The insides of a valve showing local element corrosion

There has been substantial growth in the UK district energy market in the past five years. Ongoing maintenance of these networks is vital to ensure a sustainable payback of the capital investment in plant and equipment, and to keep downtime – and disruption to the end user – to a minimum.

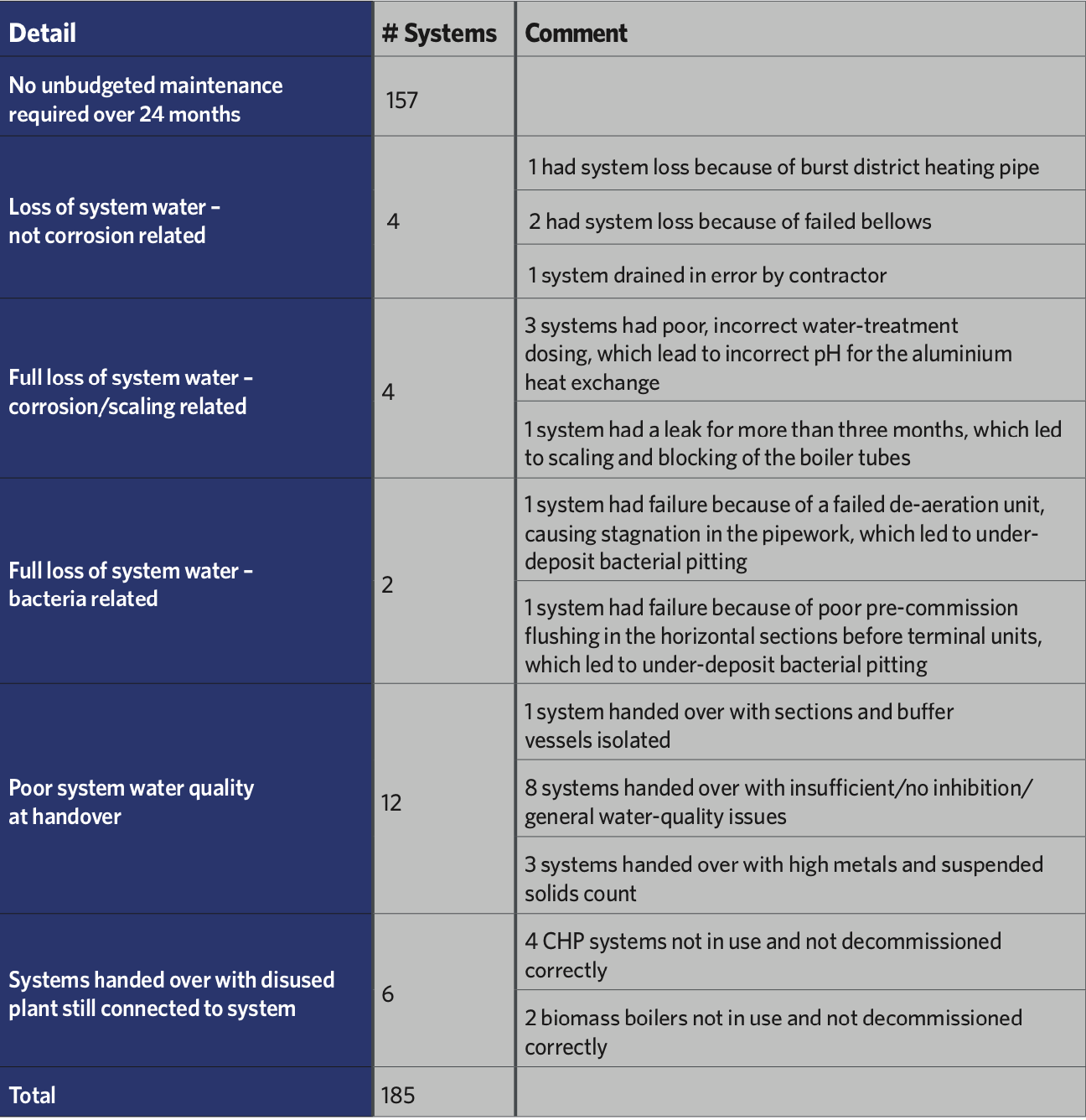

A study carried out into heat network water quality in the UK gave examples of current system issues and offered guidance on avoiding high-cost failures within systems’ lifetimes. It considered design stage, pre-commission stage and ongoing management, and 185 systems were studied, with particular interest given to failures and the root cause of these.

