The Ravelin Sports Centre in Portsmouth won a CIBSE Building Performance Award

The University of Portsmouth’s Ravelin Sports Centre is setting new standards for low-energy design. Leisure centres are often associated with high energy use, but with an energy use intensity (EUI) of just 87kWh·m-2 per year, this pioneering facility uses one-tenth of the energy of a typical centre, saving the university more than £800,000 on its annual energy bill.

It won Project of the Year – Leisure at the 2024 CIBSE Building Performance Awards with judges impressed by its careful, low carbon design and application of technology.

What’s more, the performance data has been used as an exemplar case study by the UK Net Zero Carbon Buildings Standard, to help establish a best-practice benchmark for operational and embodied carbon for future leisure centre buildings.

Carbon

Target annual energy use: 218kWh/m2GIA/yr

Actual metered energy use: 87kWh/m2GIA/yr

Reliance on fossil fuels: No

Onsite renewable energy systems: 1,000m2 photovoltaic installation design output: 207MWh/yr (20% of building energy demand) measured output after 1yr: ~215MWh/yr

To achieve this remarkable feat, building services engineers Max Fordham – working with architects FaulknerBrowns, the client and main contractor – have taken every design decision as an opportunity to minimise energy consumption further.

As such, the building incorporates a range of passive and active environmental technologies, including the extensive use of daylight and mixed-mode ventilation. In addition, heat is provided by air source heat pumps (ASHPs) incorporating load-shedding controls, while the complex is crowned by a giant biosolar roof that provides up to 20% of the building’s electricity needs.

The £57m sport centre’s low-energy design is a response to the university’s campus energy and sustainability masterplan. Developed by Max Fordham under a previous project, the masterplan includes a requirement for all new buildings to achieve Breeam Outstanding and a Display Energy Certificate (DEC) ‘A’ rating in operation.

Large rectangular rooflights supplement daylight in the pool area

To achieve DEC ‘A’, the design had to target a maximum EUI of 218kWh·m-2 per year. Ambitiously, Max Fordham set out to meet this already challenging target without the use of fossil fuels. ‘When we started to develop the design in 2016, gas boilers were the standard solution, but we said “this building is not going to complete until 2022, when Grid carbon will be lower, so we should not be basing our design on fossil fuels”,’ says Mark Palmer, director and sports leader at Max Fordham. Opting for an all-electric solution would also ensure the building’s carbon emissions fall further as the Grid continues to decarbonise.

Minimising embodied carbon

Alongside operational carbon, embodied carbon was targeted at RIBA Stage 3 to minimise the sports centre’s whole life carbon.

This was undertaken before the publication of CIBSE TM65, so the focus was on reducing the building footprint and refining the building structure, where most of the embodied carbon was concentrated. The building’s concrete basement car park box – which Palmer describes as ‘the biggest single contributor to embodied carbon’ – was an unfortunate planning requirement.

Key design changes to the structure included the use of ground-granulated blast-furnace slag binder in the concrete basement construction, and changing the basement retaining wall construction from one based on a continuous flight auger-pile wall to a much slimmer retaining wall, constructed using temporary sheet piling.

Interestingly, Palmer says the green roof marginally increased the scheme’s embodied carbon because of the larger steelwork frame required to support the roof’s additional weight. However, he says this has to be considered in the context of the roof’s other benefits, such as helping attenuate rainwater run-off and increasing biodiversity

The university’s brief to the design team was for a sports centre with a 25m swimming pool, an eight-court sports hall, 175-station fitness suite, climbing wall, ski simulator, and fitness studios, along with offices and teaching spaces.

Palmer says the starting point in developing the building’s form was to separate the swimming pool from the ‘dry’ areas (the sports hall, fitness suite, and so on), so that the circulation space between can form an environmental buffer zone.

Unusually, the design places the sports hall on top of the ground-floor fitness suite and changing rooms. ‘One of the key decisions was to put the sports hall on the first floor, to ensure that it and the swimming pool could benefit from rooflights, to provide passive heating and daylight, which saves energy and is good for wellbeing,’ says Palmer.

