The Grenfell Tower disaster, the tenth anniversary of which will be marked next year, has created an unprecedented focus on fire-prevention issues.

Advanced Air has conducted a wide-ranging survey of CIBSE Journal readers to find out the level of understanding and approach to fire and smoke damper specification and standards among building services engineers.

Perhaps unsurprisingly, the survey shows that compliance with Building Regulations and fire performance are uppermost in the minds of building services engineers when selecting fire and smoke dampers. Of those who responded to the survey, 83.8% said compliance with Building Regulations is ‘crucial’. Nearly as many (82.6%) described fire performance as ‘crucial’.

This was much more than the 45.9% who gave the same weight to installation flexibility in terms of compatibility with various wall or ceiling types – and barely a quarter said whole life cost or maintenance access are crucial.

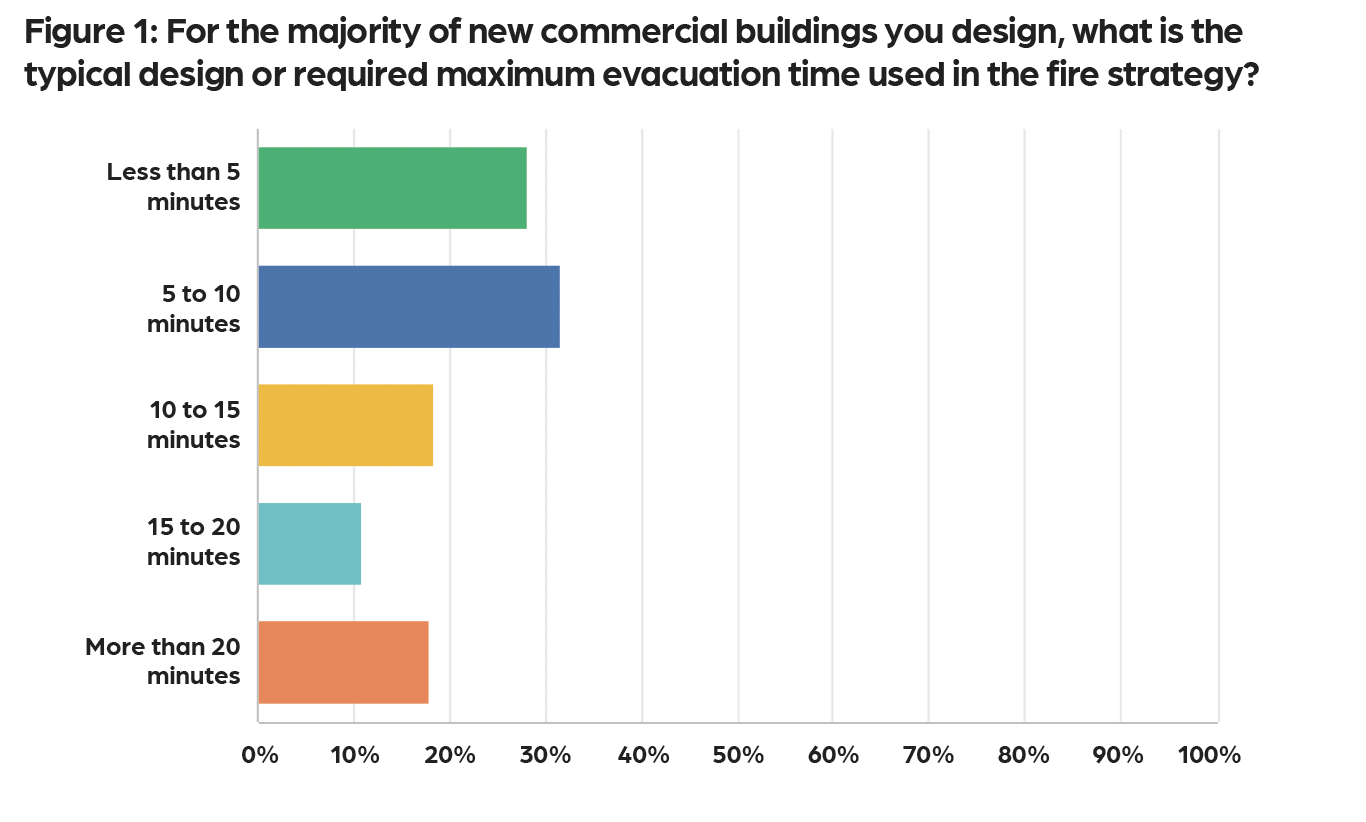

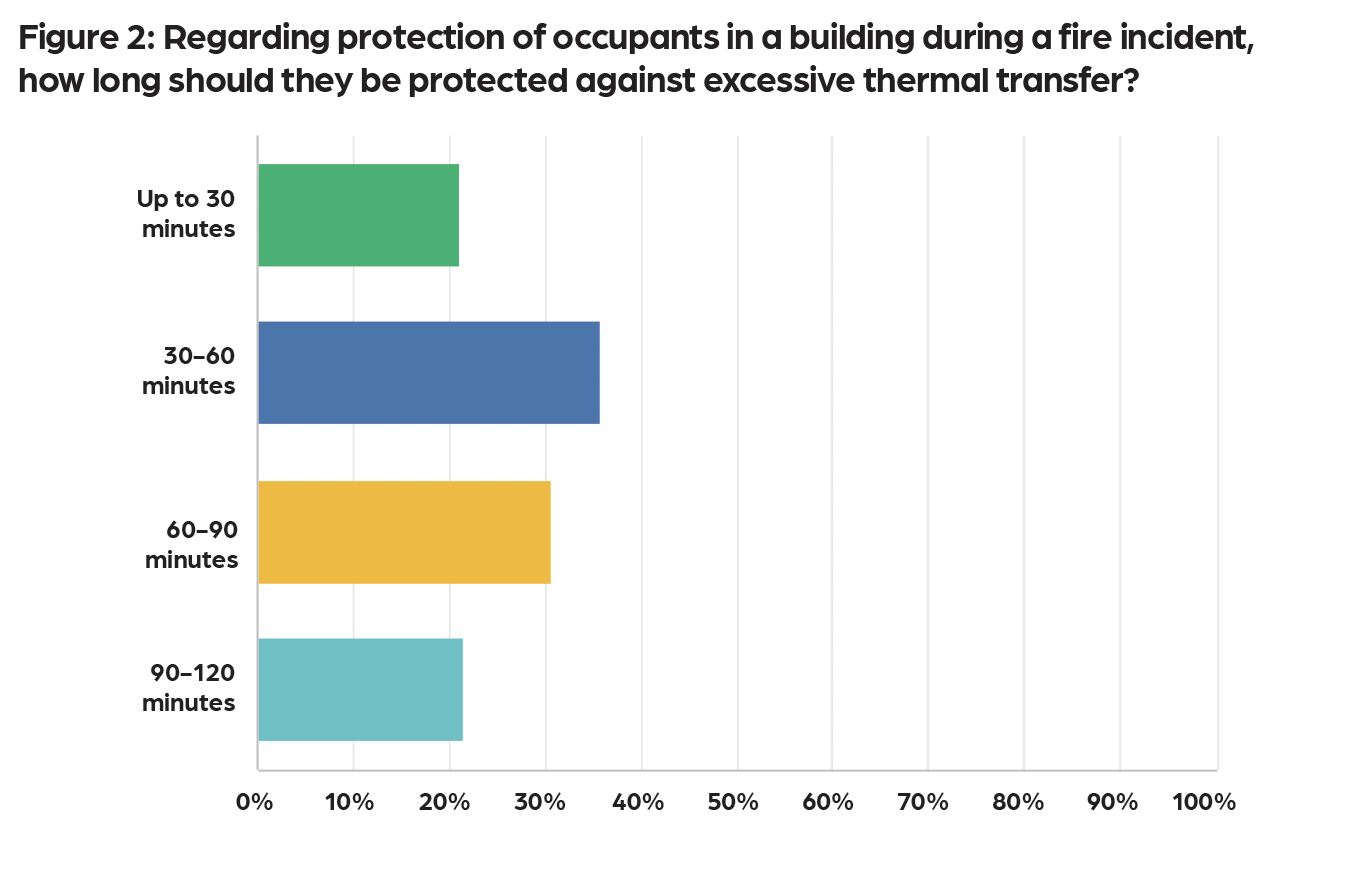

Advanced Air then asked respondents about the typical design or required maximum evacuation time they use in fire strategies for the majority new commercial buildings they design (Figure 1). Respondents were also asked how long occupants in a building should be protected against excessive thermal transfer during a fire incident (Figure 2).