The study found that improvements could be made to water-treatment design and implementation throughout the process: design, build, pre-commission, handover and ongoing maintenance. Improving water treatment at these stages will lead to systems running more efficiently, minimise downtime, avoid non-budgeted capital expenditure, minimise disruption for end users and extend the life of the system.

The 185 systems across the UK had their water quality monitored for bacterial contamination and chemical composition of the system waters for 24 months. System volumes varied between 10,000 litres and 1,800,000 litres.

Issues occurring within 185 systems monitored for the UK heat network water-quality study

Key findings

Design and pre-commission

- Inadequate pre-commission cleaning of horizontal pipe runs/laterals before the terminal units and not in accordance with agreed specifications

- CHP and biomass not being used/left stagnant

- Lack of good practice for storage of district heating pipework, especially when laying in trenches (for example, pipework not suitably capped), allowing ingress of debris to the system during build stage

- Systems handed over with inadequate certification and reporting

- A lack of independent audit process at handover

- Metallurgy of system not considered for water treatment

- System size not considered for water treatment

- Lack of continuity in water treatment for staggered build networks

- Inadequate flushing velocities achieved in >150mm bore pipework

- Lack of automatic water-treatment dosing systems on networks

- Lack of side-stream filtration on networks

- Lack of remote water-quality monitoring on networks.

On-going management

- System leaks leading to ingress of oxygen and dissolved solid precipitation from the mains water supply feed

- Incorrect water-treatment choices for metallurgy of system

- Lack of monitoring and maintenance of filtration equipment

- Lack of monitoring and maintenance for water treatment after practical completion

- Bacterial proliferation in stagnant areas

- Over dosing/under dosing of chemistry

- Lack of live monitoring systems to flag up issues.

Conclusions

Currently, there are gaps in the design, operation and guidance for water-treatment in the UK district energy sector. The following should be borne in mind:

Considerations at design stage

- Minimise areas of potential stagnation

- Specify suitable side-stream filtration for all district energy systems

- Specify that fill water is deaerated

- Specify that district heating systems have continuous monitoring for pH and conductivity as a minimum. The system should also be able to report remotely – either via the BMS, or email/SMS – to indicate failure of the control levels to suitable stakeholders

- Water treatment should be specified to be ‘automatic’ in nature

- Water treatment, fill water quality and method and pressurisation should be considered at design stage, based on system volumes and metallurgy. If secondary and tertiary systems are to be filled from the ‘primary’ network, consideration must be given to ensuring no conflicts between the water-treatment regimes of both systems.

Consideration for pre-commission stage

- For pipework >150mm diameter, alternate flushing methodology to BSRIA BG29:2012 should be sought – for example, ice pigging and traditional pigging

- Improve record-keeping and audit processes during precommissioning works and implement a daily log of works on site

- Have an independent audit of the works before handover

- Consider existing water treatment when connecting new systems to ‘old’ networks.

Sludge and biofilm removal from a district heating system

Ongoing considerations

- Stagnation should be avoided – any stagnant areas should have full velocity and heat flushed through for a minimum of two minutes every four days

- ‘Legacy’ equipment no longer in use should be decommissioned and disconnected from the system waters, leaving no ‘dead-legs’

- Side-stream filtration should be monitored and managed on a pro-active basis, to ensure suspended solids are removed as required

- Continuous monitoring and automatic dosing should be installed on all district heating networks to minimise the risk of corrosion and associated water treatment issues.

Improved water-quality treatment in UK heating networks will prevent non-budgeted capital expenditure, minimise disruption for end users and extend the life of the system.

Jon Greaves is national technical manager at Hydro-X Water Treatment