Two Remeha 88kW ASHPs supply all the heat to Witham Academy’s swimming pool building

According to the latest government research, schools and universities across the UK account for 36% of public sector building emissions1. Taking action to reduce the carbon footprint and lead by example is understandably high on the school agenda – and with funding from the government’s Public Sector Decarbonisation Scheme (PSDS) making the energy transition more affordable and achievable, astute school trusts are seizing the opportunity to start their net zero journey.

The Priory Federation of Academies Trust, for example, has recently carried out a programme to decarbonise the swimming pool centres at its secondary academies in Lincoln. Renewable energy installer Oakes Energy Services collaborated with heating and hot-water solutions provider Baxi to assist the Trust with its ambitious sustainability initiative, replacing existing standard gas boilers with air source heat pumps (ASHPs).

Proposals for the decarbonisation programme began in 2022, with the Trust identifying an opportunity to reduce the high energy demand in three swimming pool buildings. Typically, swimming pools are extremely energy-intensive because the water needs to be heated continuously to maintain comfortable temperatures.

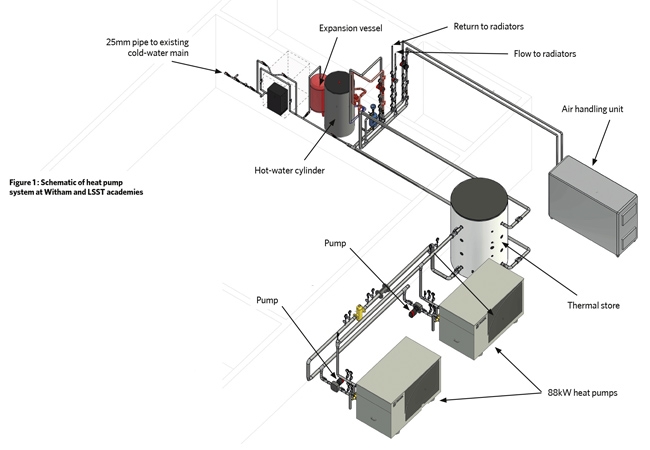

Gas boilers were heating the water in the pools at Lincoln Academy, Witham Academy and LSST Academy – but, today, two 88kW ASHPs supply all the heat demand in the swimming pool buildings at Witham and LSST, feeding underfloor heating and radiators, and providing hot water for the changing rooms and the swimming pool plant.

At Lincoln Academy, which has a larger 25-metre pool, five 88kW ASHPs are supplying heat to 500-litre calorifiers for the hot-water system, as well as to the swimming pool heat exchanger, in the first phase of the decarbonisation programme.

Oakes Energy Services, which specialises in decarbonising existing buildings, was approached by the Trust to develop initial proposals to secure PSDS funding for the programme. Director Nik Smith FCIBSE describes the process: ‘We start each project with an initial assessment of the building’s energy profile. We then review decarbonisation options and the anticipated carbon savings – which were considerable across the three schools – and present these in a design proposal.’

The proposal for each academy was designed to meet the individual requirements of each building, but all involved retrofitting ASHPs and calorifiers supplied by Baxi. In total, the design of the entire scheme is projected to save 227.5 tonnes of CO2 a year.

Figure 1 : Schematic of heat pump system at Witham and LSST academies

Detailed design

PSDS funding was successfully secured through Salix in 2023. With the competitive tender process won, the starting point when developing the detailed design was to produce comprehensive building heat-loss calculations.

Understanding the thermal performance of a building is important to develop solutions to improve its operational efficiency. The problem with existing buildings, however, is the lack of thermal modelling and legacy issues, says Smith. ‘You can inherit all sorts of problems, including what has happened between when the existing plant was fitted and now.’

To address this, a commissioning engineer assesses the site before any work is carried out and takes flow readings. Any assumptions made can then be validated for improved accuracy through what the company terms its ‘prevalidation’ process.

At all three buildings, a full assessment of the electrical infrastructure was carried out to ensure efficient capacity to site. The team evaluated the suitability of the heat emitters and pipework, and determined any upgrade requirements.

The location of ASHPs at schools requires careful planning to protect against vandalism, with the footprint, maintenance clearances, noise levels, hydraulics and electrical connections, general aesthetics, and any necessary planning permissions all factored in.

Lincoln Academy’s larger 25m pool requires five ASHPs

The final design proposals included new pipework, inverter-driven variable speed high-efficiency pumps, thermal stores, air handling unit upgrade, power and BMS controls, upgraded internal heat emitters, water treatment, and balancing.

