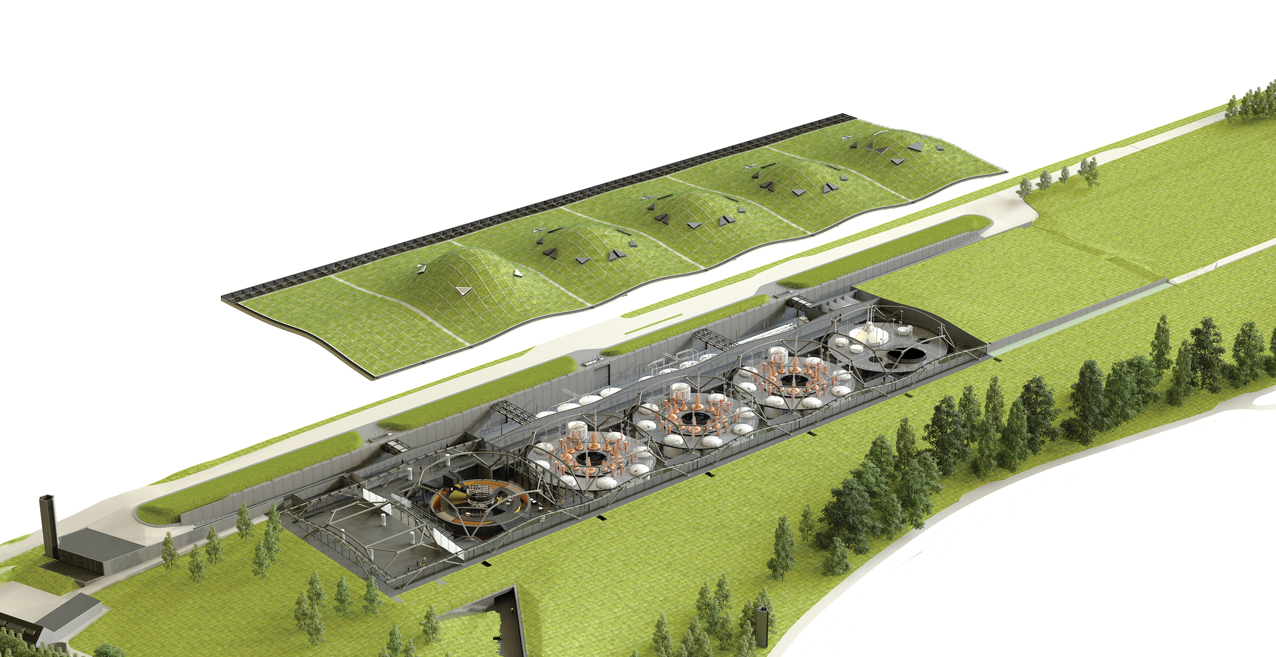

The design of The Macallan’s new £140m distillery successfully combines a state-of-the-art whisky distillery with a dynamic visitor experience in a single building. Designed by Rogers Stirk Harbour + Partners, working with engineers Arup, the 14,800m2 building is cloaked by a laminated-timber grid roof, incorporating four circular hillocks and a fifth larger one. Its undulating surface is covered by native grasses and wildflowers to help it settle into the landscape of the northern highlands of Scotland.

‘The form of the building is dictated by the production process; distilling generates a lot of heat, so the roof has been domed over the distilling vessels,’ says Adam Jaworski, structural engineer at Arup.

The building is aligned along a north-south axis. At its northern-most end, one of the small domes covers the mash hall (see panel, ‘How malt whisky is made’). The dome is accompanied by a line of three similarly sized mounds, each emphasising the location of the distillation halls, with their unique circular arrangement of onion-shaped copper stills below. This spectacular roof shelters what is, effectively, a single-storey distillery, with the exception of a small mezzanine floor that affords visitors an aerial view of the production plant. The fifth, larger dome marks the visitor centre, bar and obligatory shop.

The distillery roof’s undulating surface is covered by native grasses and wildflowers

Two of the biggest challenges the engineers had to deal with when engineering the distillery building were heat and ethanol (alcohol) vapour. Macallan’s process engineers use the ATEX hazardous area classification system to identify places where ethanol vapour might concentrate and create a potentially explosive atmosphere. All classified areas required special precautions to prevent sources of ignition – such as switches and controls – from causing a fire or an explosion.

Classification varies from Zone 0 to Zone 2:

- Zone 0 is a place in which an explosive atmosphere is present continuously – such as in the vessels and stills

- Zone 1 is a place in which an explosive atmosphere is likely to occur occasionally in normal operation

- Zone 2 is a place where an explosive atmosphere is not likely to occur in normal operation but – if it does occur – it will persist for a short period only. Generally, the lower area of the distillation halls, below mezzanine floor level, are Zone 2.

