either automatic activation (AA) or manual activation (MA). AA systems respond automatically to a fire or smoke signal without the need for human input, whereas MA systems require manual intervention to trigger a predefined sequence of automatic actions.

Dampers certified for use in MA systems are generally more robust and also meet AA requirements, but this added durability comes with increased weight, complexity and cost. In the UK, particularly for residential and commercial buildings, AA systems are more commonly specified because of their simplicity and reliability.

A further distinction is made between single-compartment and multi-compartment dampers. Multi-compartment dampers are tested to more stringent criteria, including higher temperature exposure and longer fire durations, making them suitable for use across multiple fire zones. Single-compartment dampers, by contrast, are typically tested only to 600°C and are restricted to the terminal section of a ductwork run.

Given the scale and complexity of modern basement and mixed-use developments, multi-compartment dampers have become the industry standard. Multi-compartment dampers can be used in single-compartment applications, whereas the reverse is not permitted.

Smoke control dampers should not be confused with fire dampers, or with ambiguous terms such as ‘fire smoke dampers’, which have no recognised status under current standards. Unlike fire dampers, which fail-safe to a closed position using thermal links or probes, smoke control dampers must be actively controlled. They are driven to an open or closed position in accordance with a defined cause-and-effect strategy and must not rely on passive mechanisms.

These dampers use powered actuators to maintain or change position, and are required to respond within 60 seconds of activation as part of an automated smoke control sequence. To meet compliance requirements, smoke control dampers must be tested to at least 10,000 actuation cycles, while a more demanding 20,000-cycle test confirms suitability for modulating applications – such as systems that combine ventilation and smoke extraction and require air balancing in day-to-day use.

If dampers in a smoke control system operate while fans are running, the aerodynamic load must be replicated during cycle-testing. However, if fans only start after dampers have moved into position, testing can be done without this load. This underscores the need to consider damper operation as part of life-cycle planning at the design stage.

Smoke control dampers, fire dampers and NSHEVs are categorised as life safety systems under the Construction Products Regulation (CPR). As such, they fall under the CPR Assessment and Verification of Constancy of Performance (AVCP) System 1, which requires both independent type testing and ongoing factory audits by a notified body.

