The complexity of calculating the embodied carbon of façade systems should not be underestimated

The UK’s goal of reducing net emissions of greenhouse gases by 100% by 2050 (relative to 1990) has prompted industries and organisations to set carbon reduction targets to reduce emissions. To quantify the operational and embodied carbon of buildings and infrastructure accurately, life-cycle assessments (LCA) calculations are required. Furthermore, with reductions in operational carbon in construction because of changes to legislation and the decarbonisation of the energy Grid, embodied carbon now forms a greater percentage of emissions associated with buildings. Consequently, it requires more detailed quantification to better understand emissions and how they can be reduced.

European standards BS EN 15978 and BS EN 15804 provide guidance on the assessment of the environmental impacts of buildings, but further interpretation is often required to apply these principles in practice. Several industry bodies have provided further guidance to aid clarification and promote adoption. These guides typically relate to specific disciplines and building elements, including the primary structure IStructE guide How to calculate embodied carbon, and Embodied carbon in building services: A calculation methodology CIBSE TM65.

While the façade accounts for between 10% and 31% of the embodied carbon of a building, according to studies by the World Business Council for Sustainable Development1, there is currently no aligned method for how façade embodied carbon is to be calculated.

Stone cladding may have low embodied energy, but the façade subframe can add large amounts of embodied carbon

Complexity

Calculating the embodied carbon of façade systems requires a detailed understanding and awareness of the many components and processes that can vary widely between different system assembly life-cycles and project scenarios. Assessors who are not experienced in façades can inadvertently make inaccurate assumptions or omissions relating to a component and system life-cycles, which may fail to account for system differences and requirements that can have a large influence on the total embodied carbon of the façade. Inaccurately reporting the façade’s embodied carbon will have consequences when, for example, comparing different construction strategies across multiple building elements to optimise the overall emissions of the building.

As an example of how façade complexity can often be underestimated in embodied carbon calculations, consider a rainscreen cladding system comprising natural stone panels. The stone panels have a low associated embodied carbon factor when only considering the natural stone material during the product stage. However, the metal subframe required to support the stone and the additional components and processes necessary for the system to achieve the required level of performance can add a large additional amount of embodied carbon.

Changes in environmental loadings – for example, wind load, external temperatures, and corrosivity – in various geographic locations also influence façade system requirements, where more materials and/or processes may be required to accommodate project-specific loads and environmental conditions. Additionally, the durability and service life of façade materials and system components could necessitate enhanced maintenance requirements, or the replacement of failed systems multiple times over the lifetime of a building.

Assessors who are not experienced in façades can inadvertently make inaccurate assumptions oromissions

Glazed systems are an example of this; a fully-glazed curtain wall, including insulated glazing units (IGU), could require IGUs to start being replaced around the 25-year mark when failures drive the demand.

Masonry or precast concrete façades, including openings with IGUs, would similarly require replacement of IGUs within the lifetime of the building. The masonry or precast concrete included in the wall could last 60 years or more, however, which would reduce the material quantities required for replacement during the life of the building.

All of this and more must be considered in the calculation of a façade’s embodied carbon to achieve more accurate assessments that will contribute to identifying the most effective carbon-reduction strategies in façade life-cycles, as well as more precise inputting into larger, whole-building LCAs.

Consultants and contractors specialised in façades have started addressing this need, with efforts made to assess the embodied carbon of façade systems on their projects, to provide guidance and inform whole-building LCAs by sustainability consultants.

Consistency

While efforts by the industry to quantify the embodied carbon of their designs is a much-needed step in the right direction, a critical prerequisite is missing from this effort – LCA consistency. Without a consistent methodology for façades to interpret the general LCA framework set out in BS 15978:2011,2 different approaches will be taken, so causing inconsistencies.

Comparing existing life-cycles assessment methods

To compare life-cycle assessment methods, six façade consultants and contractors carried out an LCA on a case study façade.