In addition to ethanol vapour, the other big challenge the engineers had to deal with was heat. ‘In the production part of the building, there is an awful lot of heat from the whisky-making process, which is dispersed by a mechanical ventilation system,’ says Jim Deegan, mechanical engineer at Arup.

This ventilation system draws in air at low level from a trench recessed into the ground bounding the east side of the building. This untreated air is then divided into two, with half ducted to the west side of the building through large concrete ducts constructed beneath the process hall. Banks of fans push this fresh air into the distillation hall at low level to help cool space and to dilute the ethanol vapour present.

‘The system runs continuously to ensure that the air in a zone 3m above the floor changes six times per hour,’ says Deegan. ‘Above this 3m zone, the solution relies on the natural process of heat rising up from the plant to dilute the ethanol vapour.

The warmed air exits the building through a series of triangular vents set into its undulating roof. The expected concentration of ethanol vapour in the air means that the roof area adjacent to the vents has an ATEX Zone 1 classification. Ethanol concentration will be at its highest here when the washbacks and stills are being filled with a new charge of liquid, a process that displaces the concentrated ethanol vapour from inside the vessels.

How malt whisky is made

Barley is malted by steeping it in water and spreading it out on malting floors to germinate. This process activates enzymes. After about a week, the barley is dried in a kiln kept at a temperature below 70°C, so as not to destroy the enzymes. The dried malt is then ground into a grist – a process that takes place outside the distillery building

At The Macallan’s new distillery, the grist is mixed with borehole water and heated in a mash tun, housed under the first dome of the roof, at the northern end of the building. In this vessel, the barley starches are converted to sugar by the enzymes activated by germination. The sugary liquid wort is then cooled to about 20°C and pumped into giant, stainless steel vessels, called washbacks, where yeast is added and fermentation begins (the yeast converts the sugar to alcohol). This takes a minimum of two days, after which the ‘wash’ will contain about 8% alcohol by volume.

Rogers Stirk Harbour + Partners’ design incorporates the fermentation and distillation vessels into circular clusters beneath the three remaining small roof domes. To concentrate the alcohol in the wash, it is distilled in the big copper pot stills. In the wash still, the wash is heated to just below boiling point so that the alcohol and other compounds vaporise. This vapour is condensed back into a liquid in the neck of the still by a large copper coil, kept cool by passing water through it from the River Spey.

The distillate, known as low wines, now contains about 20% alcohol by volume. This is transferred to a spirit still, where it is distilled for a second time to produce a spirit that is about 68% alcohol by volume.

The final part of the process is storing this colourless spirit in oak casks – which may have contained sherry or bourbon previously – for 10 years or more, for maturation into single malt whisky.

Classifying the roof area around the vents as Zone 1 means the lightning-protection scheme incorporates masts to lift the finials above the Zone 1 area.

As might be expected, the distillery incorporates a cutting-edge fire-protection system, incorporating a combination of sensors: conventional optical sensors; Very Early Smoke Detection Apparatus (Vesda); and ethanol gas detection, flame and heat detection.

Detailed fire-engineering predictions allowed the roof to be kept free of sprinklers, although these are present on both sides of the giant, glazed fire-compartment wall that offers a transparent division between the production facility and the visitor centre. This fire-rated wall is kept cool by sprinklers, which spray on the side where a fire has been detected. A representative, full-scale sample of the components that form this solution was tested at BRE.

The southern end of the building houses the visitor centre, which includes a circular basement – called the Cave Privée – the walls of which support 300 wooden casks of maturing whisky. A small air handling unit (AHU), incorporating an evaporative cooler, maintains conditions in this space at 12°C, 70% RH, to regulate evaporation from the casks.

A small AHU, incorporating an evaporative cooler, maintains conditions in the circular basement at 12°C, 70% RH, to regulate evaporation from the casks

Ventilation to the visitor centre is provided by a single, large AHU. This maintains comfort in the summer by keeping a high air-change rate while, in winter, heat generated by the whisky-making process is reclaimed to heat the space. ‘After the river water has been used in cooling the condensers, it comes back to a holding tank before being returned to the river,’ says Deegan. ‘We use a small fraction of this heat to heat the building.’

Sustainable heat for the process plant comes via steam mains from Estover’s Speyside combined heat and power (CHP) plant, about 2km from the distillery. The plant burns local farm and forestry waste (there are 750,000 acres of forestry within 50 miles of the plant), plus waste products from the distillery, to generate 12MWe. ‘The Macallan distillery uses about 80% of the steam produced by the plant and some of the low carbon power it generates,’ says Deegan.

