Nobody said decarbonising heat was going to be easy.

Current discussion is whether it should be done with decarbonised electricity, preferably with a heat pump, or with decarbonised hydrogen that will replace the natural gas [methane, CH4] in the UK’s extensive gas grid.

The government’s recent backing of hydrogen for transport, energy storage and decarbonised industrial feedstock has kept this debate alive, but not answered it.

The thinking engineer’s money is firmly behind the electrification of heat in buildings for very good reasons, not least that the whole system of renewable generation, electrical distribution and heat pumps is available to use today.

By contrast, making zero carbon hydrogen from methane and sequestering the CO2 [blue hydrogen] – or, better, from renewable electricity and water [green hydrogen] – is still a cottage industry. The safety and viability of converting the gas distribution system in the grid and in buildings from CH4 to H2 is still work in progress.

I understand that developing a gas appliance to transition from methane to hydrogen is not that hard and many manufacturers have done the R&D on it. However, most people, including proponents of hydrogen for other uses such as transport, think simply burning it is a criminal waste of a precious resource.

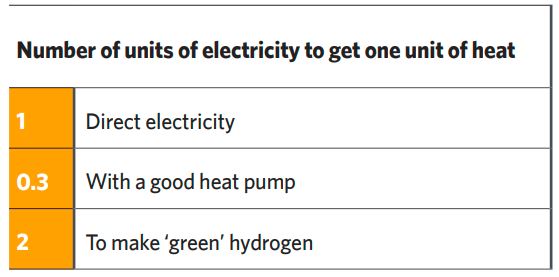

Compared to a heat pump that may give you three times more heat than the electricity you put in, a hydrogen boiler might only give 0.5 units of heat per unit of electricity to make green hydrogen – a factor of six worse. Given this, installing gas heating and waiting for hydrogen in the grid is not a serious route to decarbonisation.

For the whole country to decarbonise, every home will have to move away from gas heating, not just clients who are concerned about climate change and are the thinking engineers’ customers. A realistic timescale for this is 25 years, so we should not be thinking only about what is available now, but also what the future of energy generation and supply will look like.

The thinking engineer’s money is firmly behind the electrification of heat in buildings for very good reasons

Providing enough zero carbon power to meet our current needs is no trivial matter. More green power is required. I believe that the UK thinks offshore wind will provide its power needs by extending further into deeper water. Perhaps this could be done – but it will be hard because of its intermittency.

I would like to know if climate change is also likely to exacerbate the intermittency of wind energy in the same way as rain and water supply. One hears about the storms, but prolonged bouts of hot stable air could reduce the availability of wind energy. The solutions to intermittency of any resource is generally a choice of:

- Collect far more wind and solar energy than needed and waste the excess.

- Store excess production to use at times of low production. This is the obvious solution. Short-term electrical storage in batteries or physical systems such as pumped hydro/falling weights/compressed air schemes are viable for short term fluctuations over a day or two, but not months. For this, you need to have a store of chemical energy such as hydrogen.

- Collect from a wider area on the basis that somewhere is always in surplus to serve areas in deficit. This involves trading the resource with other areas that are in different weather systems or always have a surplus.

Finding the right mix is what the next 10 years will be about. Solar and wind fuel is free, and the costs are made up of the infrastructure to capture, store and distribute the energy.

Wind installations will generate power at 4p/kWh, but only if most of the power is sold and not wasted. An energy storage system will only earn its keep when it cycles power in and out.

Daily storage would produce 365 cycles, whereas monthly would only produce 12 cycles a year to pay for the installation.

None of the solutions are currently easy or cheap, which is where hydrogen comes in. The cost of renewably sourced hydrogen is in the power, water, the hydrolyser to split the water, and the cost of storage transport.

One of the past decade’s success stories for renewables is the rapid fall in the cost of solar power as the market has expanded. In the sunniest countries, the cost of electricity is falling to 1 cent/kWh from commercial plants. There is a challenge to get renewable hydrogen down to $2/kg [which is 5 cents/kWh] in four years. With the current commercial focus from wealthy oil exporting countries to solar, this is possible. Costs are unlikely to stop falling as demand becomes global.

Having solar-produced hydrogen delivered to the UK at 3p/kWh or less is possible within 10 years. This would give us the flexible supply that natural gas does currently. We could make our own Great British hydrogen in a turbine in the Atlantic, but I suspect it would cost more than solar energy from the desert.

The alternative way to get power from other climate zones is with a power interconnector. China has completed 3,000km high-voltage direct current power lines to transport 12GW of power from the windy central plains to eastern population centres. They are keen to promote a global grid to move power around the globe.

In the UK, it is an uphill struggle to achieve the changes required to decarbonise heating systems, so the less hassle required, the better. As such, a simple change from natural gas to hydrogen (keeping the same boiler) has its attractions. All the engineering and health and safety issues surrounding this are still there, but the government research timetable will give a decision on hydrogen in heat by 2026.

In those three years, a third of the UK’s boilers could have been replaced and will last a further 15-20 years. If we do pivot to hydrogen, they should be capable of being switched from natural gas.