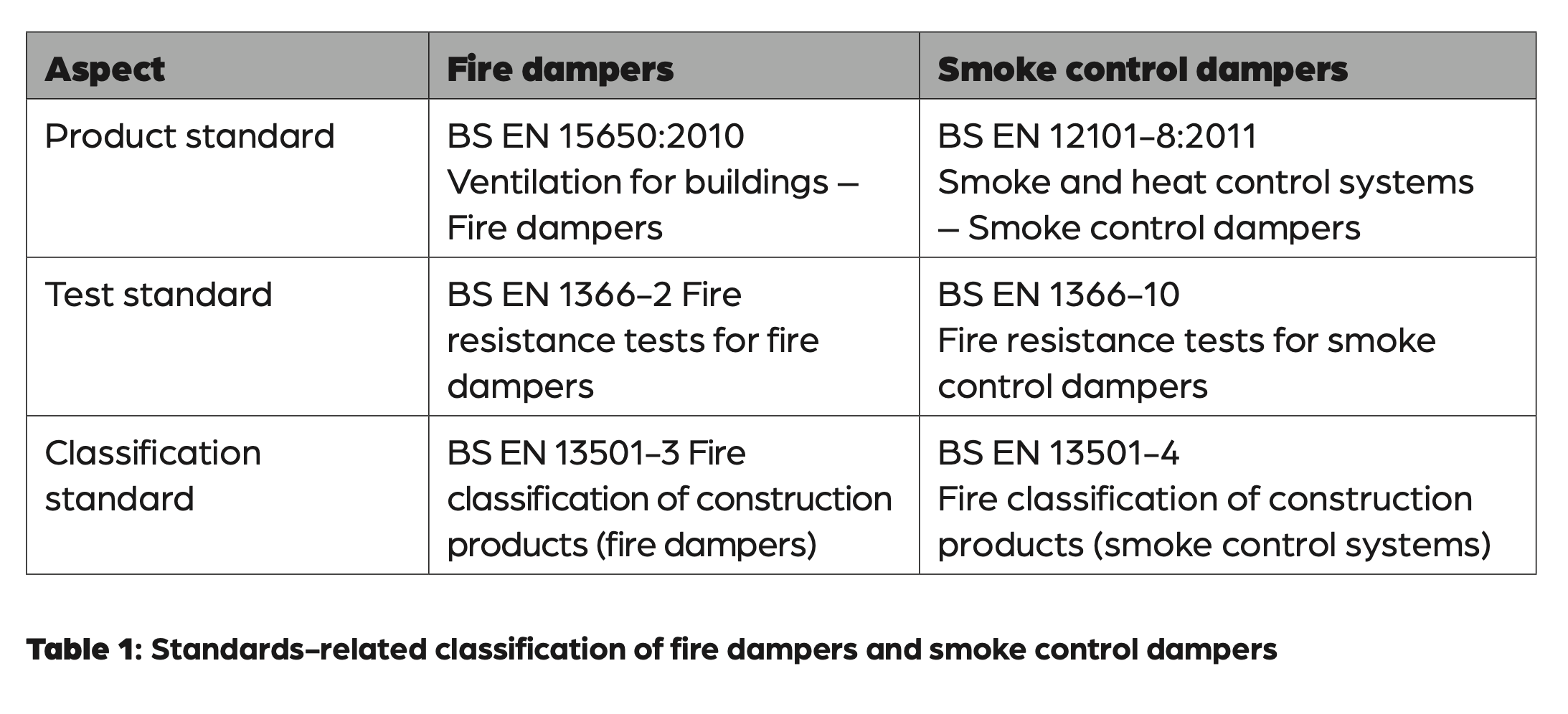

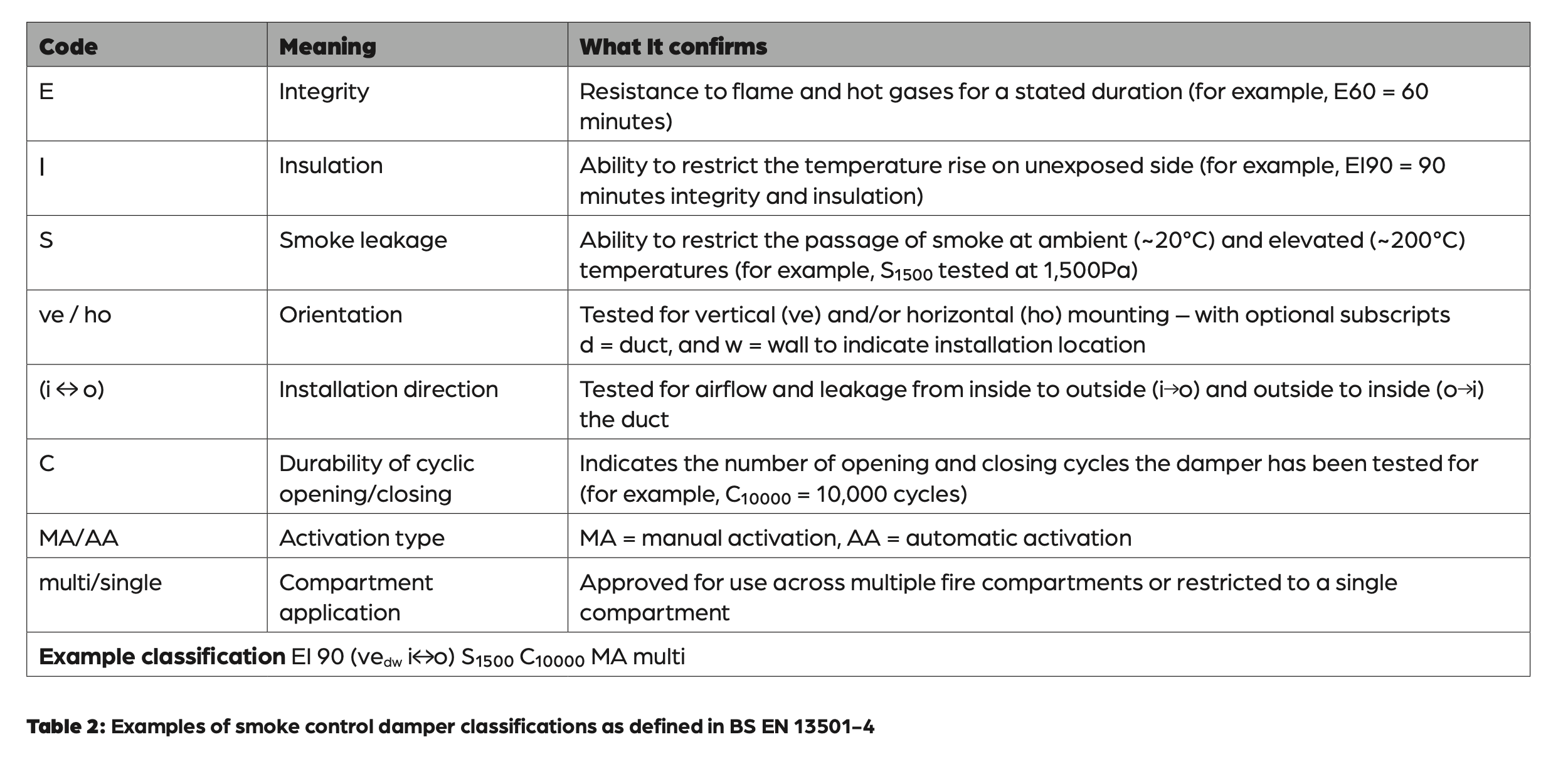

Since 2013, it has been a UK requirement for fire and smoke control dampers to carry CE marking to demonstrate compliance with standards, as outlined in Table 1, and confirms performance in three key areas: integrity (E), insulation (I), and smoke leakage (S).

The classification required will vary depending on the application and can incorporate a number of parameters – examples for a smoke damper are given in Table 2. CE marking remains dominant in the UK, especially in the construction products sector, and UKCA marking remains aligned to EU standards, but future divergence could present a challenge for designers and manufacturers.

Controlling damper operation during a fire event is fundamental to effective smoke control and compartmentation. Historically, simple fusible link systems were widely used, relying on heat activation alone to close dampers. However, modern codes increasingly require active control of dampers, particularly where means of escape must be protected. To achieve this, two broad approaches to damper control are available: hardwired and addressable systems.

In a traditional hardwired system, each damper is connected directly to the control panel using dedicated cables for both power and monitoring. While this method is straightforward, it becomes impractical as the number of dampers increases. The need for extensive cable containment, combined with voltage drop limitations restricting cable runs to around 100 metres, can make hardwired systems complex and costly on larger projects.

Addressable damper systems offer scalable control and real-time status monitoring, supporting complex cause-and-effect strategies. These systems can manage large numbers of dampers efficiently, and are increasingly integrated with building management systems (BMS) for proactive fault detection and maintenance.