The plant should keep the distillery fed with low carbon steam for 95% of the year. When the plant is not running, the distillery has two gas-fired boilers, rated at 10MW each, which produce 18MW of medium-pressure steam. These are at the south end of the building, and connect to the process area via a corridor.

The visitor centre opened to the public in June 2018, but spirit production has been in full swing at the plant since December 2017. For tourists and whisky pilgrims, this impressive new facility marks a significant milestone in the development of the industry in the 21st century.

The form of The Macallan building is dictated by the production process. Distilling generates a lot of heat, so the roof has been domed over the distilling vessels. The largest dome marks the visitor centre

Shedding light on whisky production

‘The client had the enthusiasm to do something brave and exciting,’ says Clementine Fletcher-Smith, associate partner at Speirs + Major, the project’s lighting designer. ‘We could have lit the distillery simply to look beautiful, but we also wanted the lighting to help tell the story of how whisky is produced.’

The concept for the building had been established by the time Speirs + Major became involved. For a scheme that initially appears to be buried in the grounds of the Easter Elchies estate, the long, thin building is fully day-lit on one side – so the starting point in developing the lighting scheme was a daylight study. ‘The majority of visitors will come in the summer, when it is light up to midnight, so the design needed to have an impact on a bright summer’s day, as well as on a dull winter afternoon,’ says Fletcher-Smith.

The major challenge in lighting the distillery was to establish the extent of the ATEX hazardous area classification zones. These are based on the likely concentration of ethanol fumes in an area, making it potentially explosive. ‘When we started our design, the whole plant was classed at the highest rating, which severely limited the kit we could use. As the process design progressed, however, the zoning became less restrictive, so only a one-metre zone immediately surrounding the production plant and the area below the mezzanine deck, plus the Cave Privée, were ATEX zones,’ says Fletcher-Smith.

The entire scheme is lit by LEDs. In response to the zoning, all of the dynamic light fittings – RGBW spotlights – are located above the mezzanine/visitor level in the production area. Below the mezzanine, ATEX-compliant LED floodlights, fitted with dichroic filters, are used. To achieve ATEX compliance, the starting point was an IP68 fitting, which was then subjected to additional tests. ‘We knew the colour hues we wanted, so the ATEX-compliance testing was carried out on one IP68 fitting, which was then fitted with different colour filters,’ says Fletcher-Smith.

Above the mezzanine, the dynamic fittings are installed on lighting columns, which are next to the process vent-pipes. ‘The architect’s concept was that the roof appears to float freely over the landscape of the production plant, so we arranged the light fittings into clusters surrounding the vent-pipes,’ Fletcher-Smith explains. The lighting infrastructure was also coordinated with the precisely and neatly arranged process pipework.

Alongside the dynamic lighting scheme, Speirs + Major had to ensure the production engineers were able to produce the spirit that is matured into whisky. ‘The building is, effectively, a factory, so there is a layer of robust functional lighting to enable the production team to do their job. This is overlaid by much more dynamic lighting with a theatrical control system, to provide the visitor experience,’ says Fletcher-Smith.

There are two modes of dynamic lighting: an automated set of scenes that sequence throughout the day, to create a dramatic backdrop to the visitor centre bar; and one that uses a theatrical control system to enable the distillery to run visitor tours of the plant. These are led by a guide who uses a tablet computer to cue programmed scenes, which vary from a strong focus on a single entity to a full-lit view of the space.

Colour is used to give visual cues; cool blue for the stainless steel cold-process equipment, and amber-red hues for the hot copper stills. ‘At the beginning of the tour, all lighting in the process plant is turned off, so that the interior is day-lit and the views are out to the landscaping. As the tour commences, the washbacks are lit up, followed by the stills and so on, to provide a sense of revelation,’ says Fletcher-Smith.

The tour culminates in an immersive experience in the Cave Privée, a circular whisky store where programmable dynamic light combines with black polished surfaces to create kaleidoscopic effects.

A visitor centre adjoins the production plant, and includes a bar and exhibition space. It is separated from the production plant by a glass screen, so visitors can see it lit. In the visitor centre, Source Four LEDs are used to provide a colour overlay to the space. ‘We worked with exhibition designers to integrate lighting with audio visual exhibits,’ says Fletcher-Smith.

Project team

Architect: Rogers Stirk Harbour + Partners

Structural, fire, building services and civil engineering: Arup

Exhibition designer: Atelier Bruckner

Landscape architect: Gillespies

Lighting consultant: Speirs + Major

Process engineer and fabricator: Forsyths

QS and PM: Equals consultancy

Main contractor: Robertsons Construction Group