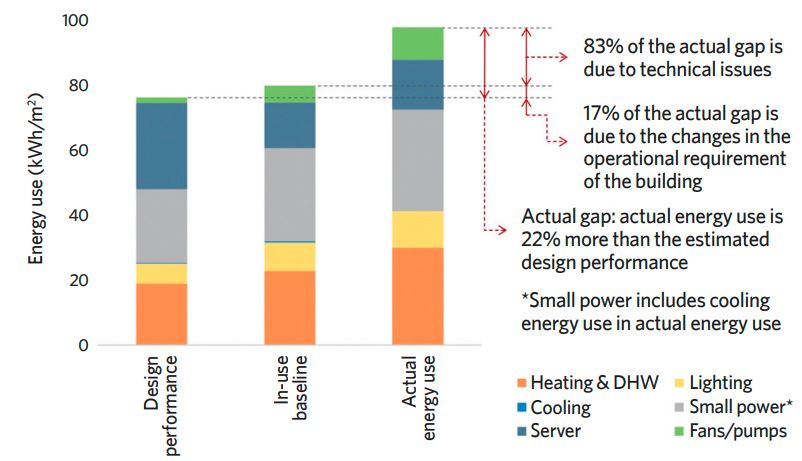

TM63 includes a case study of Keynsham Civic Centre where design and operation stage data was compared to identify performance gaps

Energy performance calculations carried out to comply with the approved associated parts of the building regulations, such as Part L in England or Wales, Part F in Northern Ireland, or Section 6 of Building Standards in Scotland, are based on default or standardised operating conditions. These often do not accurately reflect actual operating conditions of a given building, such as number of occupants, occupancy hours, temperature set points, and schedules of operation of HVAC systems.

Furthermore, regulatory calculations do not report energy use related to equipment (plug loads). Comparing actual energy use of a building with the outcome of regulatory calculations is not an appropriate method for evaluating in-use energy performance.

These regulatory calculations are intended to be simple and suitable for performance evaluations at design stage, and to demonstrate compliance with the requirements after completion. However, the purpose of these compliance checks is not always understood, and outcomes of these regulatory performance calculations are often mistaken for some form of prediction of energy performance for a particular building, which they are not.

In the absence of a robust M&V framework it is not certain that the technical issues uncovered in a building reflect all, or most, of the key causes of the performance gap

To address this, CIBSE TM54 (2013) set out a framework, employing a dynamic simulation method, to provide estimates of the likely operational energy performance of buildings at the design stage. The CIBSE TM54 framework allows designers to tailor the operating conditions based on the client’s brief and expected performance, and accounts for all energy end-uses, including equipment loads.

CIBSE TM54 is intended to be used during design and construction stages, and the tailoring of the calculations for expected operating conditions creates a more realistic design baseline for buildings. This calculation can also be used as a more appropriate baseline for estimating the magnitude of the energy performance gap in use.

The guide also acknowledges the limitations of deterministic energy performance calculations, and provides practical suggestions for uncertainty and sensitivity analysis, to evaluate the sensitivity of outputs to uncertainty in input data that is often inevitable – for example, seasonal efficiency of boilers and chillers.

Energy model of Keynsham Civic Centre

Once the building is in use, evaluation of the actual energy performance falls into the domain of measurement and verification (M&V). In addition to identifying potential discrepancies between actual operating conditions and design assumptions – for example, changes to occupancy hours of a building – performance evaluations often uncover several technical issues (such as incorrect or inefficient configuration of boilers) that compromise performance in use.

In the absence of a robust M&V framework, however, it is not certain that the technical issues uncovered in a building reflect all, or most, of the key causes of the performance gap. It is likely that one or two key issues are identified during investigations, while other potential issues are not covered. A robust energy performance M&V framework for buildings in use must be able to identify all important issues and separate the following:

- Deviations of the operating conditions from design assumptions that are primarily driven by a building’s function and its actual occupancy, (for example, changes in occupancy numbers and hours, heating and cooling setpoints, and functional use of the spaces)

- Technical issues that cause a performance gap between design intent and actual operation (for example, thermal bypass in the envelope because of missing insulation, inefficient operation of boilers, and lack of detailed commissioning compromising automated lighting control).

An effective M&V framework for evaluation of the performance gap should, therefore, identify deviations in operating conditions and enable users to identify technical issues effectively and comprehensively. CIBSE TM63: Operational performance: building performance modelling, published earlier this year, provides a framework to evaluate the performance in use. The framework proposed in CIBSE TM63 is based on the following principles:

- Use of a systematic method of data collection to identify various discrepancies in operating conditions and potential technical problems when compared against design assumptions and intents.

- Use of a dynamic thermal simulation model of the building, calibrated with actual operation, to drive the process of ensuring that the uncovered issues can explain the actual performance with reasonable accuracy.

