The new secondary school in Houlton, on the outskirts of Rugby

On the outskirts of Rugby is a collection of Grade II listed 1920s buildings that originally housed Rugby Radio Station’s radio transmitter. First opened in 1926 to send radio messages to the Commonwealth, it continued to evolve so that at its zenith in the 1950s it was the largest radio transmitting station in the world.

Formerly known as C Station, it consisted of two main buildings; the taller Transmission Hall housed its large, very low frequency transmitter, while the shorter Power Hall was home to the generators.

When it was built, the building stood in fields circled by an array of 57 aerial masts, 12 of which were 250m high. Now, the radio buildings are in the centre of an emerging new mini-town named Houlton, which is being jointly developed by Urban & Civic and Aviva Investors.

As part of the new development the listed radio station buildings have been innovatively incorporated into a new secondary school for 1,200 students in the heart of the development.

Architect van Heyningen & Haward’s (vHH) design for the school is based on five blocks. It is a scheme of two parts: the two repurposed listed structures, along with three new blocks. All the conventional teaching spaces are grouped into two of the new blocks, one of which houses classrooms for teaching humanities, the other incorporating laboratories for science teaching. A sports hall makes up the third. The remaining functions are fitted into spaces in the existing buildings.

Minor adaptions enabled the Power Hall to accommodate the school’s dining and assembly halls. More significant interventions were needed in the Transmission Building, including the addition of a new internal steelwork frame, threaded through the first floor slab, to provide an additional three storeys of accommodation for the teaching of art, music and dance, along with a new top floor, to replace the roof destroyed in a fire, which is now the sixth form space.

The Education and Skills Funding Agency’s (ESFA) output specification set minimum energy performance requirements for the new buildings. However, there were no ESFA targets for the repurposed existing buildings, a factor that could have resulted in the school having to use more energy to maintain comfort conditions than it would, had these spaces instead been accommodated in new school buildings, which would eat into its fixed operational budget.

Architect van Heyningen & Haward’s solution was for the new blocks to maximise energy efficiency by aiming for fabric thermal efficiencies close to Passivhaus standard, while the existing blocks would be as energy efficient as possible within their heritage context. The rationale being that by building to best practice energy efficiency standards, the new blocks would use less energy than they would if they had been built to comply with the Building Regulations minimum.

The thinking was that the new block’s low energy consumption would help offset the higher energy use of the repurposed buildings, with the result that the ongoing overall operational cost to the school would be similar to that of a new build school.

The more you can bring the loads down, the smaller the plant, which in historic buildings like these is really important as it reduces the extent of intervention required

About a third of the school’s accommodation is in the formerly unheated radio station buildings, so one of the design team’s first tasks was to develop suitable improvements to the buildings’ envelope. Following a point cloud survey, the project’s energy consultant, Etude, worked closely with the architect on developing modifications to the fabric to make it as energy efficient as possible.

Although Etude challenged vHH to find areas that could be insulated externally, Etude director Will South says internal wall insulation ‘was the inevitable strategy’. The problem with internal insulation is that it introduces the risk of moisture build-up and potential damage to the 100-year-old walls.

To assess the risk, Etude modelled the conditions using the dynamic hygrothermal simulation tool, WUFI. As a result of the modelling, the thermal performance of the walls have been improved using a breathing wall construction incorporating open wood fibre insulation, with the overall thermal performance designed to maintain a U-value greater than 0.4W·m-2·K-1 to help limit moisture build-up.

Etude ‘modelled the whole site,’ according to South. ‘We used TM54 methodology with part dynamic simulation and part Passivhaus Planning Package (PHPP)’. PHPP was used to calculate the predicted heating energy for the new buildings and the existing buildings. ‘We find it more reliable for predicting heating energy and you’re more in control of the assumptions,’ he explains. On the existing buildings, as the insulation increases he says PHPP ‘gets more and more accurate because your temperature doesn’t fluctuate as much’.

Alongside fabric thermal improvements, the team also set out to minimise the existing buildings’ fabric air permeability. For the Grade II listed buildings an aspirational air permeability target of 3m3·h-1·m-2 was set with a backstop minimum of 5 m3·h-1·m-2, while for the new build an aspirational target of 1m3·h-1·m-2 at 50Pa was set with a backstop minimum of 3 m3·h-1·m-2.

Historical equipment from the radio station has been left in situ

Work to the existing fabric included removal of the historic plaster to expose the wall so that problem areas could be repaired. In addition, most of the leaking, single-glazed windows were replaced with bespoke lookalike high performance units, and in some cases, with the addition of secondary glazing.

The fabric modifications were successful; tests showed the actual air permeability of the Power Hall was less than 3m3·h-1·m-2, while in the Transmission Hall it was still less than the 5m3·h-1·m-2. backstop.

Most of the leaking, single-glazed windows were replaced with bespoke lookalike high performance units, and in some cases, with the addition of secondary glazing

‘The success in reducing the air permeability in each building to this extent shows what can be achieved in historic buildings like this,’ says Amy Punter, an associate director and historic building specialist at Hoare Lea, the project’s MEP engineers.

‘The reason minimising air permeability is so important, is that it brings the heating loads down to a manageable level; without that we would have had to install considerably more plant, which would have been a real problem given its listed status,’ she says.

Etude and Hoare Lea worked in close collaboration. Punter says that while Etude was developing the energy targets, Hoare Lea was carrying out studies to assess the targets’ impact on loads and implication for plant sizes. ‘The more you can bring the loads down, the smaller the plant, which in historic buildings like these is really important as it reduces the extent of intervention required,’ she says.