At the heart of any damper control strategy is cause-and-effect logic. In relatively simple buildings, the cause-and-effect may involve closing all dampers upon fire alarm activation. In more complex environments, however, more sophisticated control is required. In hospitals, for instance, it may be necessary to maintain air supply and extract in operating theatres during a fire elsewhere, meaning damper responses must be based on specific zone requirements.

Similarly, large basements and car parks require selective smoke extraction, supplying fresh air to the fire zone while isolating adjacent areas to contain smoke spread. Addressable systems allow these complex and dynamic responses to be programmed and adjusted as the building’s use evolves.

Typically, a dedicated damper control panel will manage the control and monitoring of dampers. Dedicated panels will typically provide facilities for scheduled damper testing, remote monitoring, and fault reporting. Firefighters’ override functionality may also be provided, depending on the application. Integration with the BMS enables centralised management and further supports ongoing maintenance regimes.

It is essential that all elements of the smoke control system – not just the dampers, actuators and control panels, but also the interfacing electronics, network cabling and related control components – are adequately protected from fire. In MA systems in particular, thermal protection must be continuous across the system to ensure it remains operational during the early, critical stages of a fire when smoke control is most vital.

While both NSHEVs and smoke control dampers support smoke control, NSHEVs differ in that they vent smoke directly to the outside via the roof or façade, using natural buoyancy or wind pressure rather than ducted extraction. By allowing smoke and hot gases to escape from a building, NSHEVs help to maintain visibility, lower internal temperatures and support safer conditions for firefighters.