One of the striking giant fans set into the ceiling in the gym. The fans have been designed to generate air movement to reduce the need to drive down the fitness suite air temperature

Flexibility is key to keeping the building’s footprint and embodied energy to a minimum. The swimming pool, for example, has a floating floor, to do away with the need for a learner pool; the squash courts are separated by a moveable partition to enable them to be converted into additional studio space; and the studio spaces incorporate a moveable partition that allow them to flex to accommodate a variety of class sizes and activities. The compact building’s high-performance envelope has been kept deliberately simple to avoid complex junctions and cold bridges.

In addition, the swimming pool envelope has been fortified with additional insulation, to deal with the higher air temperature and humidity in the space. Employing a simple, system-build envelope solution made it easier to build and, Palmer says, gave contractor Wates Construction ‘a fighting chance of delivering on the design airtightness and thermal performance in practice’.

The rooflights in the sports hall and swimming pool are designed to open. They are arranged in strips in the sports hall, strategically positioned between the badminton courts to allow daylight in while minimising the impact of glare on the players.

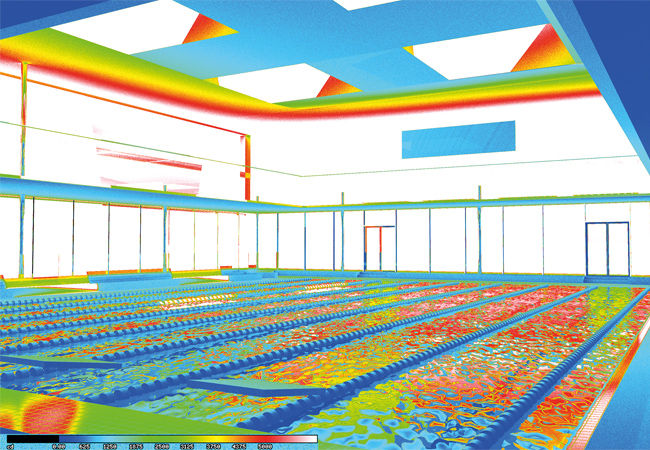

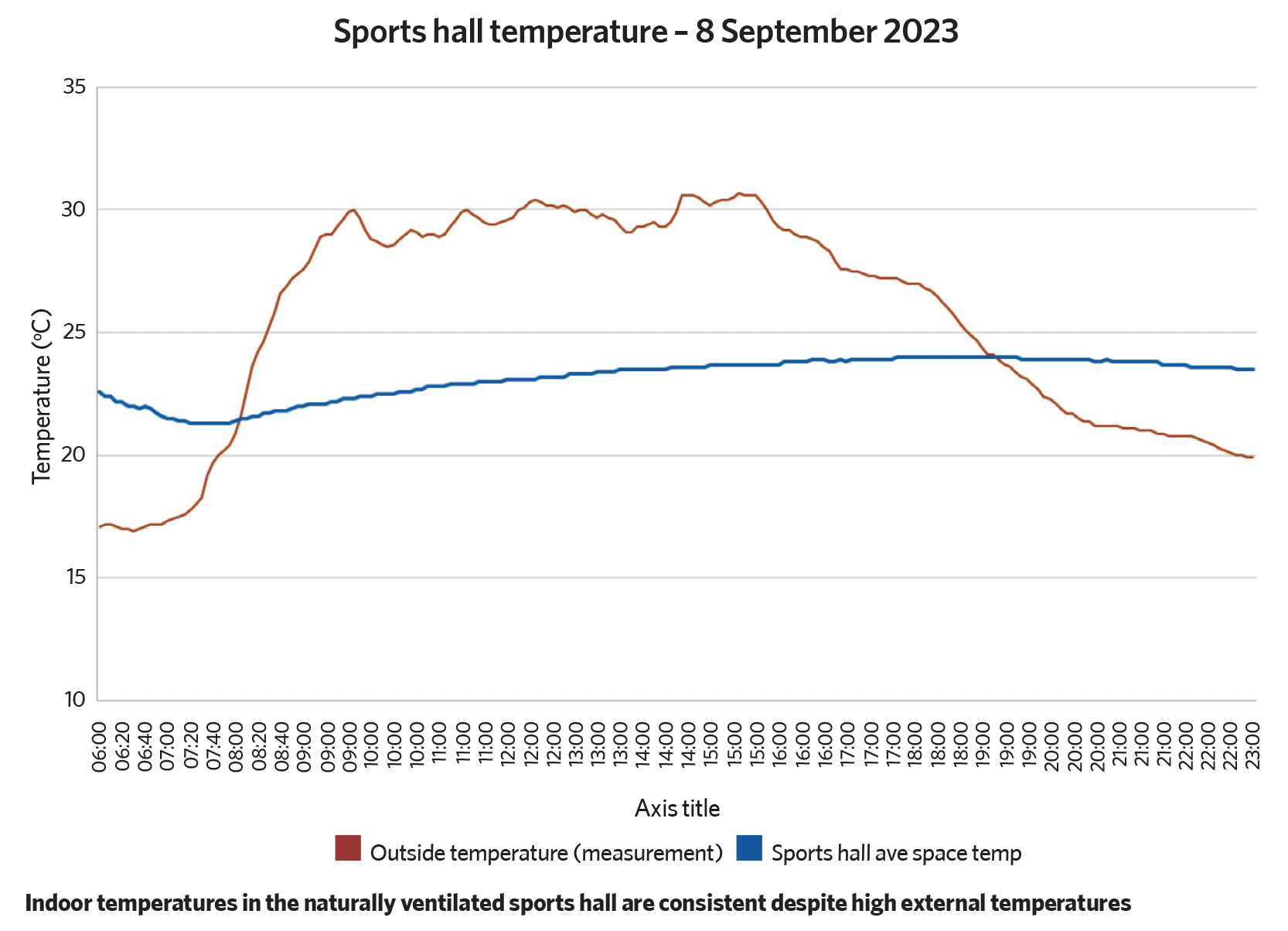

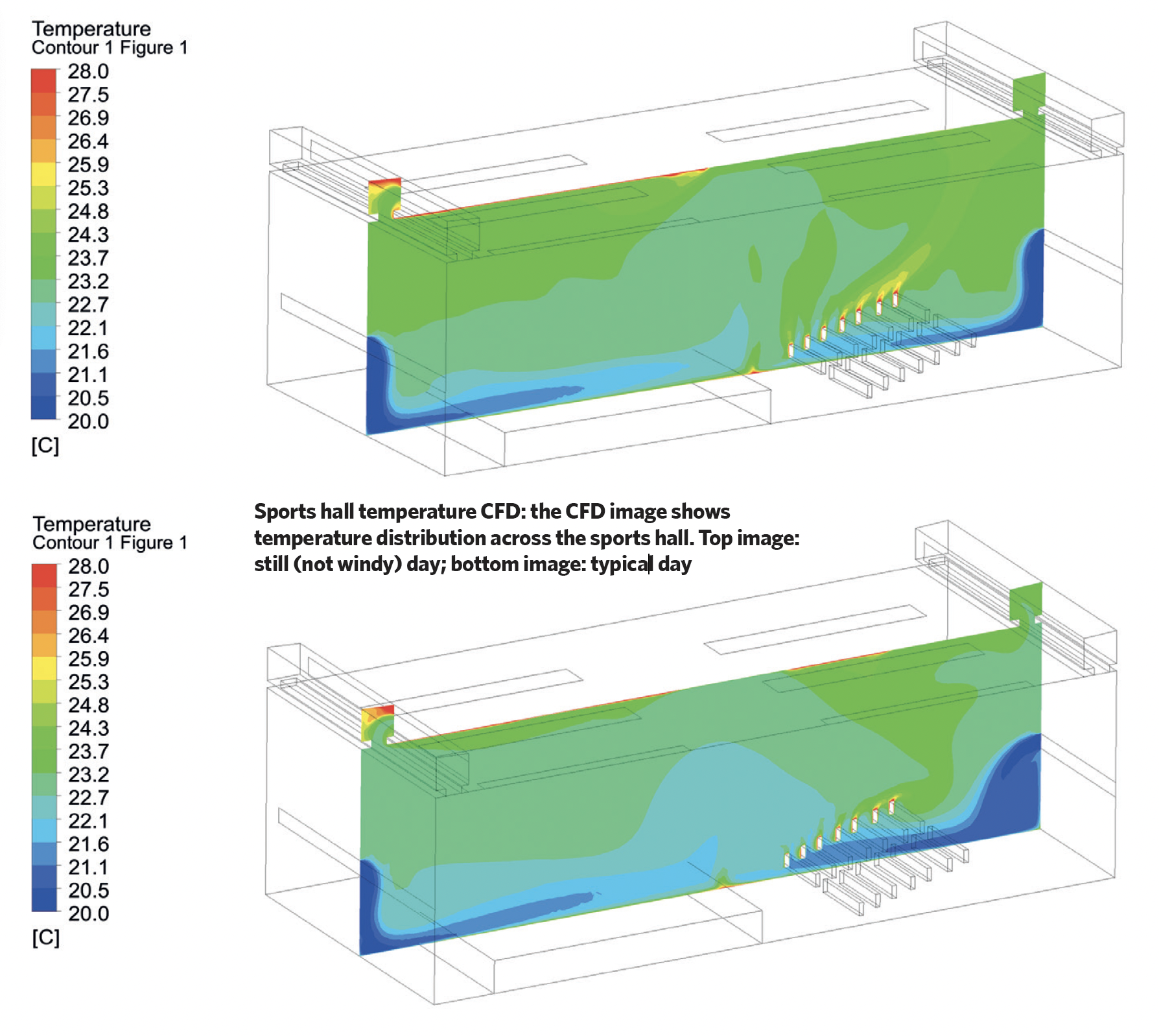

