The post-pandemic period has given designers the opportunity to review and renew their approach to ventilation in commercial buildings, based on demand for healthier buildings that cater for more flexible working patterns.

There has been a multitude of guidance documents produced in recent years reflecting this new normal, with HVAC institutions around the world issuing advice to help reduce Covid-19 transmission risk.

Many of these recommendations are aimed solely at reducing virus transmission, however, without considering the overall effect on building operation and sustainability.

This study investigates ventilation and indoor air quality (IAQ) in a commercial office, using Covid-19-related best practice guidance to improve performance and sustainability. Much of the research was made possible by the CIBSE Ken Dale Bursary, which was awarded in 2020-22.

The study focused on the ventilation and IAQ in Arup’s office in Cork, Ireland. Designed to Leed Gold standards, the office was the first in Ireland to achieve the WELL Gold standard for fit-out. Located on the first floor of the One Albert Quay building, the office provides 1,900m2 of commercial office space, with an occupancy of 180 people.

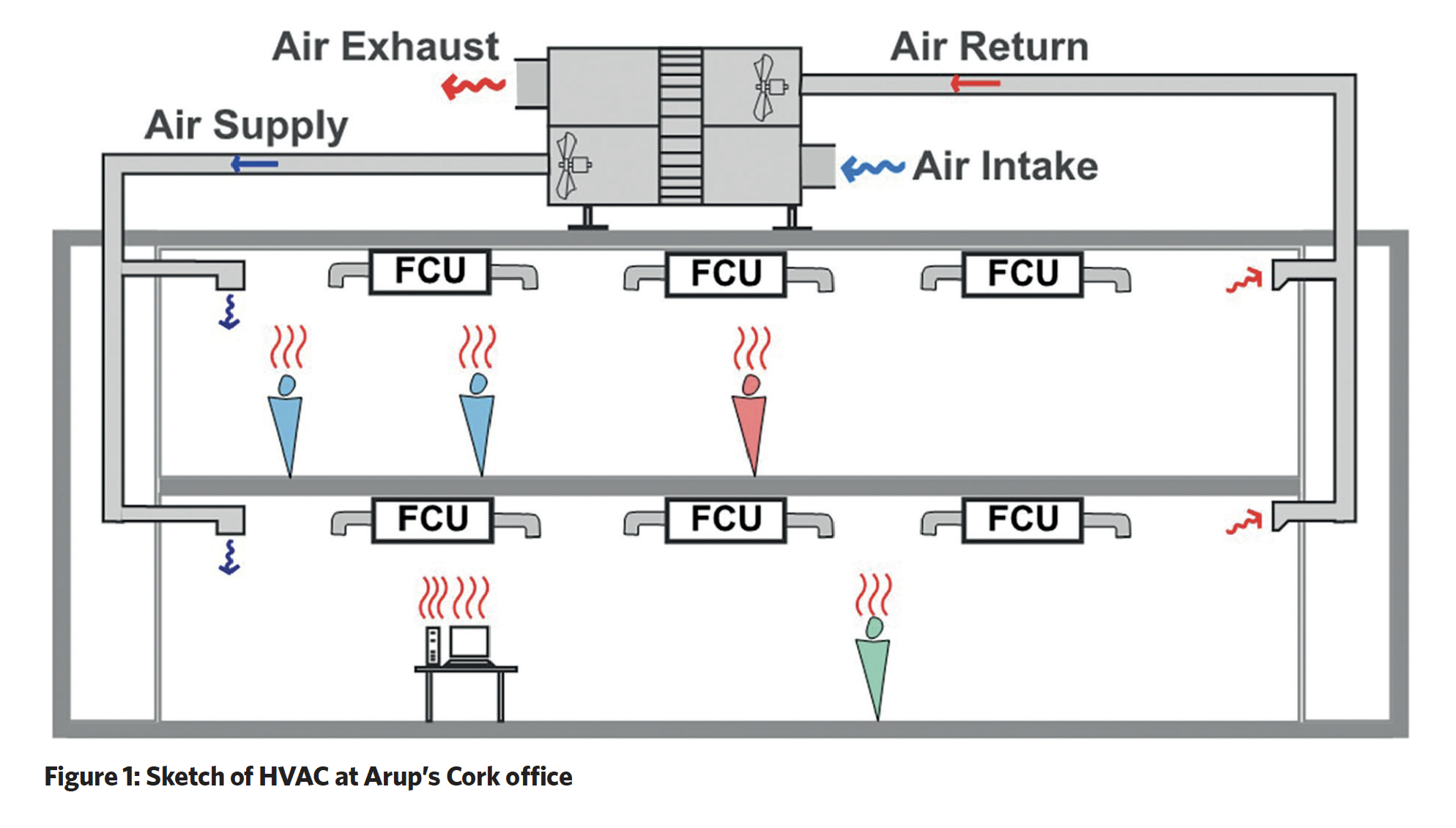

The HVAC system of the office uses minimum efficiency reporting values (MERV) – 13-filtered constant volume supply air from a dedicated outdoor air supply air handling unit (AHU) with thermal wheel. This has been ducted to the office ceiling plenum towards the back of specified zone variable refrigerant flow fan coil units (FCUs). (See Figure 1.)

The FCUs supply tempered air to the room via ducted high-level ceiling swirl and disc diffusers, with return air extracted from high level via ducted swirl grilles. Eggcrate plenum return grilles in the ceiling enable recirculation of some return air to the supply air through the plenum FCUs.

