The Modutherm electrode featured before and after insulation

The energy crisis of 2021-22 exposed significant flaws in the UK’s heat network infrastructure. While domestic electricity and gas tariffs were capped, heat networks – unregulated at the time – remained fully exposed to wholesale market volatility. In one Edinburgh scheme, tariffs soared by 450%, from 4p to more than 22p per kWh.

This volatility has impacted low-income households disproportionately. Social housing providers – many of whose residents are on fixed incomes or Universal Credit – are under pressure to find heating solutions that reduce carbon and cost while addressing the persistent challenge of fuel poverty.

With new heat network regulations coming into force in January 2026, the sector must deliver systems that are not only compliant, but also equitable, affordable and future-ready.

Engineering consultancy Jacobs has developed a novel approach to network design that maintains comfort, reduces emissions and avoids pushing vulnerable users into fuel poverty. The result is a Generation 4.5 heat network.

This next-generation network operates with 45°C flow temperatures (W45) for most of the year – warmer than ambient 5th-generation networks, but cooler than the 55-65°C typical of 4th-generation systems. This ‘smart middle ground’ optimises carbon reduction, energy efficiency and affordability.

Dual-mode design

Lower network temperatures improve system efficiency and reduce heat losses – both of which help to mitigate fuel poverty. Traditional 4th-generation networks often maintain higher temperatures to ensure at least 50°C domestic hot water (DHW) at the tap.

While high-temperature heat pumps, such as CO₂-based systems, can meet these demands, they often operate with a lower coefficient of performance (COP), increasing running costs. Maintaining high flow temperatures year-round also increases the unit cost of delivered heat. A more dynamic, weather-responsive approach is needed.

Generation 4.5 heat networks operate at W45 most of the year, increasing to W60 only during colder periods. This dual-mode design supports hybrid systems that incorporate both passive and active heat sources, maximising efficiency in mild weather while ensuring comfort and resilience during colder months.

In one case study, reducing flow temperature to 45°C for 80% of the year improved the seasonal coefficient of performance (SCOP) from 2.4 to 3.9, making the system more cost-effective than gas on a per-kWh basis.

Ensuring DHW remains safe at lower flow temperatures is critical, as water must typically reach at least 50°C at the tap to mitigate legionella risk. To address this, the design team collaborated with manufacturer Modutherm to introduce a boost electrode on the primary side of the heat interface unit (HIU).

This small electric heater activates only during DHW demand when network flow is below 55°C, lifting water temperature to a safe outlet level – ensuring comfort and hygiene without compromising efficiency.

Realising the potential of Generation 4.5 required extensive prototyping. Working with Modutherm, the engineers tested a W45-compatible HIU incorporating an integrated immersion heater.