In the swimming pool, four large, rectangular rooflights supplement daylight from the full-height glazing on the north and east elevations that allow views out over the surrounding parkland. The impact of daylight was analysed for the pool to ensure glare and reflections from the water surface would not impede the lifeguards’ views of swimmers on and below the surface of the water. For the majority of the year, the pool hall rooflights remain closed, Palmer says, to provide ‘free heat and light’ – but, on hot days, they can be opened, along with intermediate-level ventilation dampers. ‘The space operates more like an outdoor pool on a hot day, so we can turn off the heating, ventilation and lighting,’ explains Palmer. When the temperature drops, the rooflights close and the space reverts to mechanical ventilation with heat recovery to maintain occupant comfort. In the sports hall, conditions are maintained year-round using a natural ventilation solution. Here, outside air is introduced through a ‘generous area of opening louvres’ midway up opposing walls, to ensure air movement does not affect the flight of badminton shuttlecocks. Driven by stack-effect ventilation, air exits through the rooflights. Palmer says: ‘Our light and air modelling team undertook computational fluid dynamics (CFD) analysis for all the hall’s activity scenarios, from badminton games through to a basketball competition watched by 250 spectators.’Open-minded

Max Fordham has eschewed natural ventilation for an innovative cooling and mechanical ventilation solution for the intensively used, 175-station fitness suite. Alongside a conventional fan coil cooling system, a series of large-diameter, high-volume, low-speed horizontal fans have been recessed into the ceiling, like the slowly spinning rotor blades on a series of upturned helicopters. These giant fans have been designed to generate air movement to reduce the need to drive down the fitness suite air temperature. The large fans are supplemented by 13 smaller fans concealed above the ceiling.

The conventional way to deliver comfort to a fitness suite is to lower the air temperature to help people lose heat. Sport England’s guidance, for example, suggests maintaining temperatures as low as 16°C-18°C. But Palmer says this can result in ‘very high energy use’ that often ‘fails to deliver occupant comfort’ because, when we are sedentary, radiation is the primary mechanism of heat exchange. As exercise intensity increases, however, convection and, eventually, the evaporation of sweat become the dominant modes of user heat loss. ‘If the air in a gym is cool, still and humid, your sweat is unable to evaporate to cool you down,’ Palmer explains.

For those undertaking high-intensity exercise, convective and evaporative transfer of body heat are increased significantly by air movement. ‘By creating air movement and controlling humidity, we are able to achieve much better levels of comfort at temperatures that are not as cold,’ Palmer adds. See ‘Fit for purpose’, CIBSE Journal October 2018 for more on this bit.ly/CJRav.

