The past decade has seen the demise of the hot water tank in many homes, as improvements in combi boilers – which combine delivery of hot water for space heating and domestic hot water – mean occupiers can have efficient instantaneous hot water without the need for a storage tank.

Hot water cylinders are still needed in larger homes, however, where more hot water is required. More than 450,000 hot water tanks are still sold annually, and the government’s target of 600,000 heat pumps installed by 2028 will boost the market, as heat pumps require cylinders with heat exchangers to deliver hot water.

The potential to store energy is another benefit of a hot water cylinder. As well as enabling energy to be stored from local renewables, they could store excess energy generated by wind and solar on the National Grid.

Innovate UK and the Department for Business, Energy and Industrial Strategy (BEIS) has been carrying out trials to see how tanks can integrate renewables in the home and connect with other tanks to offer a demand side response (DSR) to the National Grid.

One of the sector’s pioneers is Mixergy, a spin-out firm from Oxford University’s Energy and Power Group. Its hot water tanks featured in a BEIS DSR pilot where connected tanks were heated by the Grid when national electricity demand was low and excess energy was being generated by renewables. Storing this excess energy in a large-scale battery of hot water tanks allowed more electricity on the Grid to be generated using wind and solar.

Case study

Mixergy tanks were installed in 78 East Devon District Council properties, alongside a Vaillant air source heat pump, PV panels, and a PV diverter, to allow the solar panels to charge the hot water tank. Insulation was topped up in the roof to improve the ability to retain heat, and radiators were upgraded. Using SAP, it was calculated that the retrofits lifted homes from EPC band E to B at a cost of around £15,000 per property.

Building on this pilot, Mixergy is now remotely operating 700 of its customers’ tanks to offer a DSR service for the Grid. ‘The tanks provide a stabilising service for the Grid,’ says Mixergy CEO Pete Armstrong. ‘The frequency response service is quite rare and hardly changes heating patterns. The typical cost of a frequency event is only 1-5 pence, and it only lasts a few minutes and usually adds to heating that is required anyway.’

Hot water tanks are the lowest-hanging fruit in terms of energy storage, he adds. ‘There’s a huge dormant capacity in hot water tanks. Of the 27 million homes in the UK, about 40% have a tank as part of a system boiler or direct electric. Collectively, this represents about 85GWh of energy storage, which is just over nine times the size of Dinorwig Power Station in Wales [which provides rapid-response capability in the Grid],’ says Armstrong.

Heating the hot water required reduces energy use, cuts heat losses, and leaves spare capacity to store energy from renewables, such as photovoltaics

Armstrong says using hot water tanks as energy storage batteries is a lot cheaper than using lithium batteries, and use far less resources in their manufacture. ‘Lithium-ion batteries are expensive and take a decade to pay for themselves, by which point they’re dead,’ he says. ‘Batteries are incredibly material intensive, containing around 80kg of cobalt, lithium and copper compared with 30kg of, predominantly, stainless steel and polyurethane in a hot water tank with equivalent energy storage density.’

How it works

Mixergy’s hot water tank technology differs from traditional tanks by heating from the top of the tank. It uses stratification to keep hot water at the top of the tank separated from the cold water below. An electric immersion heater and heating coil from the system boiler is installed at the top of the tank. A cold water mains feed enters the bottom of the tank and a pump takes this water, internally, to the top of the tank, where it is sprayed via a diffuser into the hot layer and heated by the heating coil or immersion heater.

The Mixergy tank is heat-pump ready but is designed to maximise the efficiency of a gas boiler

The hot and cold layers are separated by a thermocline – a thin distinctive layer that changes temperature dramatically from hot to cold. It’s important that the thermocline is not disturbed, to maintain the separation of the layers, says Armstrong; a novel array of temperature sensors ensure that the pump turns down if movement in the water threatens the integrity of the thermocline.

Having a separate layer of hot water means that the whole water tank does not have to be heated, and a built-in controller can ensure the tank is charged incrementally.

Heating the hot water required, rather than the whole tank, reduces energy use, cuts heat losses from the tank, and leaves spare capacity to store energy from renewables, such as photovoltaics.