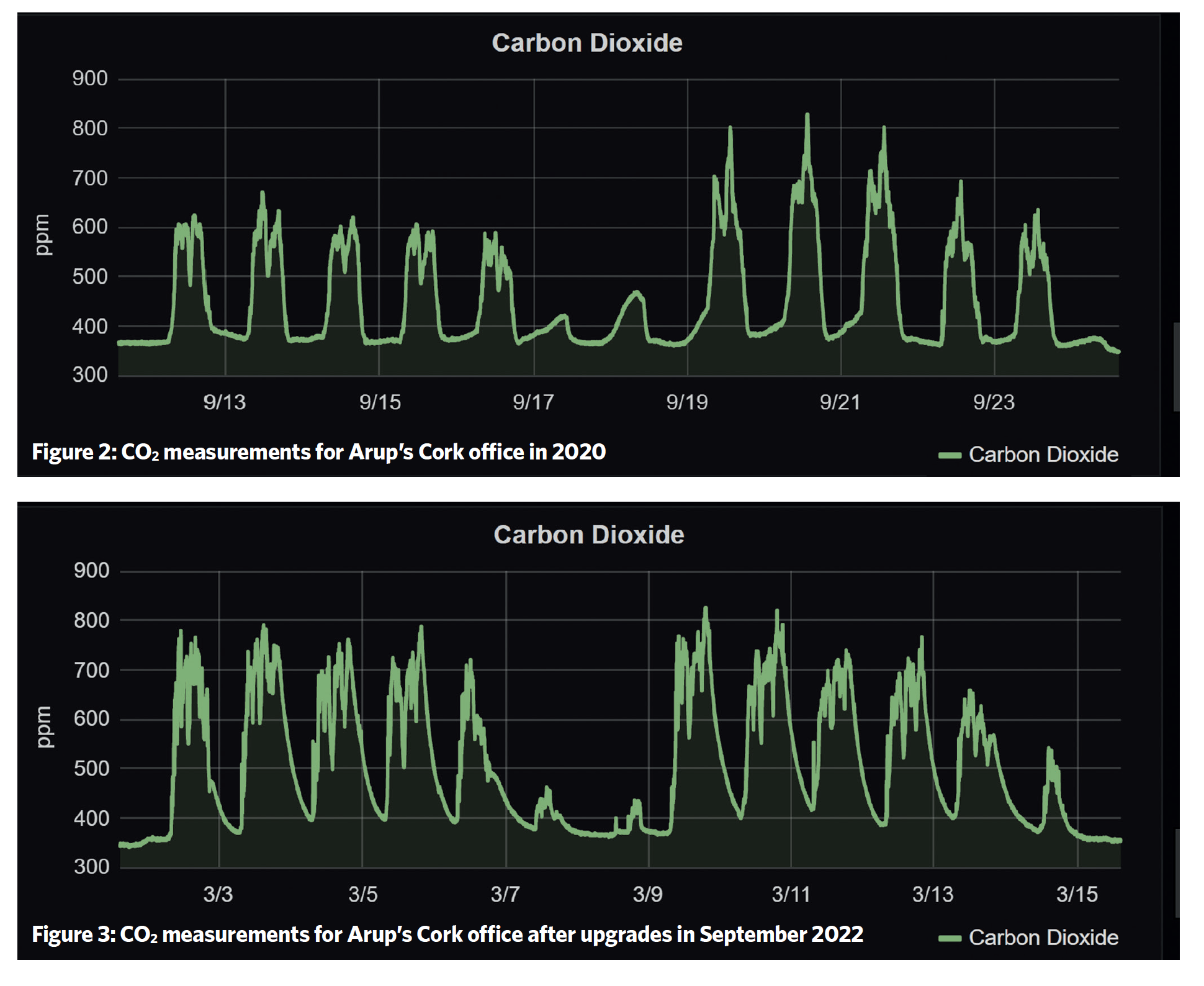

To assess the effectiveness of the ventilation system, operational CO2 data was compared with design data using an Arup BPS Arc IAQ monitor with NanoSense E4000 auto-calibrated CO2 sensors. The sensors have an accuracy of +/- 50 parts per million (ppm) at standard test conditions.

Taking the last two, fully operational ‘normal’ weeks pre-pandemic of 2 March to 15 March as the analysis period, the investigation found that, during occupied hours at the office, the average value measured for CO2 was ~750ppm (Figure 2). Peak occupancy levels exceeded 800ppm, which is >150ppm greater than the expected level based on design for WELL certification, ventilation rates and ventilation effectiveness (Ev) calculations.