In addition to the giant fans, four-pipe fan coil units (FCUs) have been tucked out of sight above the suite’s slatted wood ceiling. The FCUs provide the space with heating and mechanical cooling. ‘The client was a bit nervous about the effectiveness of our giant fan solution, so the fan coil units have been sized to cool the space conventionally without the need to run the fans,’ says Palmer, who adds that the client need not have worried. ‘Everyone loves this solution: it’s striking to look at and it’s proven to be very effective.’

In addition to ensuring the university’s management and operations teams have a good understanding of the building and its systems, soft landings enabled the engineers to tweak the fan system once the fitness suite was fully operational. They estimate that increasing air movement in the fitness suite, as opposed to relying on a lower temperature setpoint, will result in a 10% reduction in energy use in peak summer conditions.

Heat for the building is supplied by five ASHPs via a low-temperature buffer vessel. To maximise ASHP efficiency, heating is at 45°C flow/40°C return, which, Palmer says, is ‘quite challenging when we need to heat the pool hall to 30°C. To operate the system at these low temperatures relies on high levels of heat recovery and a high-performance building envelope’. The solution also required non-standard fan coils, air handling unit coils and heat exchangers to exploit the low flow temperatures.

Reducing glare

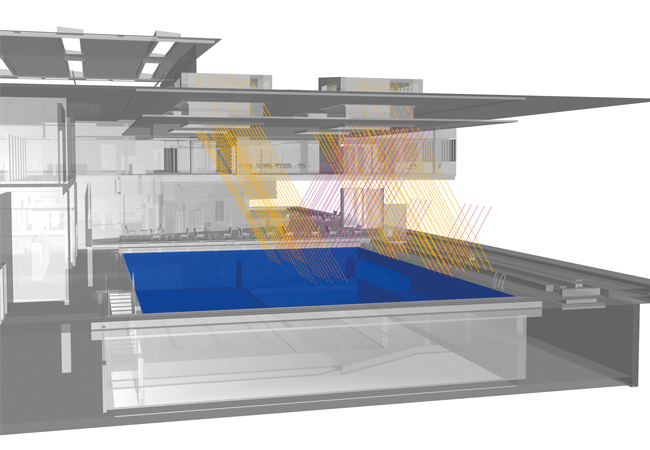

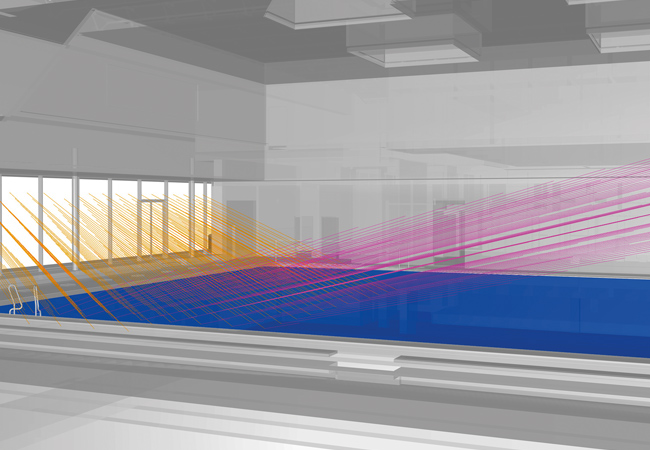

Plots show the direct sun penetration at two points during the year. These simulations are conducted using a bespoke tool, Beam Tracer, created by Max Fordham to calculate specular reflections. Orange represents the direct sun transmitted through the glazing; pink is the reflection from the pool surface. As a result of the steep-angle reflections from direct sun through the top, lights remain at high level and do not enter the occupied zone, where they can cause glare. At low sun angles, some direct sun penetrates into the pool area and can cause glare to occupants. By carefully mapping the path of the sun, lifeguards can be positioned to avoid areas that experience glare from direct sun.

The ASHPs incorporate load-shedding controls to minimise peak heat loads and reduce their size, capital cost and embodied energy. Palmer says minimising heat loads, maximising heat recovery and using load shedding ‘has allowed us to squeeze the combined capacity of the heat pumps down to 525kW, around a quarter the capacity of boilers in a typical leisure centre’. This ensured the heat pump solution was space-efficient and economically viable.