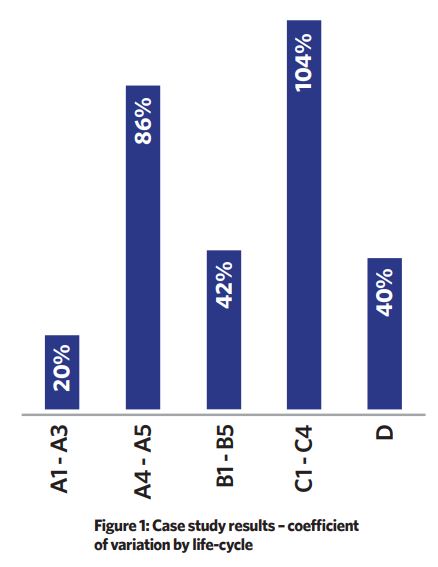

There was a significant variance in results across all life-cycle stages (A-D), otherwise known as cradle to cradle3. Results varied by approximately 20% in the A1-A3 stage, and this further increased in stages B, C and D because of the greater level of uncertainty and inconsistency over how these stages should be assessed for façades (see Figure 1).

A large contributing factor to this variation was because of differences about which façade components were included and how they were considered in the calculations, as well as the lack of a consistent approach on what embodied carbon factors to use in calculations and where to source this data from. In some cases, individuals in the case study group developed their own embodied carbon factors for IGUs, and replacement factors by extrapolating available manufacture data. However, this was not guided by a specific process to allow for consistency.

The case study also showed that façade emissions beyond the product stage can be a significant contributor to total emissions, ultimately requiring stages such as (A4) transportation, (A5) construction, and (B4) replacement, more specifically, to be included as a minimum from the outset.

The main conclusions from this case study are summarised as follows:

- A defined method for calculations and assumptions are required for façade LCAs

- Consistency is required over what façade components must be included in LCAs

- Guidance is required on how to derive and apply embodied carbon data in façade LCAs

- The significance of developing an approach to calculating life-cycle stages beyond A1-A3 for façades must not be overlooked.

Following the formation of a sustainability committee and the publication of its first guidance paper, the Centre for Window and Cladding Technology (CWCT) established a further workstream to focus on producing an embodied carbon methodology for façades.

The group, consisting of six UK façade consultants and contractors, first used methods and tools from their respective companies to carry out an LCA on a case study façade. The outcome would be crucial in revealing the work needed to produce a consistent methodology. When results were compared, they revealed a significant variance across all life-cycle stages (A-D). See panel, ‘Comparing existing life-cycles assessment methods for facades’.

The case study provided the catalyst for the group’s next task, which was to develop an embodied carbon calculation methodology dedicated to façades, ultimately to bring consistency and accuracy to façade LCAs. This is just the first step in a much larger plan,2 which will require implementation of the methodology by the industry so that we can establish a clear picture of how different façade systems and strategies compare with regard to embodied carbon. Most importantly, it will help show how we can reduce embodied carbon by setting targets and having more reliable data available.

The methodology was developed with input from manufacturers, contractors and consultants in the UK and throughout Europe

The draft CWCT methodology is currently undergoing peer review by a group of industry members, including the main developers of the widely used methodologies for other building elements, such as the IStructE and CIBSE guides.

The methodology was developed with input and collaboration from manufacturers, contractors and consultants working in the façade industry, primarily in the UK, but also throughout Europe. It aims to address inconsistencies identified in the case study while ensuring alignment with standards such as BS EN 15978 and the RICS Professional Statement, including its interpretation for façade LCAs.

The CWCT considers this to be a document that will be updated to reflect the most recent knowledge and developments in the field of whole life carbon assessment of façades. The methodology is anticipated to be released to the wider public in autumn 2022.

More Information

For more CWCT guidance on sustainability, reducing carbon, environmental product declarations, and life-cycle modules, visit www.cwct.co.uk

Teni Ladipo is senior façade consultant at BuroHappold

References:

1 Net zero buildings: where do we stand? World Business Council for Sustainable Development, 2021.

2 BS EN 15978:2011 Sustainability of construction works. Assessment of environmental performance of buildings. Calculation method.

3. LETI Embodied Carbon Primer, Jan 2020, Bit.ly/CJJul22TL1