Thermal transfer refers to the heat that passes through a damper during a fire. Fire-resistance tests measure both integrity (preventing flames and hot gases passing through) and insulation (limiting heat transfer and therefore the temperature rise on the protected side). A rating such as EI 60 means the damper has been tested to maintain both of these properties for 60 minutes, preventing flame spread and keeping the unexposed surface below the temperature limits defined in the standard fire-test procedures.

Andrew Sargent, general manager at Advanced Air, believes there is a mismatch between the responses to these two questions. ‘It’s a bit disjointed,’ he says, pointing out that the required maximum evacuation time respondents are using in fire strategies is much lower than the length of time they believe occupants of a building should be protected against excessive thermal transfer. However, Dwyer says there may be no correlation unless individuals who responded with lower maximum evacuation times also responded with longer protection against excessive thermal transfer.

The responses on required maximum evacuation times being used in fire strategies is ‘pretty much in line’ with what Sargent would expect, but he is surprised about the 18% figure for those factoring in more than 20 minutes to their fire strategies’ typical design or required maximum evacuation times.

‘Most people would be out of the building within about 10 to 15 minutes at max. If most people are going to be out of the building, why would they want the products to protect against thermal transfer for 90 to 120 minutes?’ he asks, adding that the mismatch in responses could be a ‘lack of understanding’ about the nature of thermal transfer. Dwyer says other reasons could be design-side conservatism, different project types and insurer requirements.

We want to give the consultants the best information they can have

‘We’ve done tests and we want to educate people on what the temperatures really are,’ says Sargent. ‘There is a great deal of caution among consultant engineers at the moment regarding thermal transfer.’

‘Many projects are now taking an increasingly belt-and-braces approach, which can add unnecessary cost in some situations. With clearer information and a better understanding of the underlying thermal-transfer issues, engineers can make more proportionate and well-informed design decisions.’