It also means that recharging the hot water tank is faster, as Mixergy’s director of business development, David White, explains: ‘As we are only heating small portions of water, we can heat up much faster than a conventional tank.’

He uses the example of a 180-litre tank running alongside an 20kW gas boiler. To heat up 36 litres of water (enough for a shower), only 20% of a Mixergy tank would need to be heated, taking around 5.5 minutes. A conventional heater would take five times as long, says White.

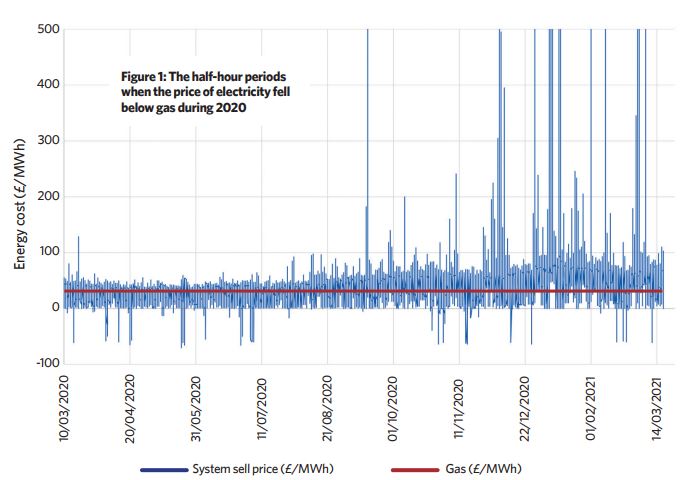

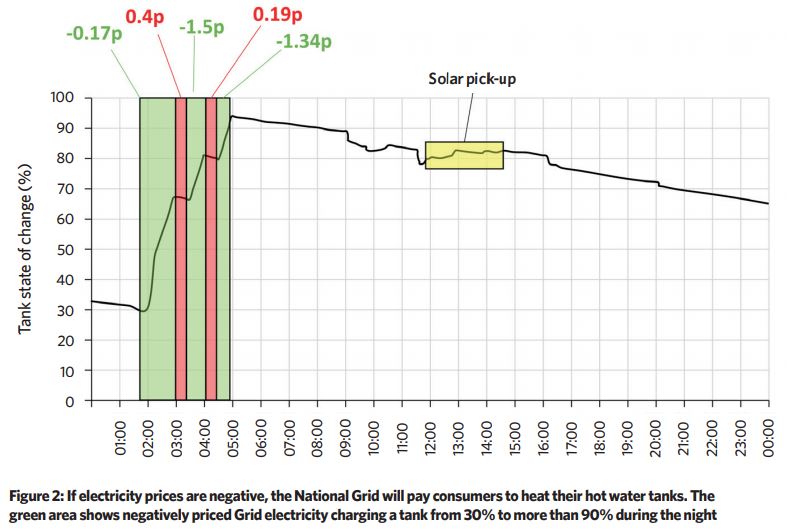

Machine-learning software built into the tank’s controller is designed to switch to the lowest-cost energy source when heating. It accesses half-hourly electricity prices issued by the National Grid, and automatically recharges during half-hour periods when prices are low or even negative. Figure 1 shows the half-hour periods when electricity prices fell below gas last year. Figure 2 shows how one customer was credited for heating the tank when prices were negative.

The tank may use another source of energy – such as gas heating, solar thermal panels or photovoltaics, which communicate with the tank via PV diverters. These are built-in, or the tank can connect to an existing diverter. The intelligent software calculates the cheapest source of energy. If a home has PVs, machine learning will ensure the tank is only partially charged before PVs start generating electricity during the day.