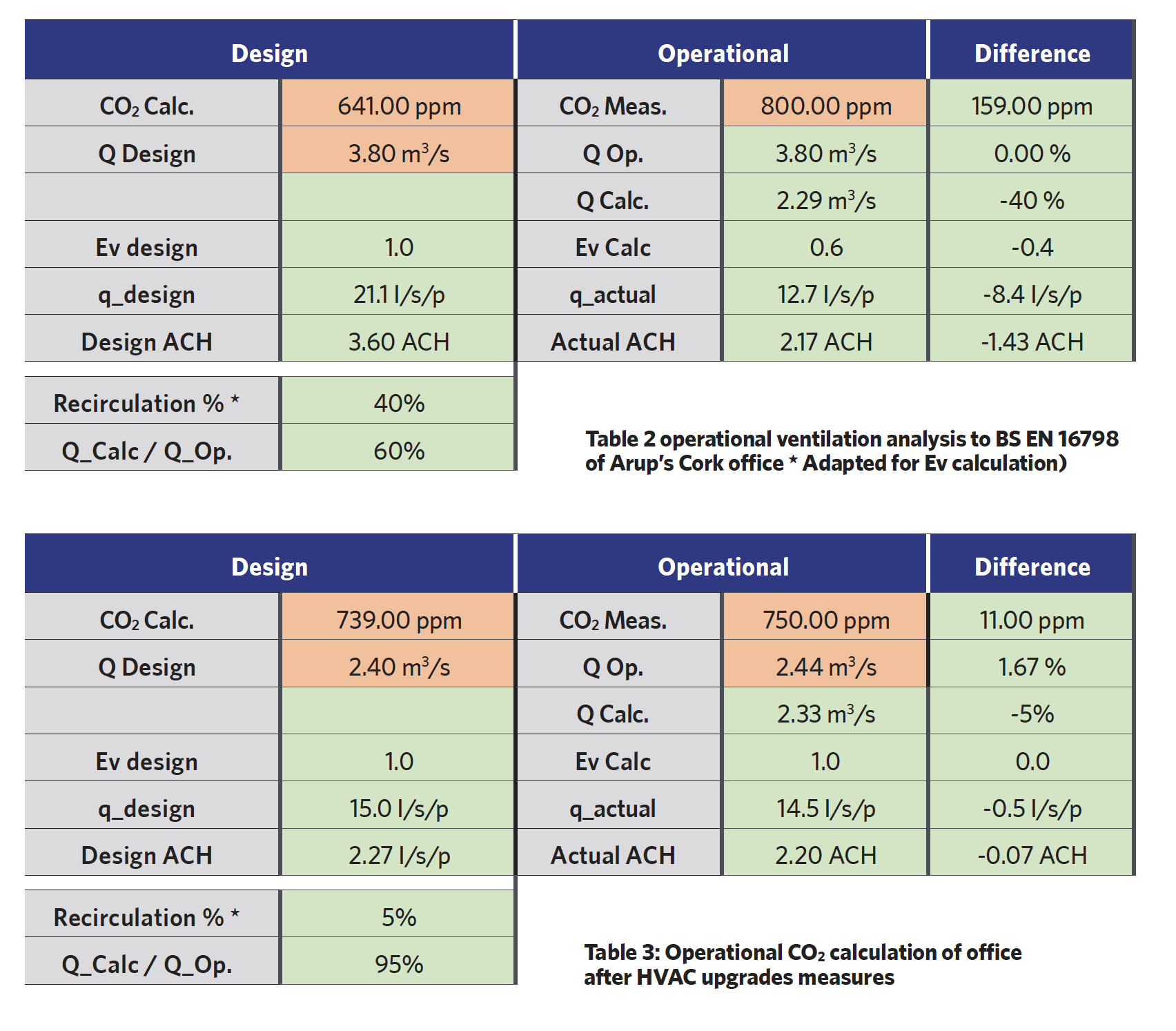

Arup Cork office should be a premium office space, aiming to achieve BS EN 16798 IAQ II category or better in design (assuming low polluting at a minimum). The office fit-out design ventilation rate is approximately 21 L·s-1 per person and 2 L s-1·m-2, which translates to an IAQ Category 1 environment (see Table 1). Using the adapted Method 2 (BS EN 16798-1) limit values for substance concentration formula, this can be translated to expected zone CO2 levels, and may be compared against the table of classified absolute indoor CO2 levels to categorise the design IAQ level.

Based on this, an estimated design CO2 concentration of ~650ppm is expected, which is an IAQ Category I classification.

Resulting zone CO2 values will not be exact because of variances in occupant activity and outdoor CO2 levels. However, operational measure values can be compared against a range (i.e. 650 ± 50ppm) to help identify if there are any significant variances between design and operation expectations.

Operational stage measured CO2 data is about 750-800ppm. This is ~100-150 ppm greater than the calculated design CO2 value of 650ppm, which is well outside the allowable range (650-700ppm) and may indicate an issue with the operation of the ventilation system. Taking this measured CO2 value as the indoor concentration, and using the BS EN 16798 Method 2 formula to calculate the corresponding ventilation rate, the IAQ-calculated supply airflow is only 2.3 m3·s– 1 in the zone, a difference of 40%.

By using both the measured operational ventilation rate and indoor CO2 value, the ventilation effectiveness is estimated to be 0.6. This result was much lower than the 1 assumed for the high-level mixing ventilation system applied in the office (see Table 2). This indicated that there was either a significant leakage of supply air and recirculation of exhaust air in the ventilation system, or the effectiveness of the ventilation system was compromised, with airflow short circuiting occurring.