- Through the calibration process, two sets of simulation model input data relating to the discrepancies in building performance should be identified and separated:

- (a) Actual operating conditions required for the building to perform its function in practice,

- (b) Technical problems related to construction, system installation, commissioning, control, and so on.

- Once the building performance model is calibrated, a new in-use baseline can be defined for performance that reflects actual operating conditions (adjusted for 3(a) above), but assumes the original design intents are met (issues identified in 3(b) above are addressed in the model to revert to design intents).

- The technical energy performance gap is the difference between actual energy use and the new in-use baseline, defined in Step 4.

This process enables users to define the energy performance gap with reasonable accuracy and avoid the confusions that may arise when performance in use is compared against regulatory calculations, or calculations that do not reflect the actual operating conditions and requirements.

Figure 1: Projection of operational energy use at design stage (TM54), in-use baseline (TM63) and actual energy use for a case study

The process also provides a systematic method for building performance evaluation and helps users identify causes for the performance gap.

The International Performance Measurement and Verification Protocol (IPMVP) can be used for calibration of the building performance models (Step 2, above) – see panel, ‘Using the Performance Measurement and Verification Protocol’.

While the IPMVP and ASHRAE Guideline 14 are structured around calculating savings related to energy conservation measures (ECMs), and to reduce uncertainty in assessing their performance, these M&V protocols can also be followed for other purposes – such as establishing a baseline for performance in use, and monitoring and targeting strategies to improve performance.

CIBSE TM63 provides a step-by-step guide to how such a baseline can be developed to evaluate energy performance in use. It complements CIBSE TM54, which is used at design stage to project operational energy use. The benefits of following a calibration-based approach to evaluate the actual performance of a building and derive a baseline for performance in use are twofold:

- The calibration process provides a systematic approach to building diagnostics and identification of causes of any performance gap.

- The calibration process can help improve the confidence in building performance models, and address potential modelling errors and uncertainties that are often inevitable at design stage. A baseline derived from a calibrated model can, therefore, be a more robust and practical operational target for a building.

Using the performance measurement and verification protocol

The IPMVP is a framework created for measuring and ascertaining performance using best-practice techniques in verification of energy conservation measures (ECMs).

The IPMVP provides guidance on measurement boundary, measurement period, and ways to calculate impact (savings) and undertake operational verification.

Depending on the type of ECM and its relationship with other building performance input or output parameters, the IPMVP provides four options for calculating an ECM’s impact:

- Option A: retrofit isolation, key parameter measurement

- Option B: retrofit isolation, all parameter measurement

- Option C: whole-facility

- Option D: calibrated simulation.

While the first two options look at isolating the assessment and analysis to one or few building systems that are affected by the ECM, the other two are done at a whole-building level. For each of the options, the IPMVP explains the data required and monitoring and measurement protocols. It also suggests ways to undertake accurate calculations and validate results, linking to other relevant standards and protocols.

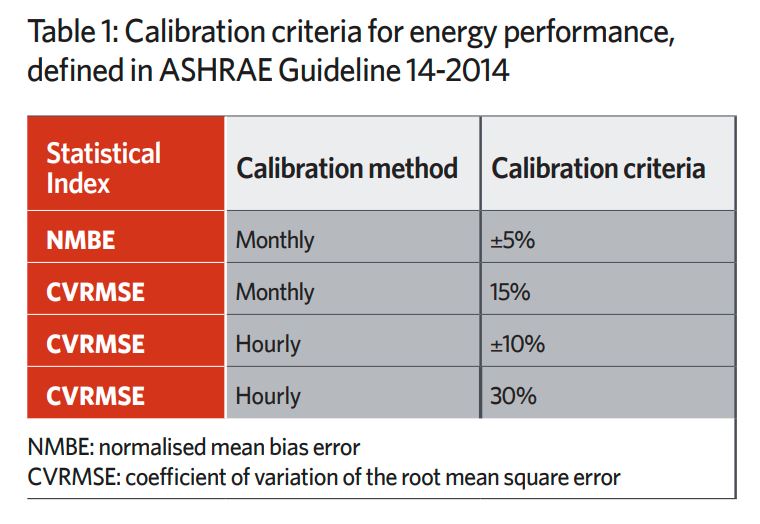

IPMVP Option D, calibrated simulation, suggests using building performance modelling tools for energy consumption and demand simulation, calibrated with hourly or monthly energy data.

The IPMVP framework provides a step-by-step method to fine-tune the model to reflect the building and its operating conditions accurately. It is underpinned by ASHRAE Guideline 14 (Measurement of Energy, Demand and Water Savings), which provides the criteria to check calibration accuracy either at hourly or monthly intervals.

Detailed operational information should be collected during site surveys and by measurements to calibrate the model.

■ Esfand Burman, UCL Institute for Environmental Design and Engineering, and Nishesh Jain, DesignBuilder Software.