The pool water heat exchanger, for example, has a heat demand of 500kW, which, under the usual control regime, would take up the full heat capacity of the ASHPs, leaving nothing for space and water heating. However, Palmer says the only time it needs to deliver this output is when it is heating the pool water up from cold.

For the majority of the time, the heat exchanger is only required to output about 50kW to maintain the water at a steady temperature – and because the pool water acts like a huge thermal battery, the system can wait until the demand for heat is lower. ‘We put a lot of work into ensuring the heat pumps are not oversized, because it would have been easy to think we needed four times as many heat pumps. But if you are in control of where the heat is going, it allows you to shed some of the loads,’ Palmer explains.

Two additional water source heat pumps are used to raise the water temperature from 45°C to 60°C to supply the hot water calorifiers.

In addition to the five heat pumps dedicated to heating, the sports centre has five, four-pipe heat pump chillers optimised to provide cooling, but which can also provide free heat to the building. These supply the FCUs with chilled water at 6°C/12°C. The units can simultaneously top up the thermal store using heat reclaimed from the cooling side. The heat generated by activity in the fitness suite and dance studios is captured and used to keep the pool warm and preheat hot water for the showers, explains Palmer.

There is a heat recovery unit on the pool water filter backwash system, too. The backwash is used to clean the water filters. In addition, to maintain pool water quality, 30 litres of water is added to the pool per bather, with a corresponding amount removed. This water is used to flush the centre’s toilets.

Engineering the sports centre’s low-energy design was ‘the easy bit’, says Palmer, who adds that it is often the execution, rather than the design, that prevents schemes from achieving predicted energy performance. For Ravelin, Max Fordham was novated to Wates Construction under the two-stage design and build contract, and appointed by Wates Building Services to develop its installation and record drawings in Revit. The engineer also worked with Wates’ offsite manufacturer, Prism, to integrate prefabricated service modules and plant skids. ‘It meant we were able to take responsibility for the design from concept to installation,’ says Palmer.

Max Fordham also produced drawings for the client, with all CoBie asset information, as a full BIM project. Palmer is complimentary about how Wates Building Services (now SES) tackled the project. A two-stage procurement route ensured the contractor was able to price ‘every bit of kit specified, to avoid compromises with lower-efficiency alternatives’. Execution was also helped by the soft landings specification insisting that Wates appoint an independent commissioning manager (Banyards). Its task was no doubt helped by the building having more than 200 electricity and heat meters. ‘At completion, the building was properly and fully commissioned so that it performed well from the get-go,’ says Palmer.

Post-occupancy, the soft landings initiative requires Max Fordham to monitor the building and report each month on how the various spaces are performing – a task aided by the engineer having remote access to the BMS and meters.

There were also monthly meetings to gather client feedback. Palmer says: ‘If something was not working, it was raised at the meeting so that, by the next meeting, it had been resolved, which helped ensure the client never lost faith in the design and remained engaged in the low-energy strategy.’

A major challenge with sports buildings is the huge variation in occupancy throughout the day. In the evening, they are usually full and everything is running flat out, whereas, in the middle of the day, they are relatively empty. ‘M&E designs often only focus on meeting peak conditions and do not consider the other times when occupancy drops off,’ explains Palmer. ‘But you have some pretty powerful kit in this building, so you will waste a lot of energy if you don’t turn things down or off when occupancy drops.’

One issue raised post-occupancy was the level of local control that users should be given, particularly over the temperature of the fitness studios after complaints that these were either too hot or too cold.

Post-occupancy evaluation monitoring showed the rooms were performing as designed, with temperatures being maintained at 18°C, and CO2 levels rising and falling, and the fresh air fans responding accordingly, depending on occupancy. After questioning users throughout the day, however, it became clear that when the spaces were used for high-intensity exercise classes, users found them to be too hot, whereas when they were used for a zen yoga class, for example, users were too cold. ‘We’ve now added a button to each studio to allow the temperature to be changed up or down a couple of degrees for an hour,’ says Palmer.

This approach has clearly worked, and highlights the benefits of a soft landings approach. Perhaps more impressive is that the scheme improved significantly on the original, challenging EUI target of 218kWh·m-2 per year.