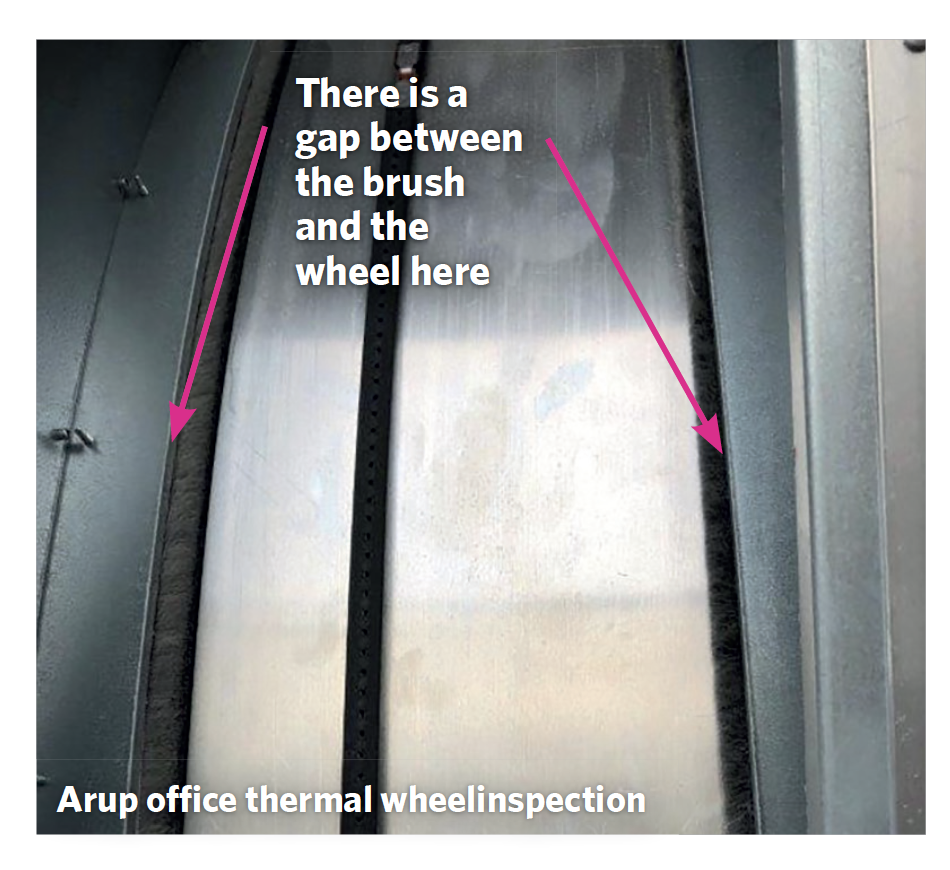

Further onsite investigation revealed a significant gap in the AHU thermal wheel brush seal (see image, below left), which allowed exhaust air to leak into the supply air, assisted by a negative fan-pressure regime. This short-circuited the AHU, reintroducing exhaust air into supply air and compromising the effectiveness of the ventilation system.

Steps to improve air quality

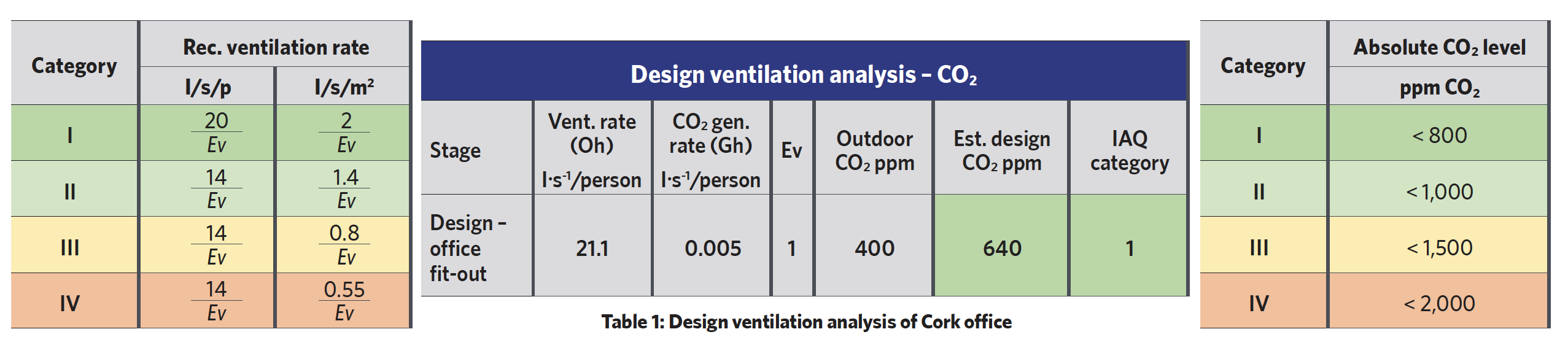

By March 2022, post-Covid-19 HVAC measures were implemented to provide a high-occupancy supply airflow of 2.44 m3·s– 1 with a new office capacity of 160, creating an outside air ventilation rate of ~15 L·s-1 per person, as per design. This resulted in an IAQ Category II environment (based on 15 L·s-1 per person) or, at an estimated CO2 value of ~740ppm (± 50ppm), a Category I environment (see Table 3 and Figure 3).

The main, high-impact measure was the mechanical ventilation with heat recovery upgrade. Upon inspection, significant thermal wheel sealing deficiencies in the AHU were identified. This, with the negative pressure differential produced by the fans’ operation, was reintroducing exhaust air into supply air, providing explanation for the higher-than-expected CO2 levels within the office identified in the ventilation analysis.

The recommendation to upgrade AHU thermal wheel sealing, and to update the fan-speed operation and differential pressure control, was carried out in stages over the summer of 2020. A thermal wheel purge sector, although originally recommended in 2020, was not easily retrofitted into the unit, so was not installed. After further research, it was no longer deemed necessary because of additional exhaust filtration, and the fact that it would induce greater leakage in the AHU. Additional measures to install updated IAQ monitoring and FCU filters in the offices are ongoing.

This study highlights the importance of considering the overall effect on building operation and sustainability when implementing HVAC guidance to reduce transmission risks. It is not enough to focus on virus transmission without considering the potential impact on the effectiveness of the ventilation system and energy consumption.

- This paper was presented at the CIBSE ASHRAE Technical Symposium last month