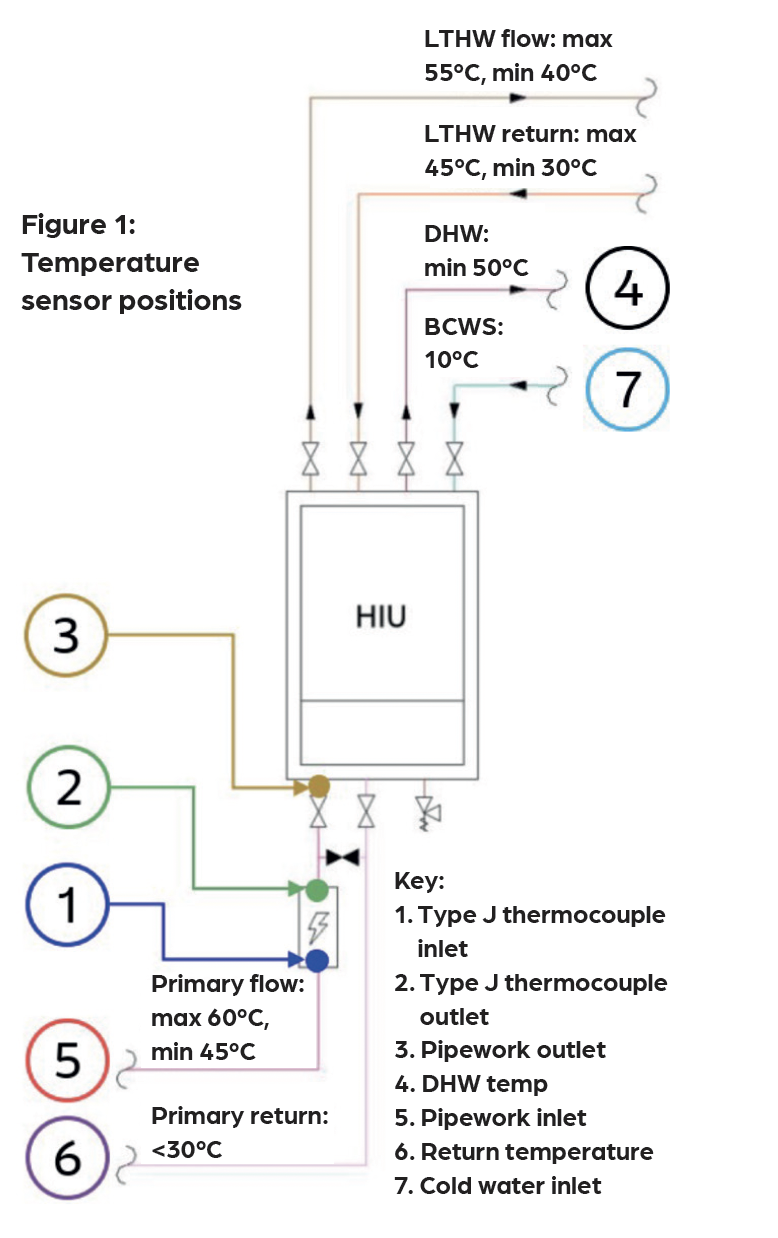

Seven temperature sensors monitored system behaviour (Figure 1), with the electrode activating only when flow temperatures dropped below 55°C and there was DHW demand. It deactivates if inlet temperatures exceed 60°C, creating a controlled cycling pattern. Safety is managed via an 85°C thermostat and a 130°C thermofuse.

Control is embedded within the HIU to reduce dependence on the thermostat and prolong component lifespan. Test results showed stable DHW delivery, with the electrode fully energised during high-flow events and pulsing during low-flow draws. These trials demonstrated that it is now technically feasible to reduce flow temperatures while maintaining comfort and safety.

Bridging the ‘spark gap’

To maximise the efficiency of the lower-temperature network in the case study, engineers specified propane (R290) heat pumps. Compared with synthetic refrigerants, such as R32, R290 offers a higher SCOP at low flow temperatures and supports greater system efficiency.

That performance gain is critical to bridging the ‘spark gap’ between electricity and gas. R290 also has zero ozone depletion potential and a low global warming potential. Safety is ensured through leak detection and automatic shutdown systems.

To avoid oversizing the boost electrode and minimise electrical infrastructure upgrades, flow restrictors were installed on outlets to control DHW draw rates. Instead of designing for all taps running simultaneously, the system was sized around the most demanding single use case: the shower. This approach kept the electrode rating below 7kW, avoiding expensive rewiring. Test data confirmed stable DHW delivery and reduced electrode wear because of intermittent cycling.

Balanced option

Lower-temperature networks also require radiator resizing to maintain thermal comfort. The team resized emitters where needed, especially in corridors adjacent to bathrooms, where thermal loads were higher. They also analysed building heat loss, which decreases significantly in milder conditions.

In many UK cities, more than 90% of the year is spent above freezing, making W45 a more appropriate baseline than worst-case winter assumptions. This ensures infrastructure sizing reflects real operating conditions, and reduces both capital and operational costs.

When compared with traditional storage heaters, fossil-fuel systems and even some 5th-generation designs, Generation 4.5 emerged as the most balanced option. It delivers a mix of low carbon, low cost and low risk.

The system is also highly adaptable – suited to new builds with underfloor heating and to retrofits where conventional radiators remain. It integrates effectively with waste heat sources and supports smart, demand-led control strategies.

Heat networks are monopolies by nature; residents cannot choose an alternative supplier. That makes it essential to get the design right – not just for compliance, but for fairness, comfort and long-term viability.

Generation 4.5 proves that heat decarbonisation can be delivered affordably, efficiently and equitably. With intelligent controls, propane heat pumps, DHW boosting and responsive network design, this approach offers a replicable blueprint for clean, low-cost, low-risk heat.

As Ofgem regulations and assurance frameworks come into force, Generation 4.5 provides a ready-made path to compliance – and a practical step forward in delivering the UK’s net zero ambitions.

About the author:

Adam Selvey FCIBSE is director of engineering design and innovation at Jacobs

The article is based on the paper45°C water for generation 4.5 heat networks, which was accepted for the 2025 CIBSE IBPSA-England Technical Symposium 2025. Authors are Thomas Howes MCIBSE, ; Adam Selvey FCIBSE, and Ryan Beale, building services engineer at Jacobs