All teaching spaces in the historic buildings have mechanical ventilation, although the ESFA is not generally in favour of it.

Handling air

The use of AHUs was contentious because the ESFA is not generally in favour of mechanical ventilation, says Punter. ‘Because we were targeting an air permeability akin to Passivhaus standards in the new build blocks and were targeting significant reductions in the air permeability of the existing buildings, a need for mechanical ventilation was established, particularly when the benefit of heat recovery was taken into account in the energy consumption calculations,’ she explains.

Air handling plant is located internally on the historic buildings to avoid external additions; air intakes and exhaust louvres are located in dummy windows to minimise visual impact. The air handling units each have an integral reverse cycle heat pump, which has the benefit of providing an element of cooling to temper the supply air in summer. Two air handling units also serve each of the new build teaching blocks; these are located in enclosed rooftop plantrooms to provide protection, reduce visual impact, and reduce long term maintenance.

The only space without mechanical ventilation is the sixth form space on the top of the Transmission Hall because it has opening windows on two elevations to make use of the opportunity to cross ventilate. All classrooms and areas with occasional high occupancy levels, such as the main assembly space, have option of opening windows should temperature and/or CO2 levels get too high.

The new blocks are orientated north-south to reduce overheating risk and maximise the opportunities for winter solar gain. On the north elevation, windows are in line with the facades to maximise daylight in the classrooms, whereas on the southern elevation brick fins shade the triple glazed windows and their hinged side ventilation panels that allow additional natural ventilation.

The teaching blocks’ low energy design meant that their heat loads were low enough to enable heating using air source heat pumps (ASHPs). Wall mounted radiators sized for a 45oC flow temp heat the classrooms while ceiling mounted radiant panels, also sized for a 45oC flow temperature, are used to provide heat to laboratories and larger spaces. ‘Heat pumps were a relatively unusual solution at the time and we were keen to show what a new build school could look like with this technology, but now most new buildings are being heated with these,’ says Etude’s South.

A computer generated image of the site

Heating design guidance

He says that this project highlighted the need for design guidance to keep pace with the evolution of heating systems. In particular, he says there is an issue with heat emitter sizes designed for buildings with a very low heat load, which he says ‘could lead to emitters being oversized’.

South also says that design standards often assume new buildings lose heat at a faster rate than they do in reality, which reduces the need for redundancy in heating plant because ‘redundancy has effectively been built into the fabric’. As a consequence, he says there is often an opportunity to reduce the amount of the heating plant to help balance the cost of fabric enhancements. ‘On the new build school blocks, it would probably be a week before they’d notice the heat pump had failed,’ he laughs. On this project he says Hoare Lea did ‘a really good job of striking the right balance’.

Domestic hot water (DHW) is supplied using direct electric heating at point of use in the two new teaching blocks and the Transmission Hall. South says the project took ‘quite a big hit’ with the ESFA for using electric.

‘Because measured hot water use by a school is quite a lot lower than the Part L assumption, you can end up in a situation where you pay for a lot of kit to make the production of something that you’re not using much of, very much more efficient, with the result that the main cost is then circulating hot water around the school,’ he explains.

The Power Hall houses the dining and assembly hall

Because the school will not be fully occupied for several years, there was an additional benefit to only heating the water being used.

Gas is used to heat the new sports hall block and the two historic buildings. Three heating boilers and a gas-fired direct water heater that provides hot water for the sports hall showers are located in the sports hall plantroom. Locating them in one of the new blocks avoided the need for a flue on the historic blocks.

The sports hall services are configured to shut off links to other buildings using valves and dampers to enable the community to use certain areas of the building out of school hours.

Soffit-mounted, low temperature hot water radiant panels, based on a 70oC flow temperature, heat the sports hall and the double and triple height spaces in the historic buildings, including the assembly and dining halls.

The gas-fired boilers also heat the domestic hot water, via a buffer tank, to the toilets and school’s kitchen in the Power Hall building. South says the use of gas would be ‘something we’d look to change if we were designing the project now, because it would be possible to provide heat with a heat pump system’.

The project used a design and build contract. Following an as-built analysis, the design team concluded that in future they would provide contractors an energy consumption impact with all proposed value engineering options, and that they would monitor estimated energy consumption impact of any design changes proposed.

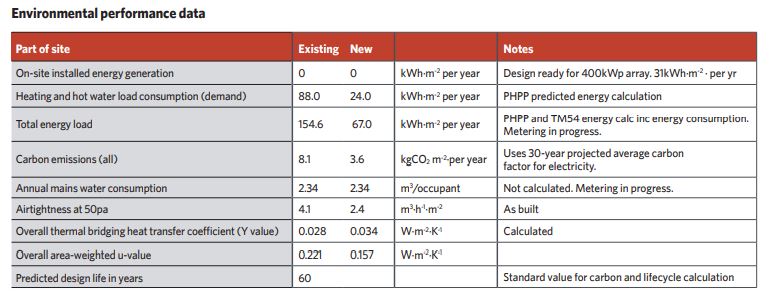

The final (as-built) predicted energy consumption meets DfE requirements, and is in the 10th percentile for new schools, with an average heating energy demand of about 25 kWh·m-2 per year for the new buildings.

What this project shows is that with a creative architect and innovative approach to low energy and building services design it is possible to repurpose almost any historic structure.

This is important because we need to prioritise the retrofit of existing building stock over demolition to help minimise the carbon embodied buildings and Houlton School shows that retrofit can deliver something unique and exceptional.