It is essential for engineers and designers to have an accurate estimation of peak water demand in buildings, to design proper water-supply systems, storage tanks, boilers and booster pumps.

Previous studies have shown that the amount of drinking water used in buildings has reduced significantly as a result of a considerable change in water efficiency and user behaviour. Despite this, however, traditional design approaches are still used for determining design flow rate; which results in overestimation of water demand.

In recent research, the focus has been on residential buildings – for example, the Loading Units Normalisation Assessment (Luna) project between CIBSE, the Chartered Institute of Plumbing and Heating Engineering (CIPHE) and Heriot-Watt University is looking at the most appropriate approach for estimating the design flow in residential buildings. (‘Stemming the flow’, CIBSE Journal, April 2019). However, there has been little, if any, research to assess the validity of current design methods for non-residential buildings.

Non-residential buildings can be characterised as having significant water demand that is strongly influenced by occupancy profile. This means that water use during daytime hours is a specific feature that differentiates the profile from that for residential buildings. In the UK, however, the Loading Unit (LU) approach is currently used to estimate design flow rates for both residential and non-residential buildings.

Addressing oversizing and updating design methods has become more important because the problem not only introduces cost inefficiency, but can also have a negative effect on water quality.

Recently presented at the CIBSE ASHRAE Technical Symposium, this paper discusses the extent of the problem by presenting a comparison between design flow rates calculated from existing design guides and measured flow rates for four case-study buildings. It confirms that current methods result in an overestimation of design flow rate, and emphasises the need to develop a new design technique to support a better estimation of flow loading. It also presents an early-stage model that has been developed to estimate design flow rate specifically for non-residential buildings.

The loading unit method

The LU used to calculate the estimated design flow rates is based on work by Hunter, who developed the design curve in 1940. It forms the basis of the following UK design guides: BS 6700; BS EN 806; BS 8558; and CIPHE loading unit method. The CIPHE method is the only guide that can be recommended for non-domestic buildings, however, as it allows a specification of the time difference between the use of appliances. Low use is deemed to have a time difference of 20 minutes, medium 10 minutes, and high five minutes. High use would be for buildings such as theatres or sports venues.

The author measured the actual flow rate at four buildings using an ultrasonic flow meter at Heriot-Watt University. Three of them – the Estates Building, Postgraduate Centre, Hugh Nisbet– are non-domestic, and one, the Christina Miller Hall, is student accommodation.

For the Hugh Nisbet Building, the maximum flow rate was 1.6L.s-1, while, at the 99th percentile, the rate was 1.11L.s-1. (The 99th percentile figure is used in LU methods.)

