Credit: iStock mediaphotos

There is a proven system that, with appropriate integration – and a shift in office-wear norms – could allow comfort cooling with practically zero operational carbon impact.

Mechanical cooling could be replaced in comfort cooling applications worldwide with 120% wet-bulb effective, indirect regenerative evaporative coolers, using 100% healthier outdoor air, recycled water and solar power

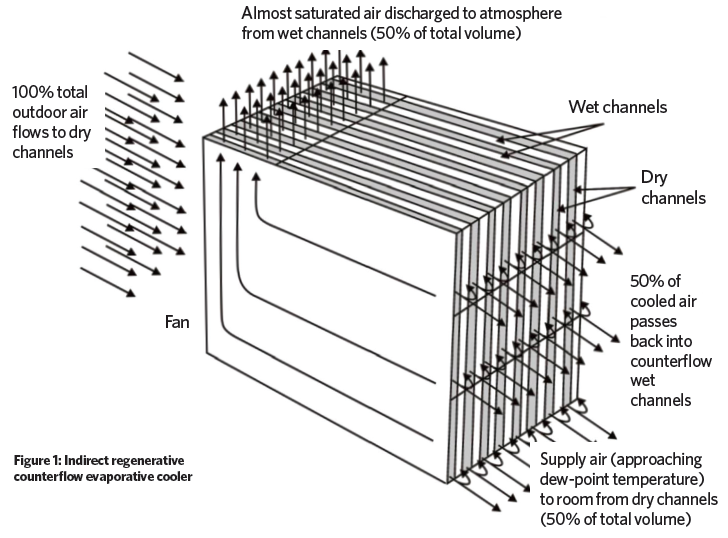

The system is based around the technology of an indirect regenerative counterflow evaporative cooler. The more basic, indirect crossflow evaporative cooler – as shown in ‘Making the case for evaporative’ (CIBSE Journal, June 2017) – is potentially able to drop the air’s dry-bulb temperature 80-90% of the way towards the air’s wet-bulb temperature; this is known as the wet-bulb effectiveness. Typically, with conventional, high-level air distribution, the summer supply air needs further cooling using mechanical refrigeration. However, an indirect, regenerative, counterflow dew-point evaporative unit – originally developed in 1976 by Valeriy Maisotsenko, and shown in Figure 1 – cools the supply air about 35% to 50% more than indirect, crossflow units, and close to the outdoor dew-point temperature, instead of the wet-bulb temperature. It has a wet-bulb effectiveness of about 120%.

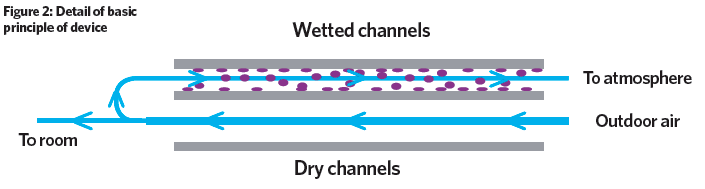

As shown in Figure 2, the regenerative evaporative cooler initially cools a total volume of outdoor air flow towards the air’s wet-bulb temperature. It then returns about 50% of the cooler air – with its lower dry-bulb and wet-bulb temperature – back along a wet, counterflow path. This returned air is saturated by water sprays and wetted surfaces, so reducing its dry-bulb (and wet-bulb) temperature further.

Across the heat exchanger plate, this further cools the incoming total air volume to a lower dry-bulb and wet-bulb temperature. This air leaving the unit (used to supply the room) ultimately nears its dew-point temperature. The remainder of the air, having been saturated in the wetted channel, is rejected to atmosphere. The unit will reach operational steady state within a few seconds of starting.