The BMS controls philosophy is programmed to use the reduced overnight electrical tariff to pre-charge the thermal stores so the system is at full capacity, ready for operational hours. The temperature setpoints are designed to deliver changing rooms, offices and corridors at 21°C.

Within the pool hall, the water temperature setpoint of 30°C and air temperature setpoint of 31°C allow the most suitable environment for students. To maintain hot-water temperatures outside of the legionella band, the domestic hot-water temperature needs to remain above 50°C, and up to 60°C for an hour daily, with pasteurisation carried out weekly.

Using a cascade of heat pumps can improve the overall performance of the system by offering adequate turndown to meet the system load requirement throughout the year, preventing excessive cycling of the heat pumps, as well as improving overall efficiency by operating a number of heat pumps at part load. The new units were commissioned in September 2023, ahead of the start of the new academic year.

Benefits of early collaboration

Retrofitting ASHPs brings opportunities and challenges in schools because of the need to minimise disruption and keep the buildings operational during term time. This typically leads to works being carried out during the summer holiday shutdown period.

Smith outlines two factors that helped keep the programme on schedule to provide heating ready for the school’s return in early September. One was collaborating with the supplier to ensure availability. ‘Knowing heat pumps were in stock was a big selling point, as we could get ahead with preparatory works before the holidays while keeping the building and academy operational.’

This included preparing the heat pump locations’ bases and external pipework before removing the existing boiler system to make space for the new systems’ proprietary equipment. ‘Collaborating with the manufacturer from the outset also meant we benefited from great support throughout, from onsite technical support during the installation stage to pre-commissioning support and final ASHP commissioning by its engineers to meet the handover date,’ Smith continues.

The second tip Smith offers is to notify the local Distribution Network Operator (DNO) and complete the necessary connection application form as soon as the heat pump design is locked in. ‘Applying immediately can avoid potential delays waiting for DNO approval, so it’s advisable to do this at the outset,’ he explains.

The location of ASHPs requires careful planning to protect against vandalism

Energy monitoring and revisiting

There can be challenges when retrofitting ASHPs in an existing building because of the need to achieve hydronic balancing. Reviewing the system regularly and monitoring energy usage – a Salix requirement – will enable anomalies to be identified and rectified immediately, to keep operational efficiencies high.