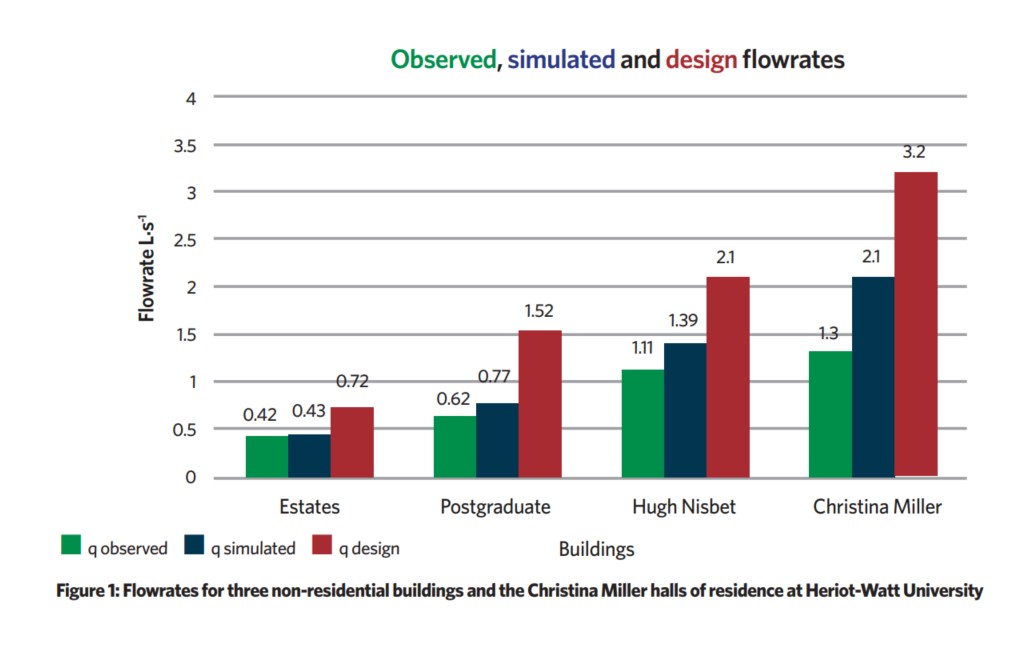

The actual flow rates were compared with the estimated design flow rate for each building using the LU method. The design flow rate was found to be significantly higher in each building, with the Hugh Nisbet’s estimated rate being 89% higher, at 2.1L.s-1. The largest overestimate was the Christina Miller halls of residence, which had a design flow rate 146% higher than the actual flow rate (see Figure 1).

New design approach

A new water-demand estimation model is based on the relationship between the number of users and the number of appliances, and when they are used. The Monte Carlo simulation method is used on this data to predict the probability of different outcomes. A Monte Carlo analysis is used when there are unknown variables and involves running many scenarios with different random inputs and summarising the distribution of the results.

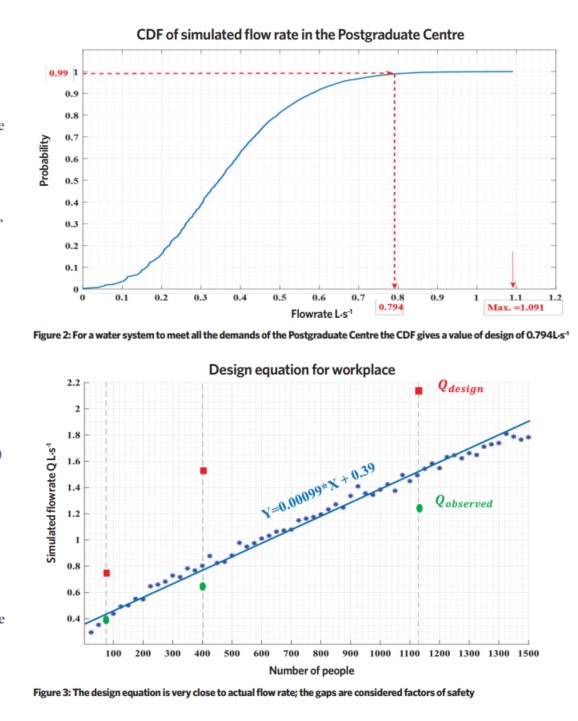

The model gives a probability distribution of flow rates and generates a cumulative distribution function (CDF), which gives a design flow rate for the system. Figure 2 shows the simulated flow rate for the Postgraduate Centre. To design a water system to meet all the building’s demand, you need 1.1L.s-1, but – for the 99% percentile – the CDF gives a value of design of 0.794L.s-1.

The simulated flow rate is very close to the actual flow in all four buildings, and there is a significant reduction in flow rates when compared with the design flow rate calculated using the LU method in current design guides (see Figure 2).

This model can be applied to calculate a simulated flow rate for a workplace with varying occupancy. In Figure 3, the X-axis represents the number of people, while the simulated flow rate is on the Y-axis. The points on the graph are obtained after running the model 200,000 times. By drawing a best-fit line, a design equation can be obtained, where Y=0.00099*X +0.39. To validate the model, actual flow rates have been measured in three buildings (plotted in green and red on Figure 3). The design equation is very close to actual (observed) flow rate. The gaps can be considered factors of safety. When compared to the rate obtained from the design guide, the actual flow rate is considerably lower.

Oversizing not only introduces cost inefficiency, but can have a negative effect on water quality A low-carbon retrofit strategy could use the shift to home working to create jobs across the UK

While further research is needed to cover other types of buildings with more occupants, this research suggests the model is much better than the current design guides at estimating flow rates. This offers the opportunity to avoid oversizing of water systems and, so, cut water use and reduce expenditure on plant.

■ Sarwar Mohammed is a PhD student at Heriot-Watt University

■ The paper New method to design flow rate in non-residential buildings was presented at the 2020 CIBSE ASHRAE Technical Symposium. All the papers and presentations are available at www.cibse.org/symposium, and are free to full-time student members and available for £50 for CIBSE and ASHRAE members.