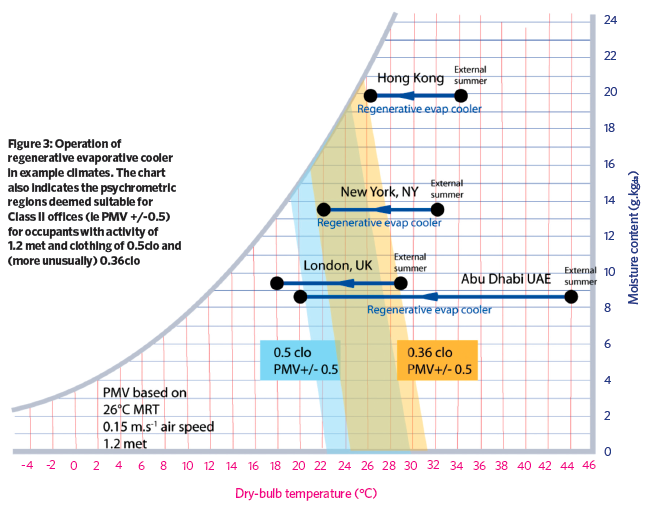

Where buildings are designed to reduce unwanted overheating – and where the outdoor air dew-point design temperature is less than about 20°C – the regenerative evaporative cooler (with no additional mechanical cooling) can meet comfort conditions in many temperate global locations, including west-coast USA, the UK and most European locations, using a conventional, high-level air supply. The system uses slightly less energy than conventional refrigerant cooling; however, a well-designed, low-level air supply system can save even more energy.

At outdoor dew-point temperatures approaching 20°C or above, further refrigeration can still be avoided if a low-level, displacement, air-distribution system is used to supply the air to the space. This can be applied in offices and homes in areas such as New York (peak 0.4% external conditions θao =32°C, DP=19.1°C) with about a 6K supply to room temperature rise (2K in the floor-level mixing air zone and 4K ankle-to-ceiling rise) – particularly when adaptive comfort is considered (see CPD, on page 55).

Displacement systems can also be very effectively applied in locations with lower outdoor air dew-point temperatures (below 20°C), such as London (peak 0.4% external conditions θao=28.2°C, DP=12.6°C). For spaces such as a computer and switching rooms, high room temperature rises, in the order of 10K, can be used. A proportional integral derivative (PID) controller can maintain a constant room temperature by modulating the fan speed, enabling the regenerative evaporative coolers to replace refrigerant-based units in applications where acceptable conditions can be maintained with sensible cooling.

Increased room temperature gradients (as discussed in the Cheong 2005 investigation1) have been found acceptable in tropical climates and, together with adaptive comfort principles, offer opportunities to apply regenerative evaporative coolers in many warmer and humid climes. As reported by Yau2, the standard predicted mean vote (PMV) comfort model – as described in BS EN ISO 7730 and CIBSE Guide A – is not suitable for a hot and humid climate.

So, in sub-tropical and tropical areas, the adaptive comfort model is more important as a method to establish the appropriate internal conditions that are likely to satisfy the thermal comfort requirements of occupants. Effectively, this increases the acceptable temperatures by several degrees beyond the PMV comfort model.

One manufacturer has a range of regenerative, indirect counterflow evaporative coolers, the smallest being an 800 L·s-1 unit requiring 1.4 kW power. This can give 7.5kW cooling in London summer conditions when supplying a room with a design temperature of 26°C. The weatherproofed unit is 2m wide, 2.5m long and 1.5m high, and the operating potential for the same unit in some example climates is shown in Figure 3.

Potential applications for such a unit could be broadened if occupants were encouraged to shift office clothing norms. If people wore lighter-weight clothes in hot conditions, the comfort temperature could be increased by 1.4K. For example, wearing shorts/skirt and a short-sleeved shirt/blouse is 0.36 clo – rather than long trousers and a long-sleeved shirt of 0.61 clo – so the comfort temperature would increase by about 1.4K. Introducing a low-level air velocity of about 0.8m·s-1 could allow a further increase of about 2.6K in comfort temperature. The PMV-related comfort regions have been shown in Figure 3, based on information generated by the CBE Thermal Comfort Tool

Just changing the clothing allows for a higher room temperature (of +1.4K) and extends the use of regenerative evaporative coolers as the sole provider of cooling in applications such as New York.

Based on data from the EC Photovoltaic Geographical Information System, the 1.4kW unit (providing 7.5kW cooling in London) could be powered by a 14m2 solar PV array – so cutting the demand on the electrical supply network and reducing the operational environmental impact.

Recycled, collected or even wholesome water can be used to provide the cooling, which is then evaporated into the atmosphere with no atmospheric degradation. A regenerative evaporative cooling system uses less water per square metre conditioned area than that evaporated by cooling towers in water-cooled air conditioning systems.

Comparing the coefficient of performance of evaporative coolers with that of standardised refrigeration units is not comparing similar devices or environments. It is better to compare the total seasonal energy use of devices operating in the same area under similar conditions.

John Hammond MCIBSE

References:

- Cheong KKWD et al, Thermal comfort study on vertical air temperature gradient with displacement ventilation system in the tropics, Indoor Air, 2005.

- Yau YH et al, A review on predicted mean vote and adaptive thermal comfort models, BSER&T, Vol 35(1) 23–35, CIBSE 2014.