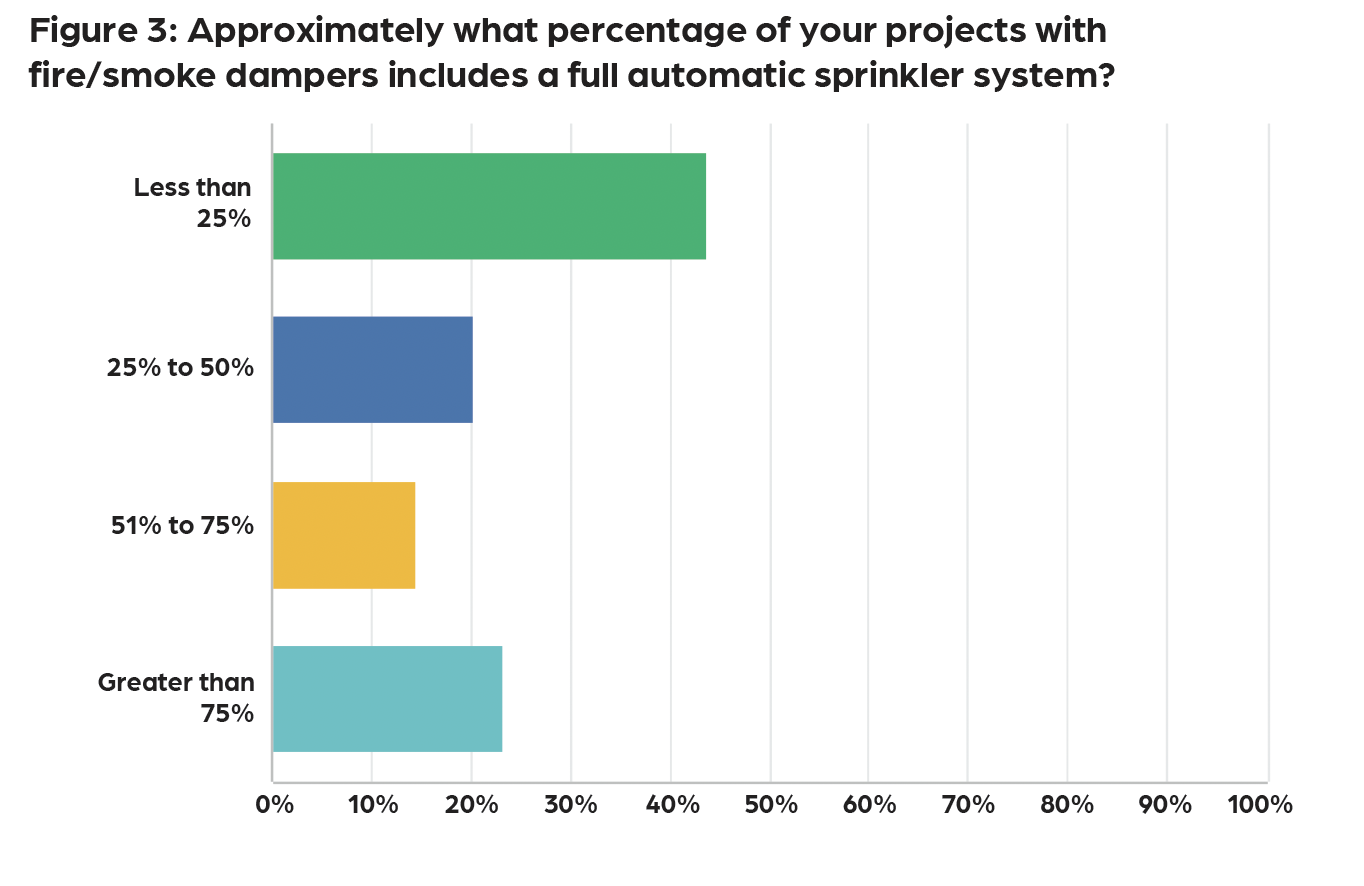

Asked approximately what percentage of their projects with fire or smoke dampers include a full automatic sprinkler system, 43.6% said less than a quarter. However, fire protection campaigners will be more reassured to find a much bigger proportion (23.3%) said more than three-quarters.

The proportion of projects with fully automatic sprinkler systems isn’t as high as Sargent expected, however. Dwyer agrees

given the increased attention on fire-safety measures in recent years and the growing emphasis on active fire-protection systems in commercial developments.