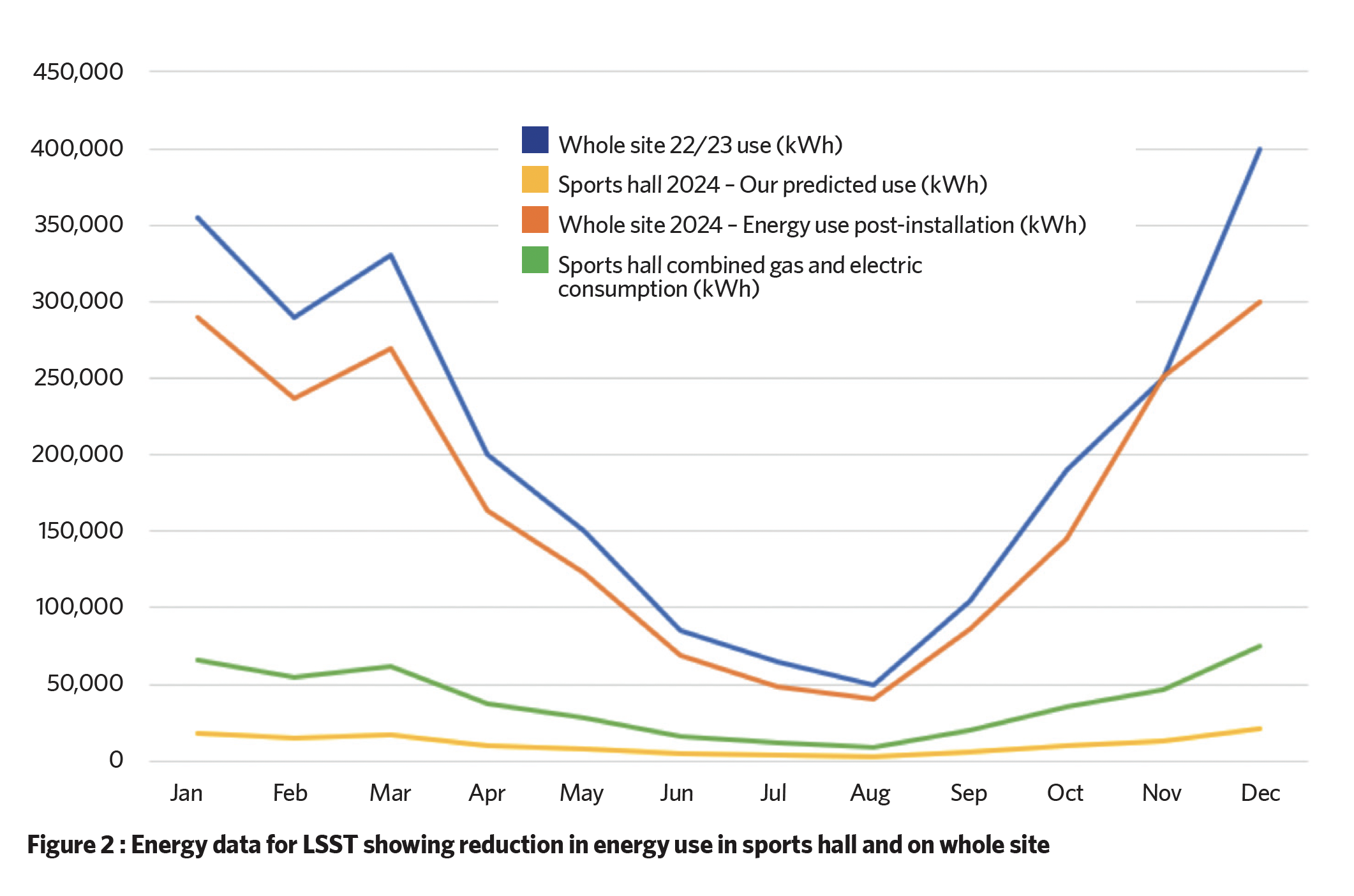

One of the challenges was calculating previous energy usage in the buildings, according to Smith. ‘The swimming pool centres are separate from the main school buildings, but none of them was being metered independently,’ he says. ‘This meant that, while actual data can now be included, a lot of data prior to installing the ASHPs had to be predicted.’

A temperature comparison has been carried out from 2022, when the gas boilers were providing the energy, and 2023, when the ASHPs were providing the energy. This shows that average external October temperatures were 5-6K colder in 2023 than 2022 and, in November and December, around 2-3K colder in 2023. Both LSST and Witham are tracking exceptionally well against predicted performance. (Energy data for LSST is shown in Figure 2).

However, original data for Lincoln Academy indicated issues that, on investigation, were the result of thermal balancing. These have been corrected.

‘The importance of monitoring reliable energy data and going back to make sure the system is operating as anticipated can’t be overstated,’ says Smith. ‘Retrofitting ASHPs is complicated. This project involved a number of commissioning engineers for hydronic balancing, water treatment, and the BMS, as well as the ASHP manufacturer. But as we saw at Lincoln Academy, it’s essential to commission as a whole system to achieve the right thermal balance.’

He suggests that recommissioning in winter is critical to optimise operational efficiency during the months when the system has to work hardest. ‘On most school refurbishments, commissioning takes place during the summer,’ he says. ‘But how are they performing in winter? It points to a need for recommissioning in the winter months to keep operational efficiencies high.’

In addition to spending time educating estates managers and BMS operators on the ASHP system, the project highlighted the benefit of ongoing review to optimise ASHP performance. ‘Issues might come to light – for example, the timing of the pasteurisation cycle during an occupied period, or the pool cover not being fitted – that can be addressed quickly, to bring the energy back under control,’ says Smith.

Importance of funding to drive energy transition

The Priory Federation of Academies Trust is delighted with the outcome in its three swimming pool centres, and its decarbonisation programme has caught the eye of Salix Finance, which has nominated the Trust for one of its sustainability awards.

PSDS funding is vital to drive the energy transition in the education sector, says Smith. ‘ASHPs on school retrofit projects will deliver vital carbon savings, but are currently not financially viable without government funding, especially where special deals have been negotiated on gas prices.’

‘Fortunately, we have recently received confirmation from the Department for Energy Security and Net Zero that Phase 4 of the PSDS, amounting to £1.17bn, is now available,’ he adds.

When embarking on an ASHP retrofit project, a good understanding of the building and its energy usage is essential to produce design options for improvement, as well as to predict operational and carbon savings. Monitoring the system and tracking actual energy data against predicted outcomes then provides the opportunity to revisit, and ensure the control strategy and balancing is optimal after a time of operation.

About the author

Andy Green is technical director at Baxi

References:

- Sustainability and climate change: a strategy for the education and children’s services systems, Department for Education, 2023 bit.ly/CJCCEd