Certified under BS EN 12101-2 Smoke and heat control systems – Natural smoke and heat exhaust ventilators, NSHEVs must meet stringent requirements for aerodynamic free area, reliability under fire conditions, and resistance to adverse environmental factors. Properly designed NSHEV systems can significantly improve evacuation conditions, particularly in large volume spaces such as atria, shopping centres, and warehouses.

Two versions of BS EN 12101-2 coexist. The 2003 version remains the harmonised standard listed under the CPR, and is the only version that can be used to support CE or UKCA marking. Although a revised edition was published in 2017 with updated and clearer guidance, it has not been harmonised and cannot be used for regulatory compliance purposes.

A growing trend is the dual use of NSHEVs for both smoke control and natural ventilation. In these applications, the ventilators respond to environmental conditions such as CO₂ levels, indoor temperature and weather, helping to maintain indoor air quality during normal operation. In the event of a fire alarm, the system overrides the environmental controls to prioritise smoke clearance.

This dual-function approach – common in schools, care homes and office buildings – requires actuators and control systems to be cycle-tested for frequent use without compromising life safety performance. NSHEVs used for both smoke control and natural ventilation must be certified for dual use, including additional cycle-testing. Common errors – such as specifying manual-only vents or obstructing the aerodynamic free area – can compromise performance and should be avoided. Retrofitting actuators to standard windows without full testing under BS EN 12101-2 may also lead to non-compliance and potential system failure in a fire.

The integration of damper and NSHEV systems with a BMS is becoming increasingly common, enabling more effective monitoring and control. Test results, fault notifications and maintenance alerts can integrate into central dashboard that can be accessed remotely.

Emerging technologies are influencing the design and operation of life safety systems. For example, environmental control strategies can be layered onto damper systems, using occupancy sensing and temperature data to optimise heating, ventilation and air conditioning (HVAC) efficiency under normal operation, with fire control priorities overriding environmental settings during an emergency. In large projects, particularly hospitals and data centres, multiple damper control panels can be networked, allowing coordinated cause-and-effect strategies across multiple zones, and supporting phased evacuation strategies where necessary.

Specifiers must ensure that only CE- (or UKCA-) marked, fully tested products are used, that cause-and-effect strategies are appropriate and documented, and that maintenance regimes are in place and verifiable. Wherever possible, early engagement with manufacturers’ experts can ease, and inform, fire strategy development. Accurate damper specification – clearly defining criteria such as classification, installation orientation, pressure rating, leakage class and actuation method – is critical to avoiding costly over-specification or inappropriate product selection.

Figure 3: An example of UKCA-marked NSHEV, tested to BS EN 12101-2, for integration into an external wall (Source: Swegon)

Design teams should engage with manufacturers early to ensure compliance with smoke control standards. Regulatory changes following the Building Safety Act are likely to place even greater emphasis on the demonstration of competence, accountability, and traceability in the design, installation and maintenance of life safety systems.

Testing and commissioning are vital to ensure dampers and NSHEVs function correctly in a fire. Full system testing should confirm device operation, response to alarm inputs and performance under fault conditions. The code of practice BS 9999:2017 Fire safety in the design, management and use of buildings, and the residential version BS 9991:2024, emphasise the importance of ongoing maintenance, with specific recommendations for testing regimes. In all cases, work must be carried out by competent persons, with issues promptly addressed and records properly maintained.

Fire dampers, smoke control dampers and NSHEVs are critical, complementary tools in building fire strategies. Their correct specification, integration, control and maintenance directly impact the ability of a building to protect life during a fire event. As regulatory expectations rise, delivering compliant, well-maintained smoke control systems is not only essential for safety but integral to professional practice.

© Tim Dwyer 2025.

With thanks to the team at Swegon for sharing their expertise, experience and thoughts in the creation of this CPD article.

Further reading:

CIBSE Guide E: Fire Safety Engineering – particularly Chapters 10 and 12, which cover smoke control systems, compartmentation, and damper integration.

CIBSE Journal CPD Modules 44 and 155 – provide additional detail on damper types, testing requirements, and their role in compartmentation and life safety strategies.