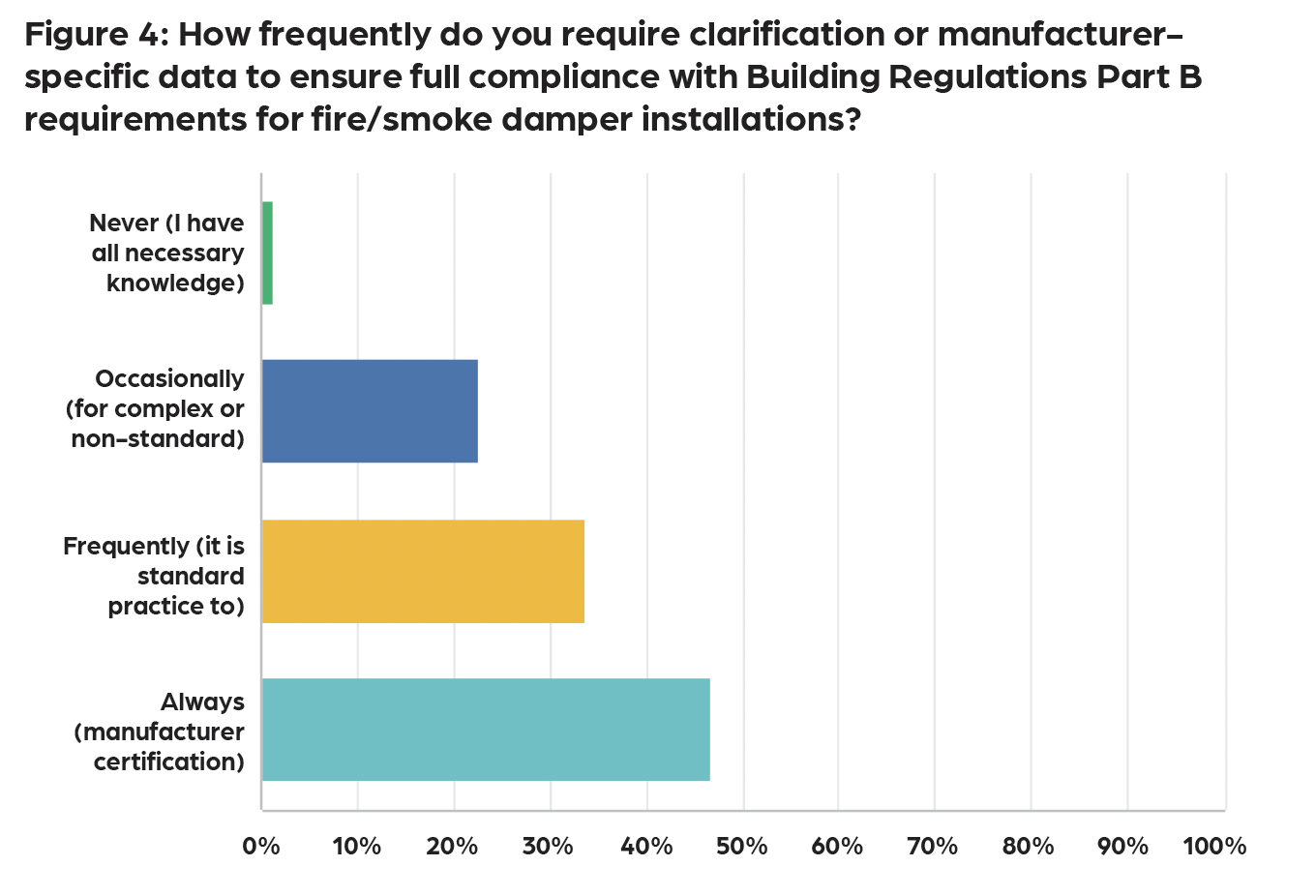

In response to how frequently they require clarification or manufacturer-specific data to ensure full compliance with Building Regulations Part B requirements for fire or smoke damper installation, 1.3% said ‘never’, indicating they believe they have all the necessary knowledge.

This minority of respondents was far outnumbered by the 46.7% who say they ‘always’ do so because manufacturer certification or documentation is their primary check. In between were the third (33.6%) who replied ‘frequently’ because it is standard practice to rely on manufacturer data or training, and the 22.7% who said they ‘occasionally’ require clarification or manufacturer-specific data for complex or non-standard applications.

Quizzed on interpreting the fire damper classification markings based on the testing requirements of BS EN 1366-2, as stated in BS EN 13501-3, 15.7% and 49.8% said they were ‘highly’ and ’moderately’ confident respectively about doing so – but more than a third (36.2%), said they needed further guidance.

Respondents were less confident about interpreting the smoke control damper classification markings based on the testing requirements of BS EN 1366-10, as stated in BS EN 13501-4.

Around one in eight (13.8 %) said they are ‘highly’ confident and just less than a half (47.8%) were ‘moderately’ confident. This was only slightly higher than the 41.15% who expressed a need for further guidance or training.

Any lack of understanding is likely to stem from where respondents get their information, Sargent says. ‘We have to get more information to consultants, so when they are making their decisions, it’s based on the facts and the best information.

‘We’re not here to tell anybody what to do. We want to give the consultants the best information they can have when they’re making their decisions.’