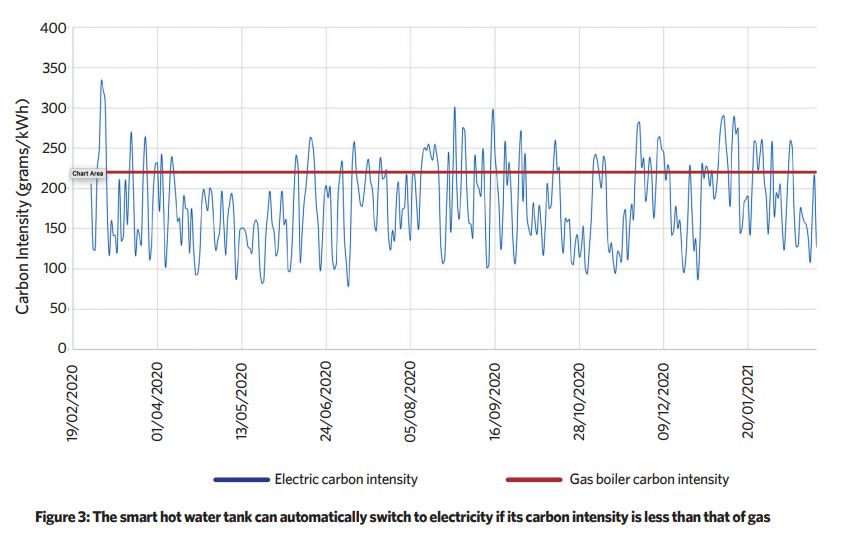

Customers have the option of becoming ‘Mixergy Heros’, where the tank is automatically charged using Grid electricity when the carbon intensity is low (see Figure 3). The software makes decisions based on information from the Grid’s carbon intensity API. Armstrong says tests have shown that carbon emissions fall by around 16% if customers select this option. This means the tanks can take advantage of the increasing decarbonisation of the Grid as more renewables are connected.

‘We spent a lot of time building algorithms for interpreting dynamic tariffs and automatically building schedules that take the burden of thought away from the consumer,’ says White.

Mixergy carried out a trial comparing water heaters using MixCloud with those on Economy 7, which heats water using night-time tariffs. Assuming hot water consumption accounts for £288/year of the average householders’ energy bill,1 the firm says bills for tanks using MixCloud and Economy 7 are £80.30/year compared with £135/year for those just on Economy 7.

With tanks connected through the cloud, the firm can carry out remote diagnostics to identify anomalies. [See panel, ‘Remote diagnostics’] Each tank has, effectively, a Linux computer controlling the heating. As the computing load is light, Mixergy is talking to Berkeley University about using spare computing capacity to contribute to Rosetta@Home life-science research.

The Mixergy tanks have a 25-year warranty and Armstrong is keen to ensure they are future-proof. Mixergy tanks are heat pump ready, so while they can be installed with a system boiler today, every model is fitted with ports to accommodate a plate heat exchanger to operate in future with a heat pump.

This arrangement works more efficiently than a traditional coil, says Armstrong, who claims it delivers more effective volumetric output from the same installation volume and elevates the COP of the system by anywhere between 5-10%. ‘We need to create a product that’s flexible for the low carbon transition, whether its with hydrogen boilers or heat pumps. A core ethos of ours is eliminating product obsolescence,’ he says.

Mixergy’s presence in the market is growing. It has installed around 1,000 water tanks and is aiming to install 5,000 by the end of next year. CJ

REMOTE DIAGNOSTICS

With aggregated data, Mixergy can identify what good performance looks like. It knows the shape of the tank’s heat-loss curve, and can determine the difference between standing heat loss and a draw event. So, if a tank has a higher-than-average heat loss, the team knows there is an issue with insulation.

Anomalies in the data can also identify leaks, limescale on the immersion heater, and whether the boiler is short-cycling. Short-cycling occurs when the boilers’ internal thermostat senses that the water returning from the cylinder is becoming too hot and, as a result, it switches off to avoid over-heating.

Mixergy has created code that recognises short-cycling and lowers the set point temperature of the cylinder to allow the boiler to run continuously. ‘We’re using data to try to spot these issues in the field,’ say Armstrong. The EST has verified that if a boiler is short cycling, a Mixergy tank can help eliminate it, leading to water heating gas savings of up to 21%.

Reference:

1 At home with water, Energy Saving Trust, July 2013 bit.ly/CJApr21EST