The sweeping roof shading the outside eating area is made of custom glass panels with amorphous silicon solar PVs

The original concept for the Walt Disney World campus in Florida included a new community that would serve as a centre for American enterprise and urban living. Walt Disney’s death meant the vision of a new city was never realised, but the concept was reprised in the Epcot theme park, which opened in 1982 and showcases modern innovation. It’s been wildly popular since it opened and is the fourth most visited theme park in North America.

It is fitting, therefore, that McDonald’s designed and built the world’s first net zero energy fast-food restaurant on the Walt Disney World campus. The all-electric building has achieved more than 105% net positive energy for 12 consecutive months, thanks to a roof-mounted solar photovoltaic array.

Quick-serve restaurants have very high energy use intensity and, with a 24-hour operation, some creative engineering was required to minimise loads.

Cooking appliances consume 55% of the building’s annual energy, while building ventilation is the second-largest load. The majority of ventilation is replacement air for the cooking hood exhaust system, which runs 24 hours per day.

To minimise kitchen exhaust, the kitchen hood exhaust system uses cooking demand-based ventilation controls. These monitor heat, grease and smoke, and adjust exhaust rates to maintain effective capture and containment.

Quick-serve restaurants have large fluctuations in service and have to provide meals to customers on demand. A typical restaurant will keep their cooking lines hot 24 hours a day, so they can react instantly to an influx of customers. This is not only a major energy consumer, but it also adds significant cooling load and keeps the kitchen hood demand-control system from going to minimum flow.

A new technology in quick-serve cooking allows an entire line to go idle and rapidly switch to ‘ready’ when required

At the Walt Disney World restaurant, McDonald’s deployed a new technology in quick-serve cooking that allows an entire line to go into idle mode and rapidly switch to ‘ready’ when required. This location handles an extraordinarily large number of customers given its proximity to the theme park and has a very large kitchen to handle the demand. There are three cooking lines and being able to bring them to an idle state during lower demand times significantly reduces ventilation and energy load.

Kitchen pressure is held at a 5% negative to adjoining spaces to keep kitchen odours contained. Having a variable exhaust system means the kitchen make-up air unit, and the dedicated outdoor air unit for the adjoining dining room space, must react in sync to maintain a proper pressure balance. Both the make-up air unit and dedicated outdoor air unit have variable speed drives and space-pressure sensors for control. Commissioning this system was complex and required simulation of many scenarios of cooking and occupant loads to tune properly.

The most unique ventilation strategy was the incorporation into the dining room of a natural ventilation system. While this complicates the pressure control of the kitchen, it provides significant energy savings and enhanced occupant comfort.

Orlando is a subtropical climate, classified under the Köppen climatic classification as Cfa. The area has two seasons: hot and rainy, and warm and dry. May to September is considered the hot and rainy season, with high temperatures typically around 32oC and average lows between 18oC and 23oC, with frequent heavy rain. The warm and dry season spans from October through April, with average high temperatures between 20.5oC and 28.8oC and lows between 8.8oC and 18oC. The warm and dry season experiences about half as much rain as the hot and rainy one.

The operative temperature range for the dining area is between 20oC and 25.5oC. Because the restaurant operates 24 hours per day, natural ventilation is available most often at night, when the seasonal temperature ranges are within the operative temperature range. With the wide operative temperature range, the store has 3,800 hours of natural ventilation per year (43%).

The natural ventilation system was commissioned not only to monitor dry bulb temperature, but also enthalpy, wind speed and precipitation. When the weather conditions are within all ranges, operable glass louvres that line the entire south and west façades of the dining area open, while the variable refrigerant flow system providing space conditioning, and the dedicated outdoor air unit providing ventilation, shut down. Natural ventilation fans draw air through the space and help maintain the pressure balance to the kitchen.

Having the natural ventilation glass louvres at the customer level posed a safety concern that had to be accounted for carefully. Louvres could have an item placed in them, or a customer may put their hands in and get them caught.

To address safety concerns, the inside is screened; this also keeps pests or debris from entering the restaurant. On the exterior, a laser system creates a field covering the entire surface of the louvres, and instantly disables actuation of the system if an object is detected. Actuation starts again when the object is removed. An audible message also alerts customers when the louvres open or close, and an internal safety mechanism detects added pressure and prevents complete closure. The commissioning authority tested this and still has all his fingers!

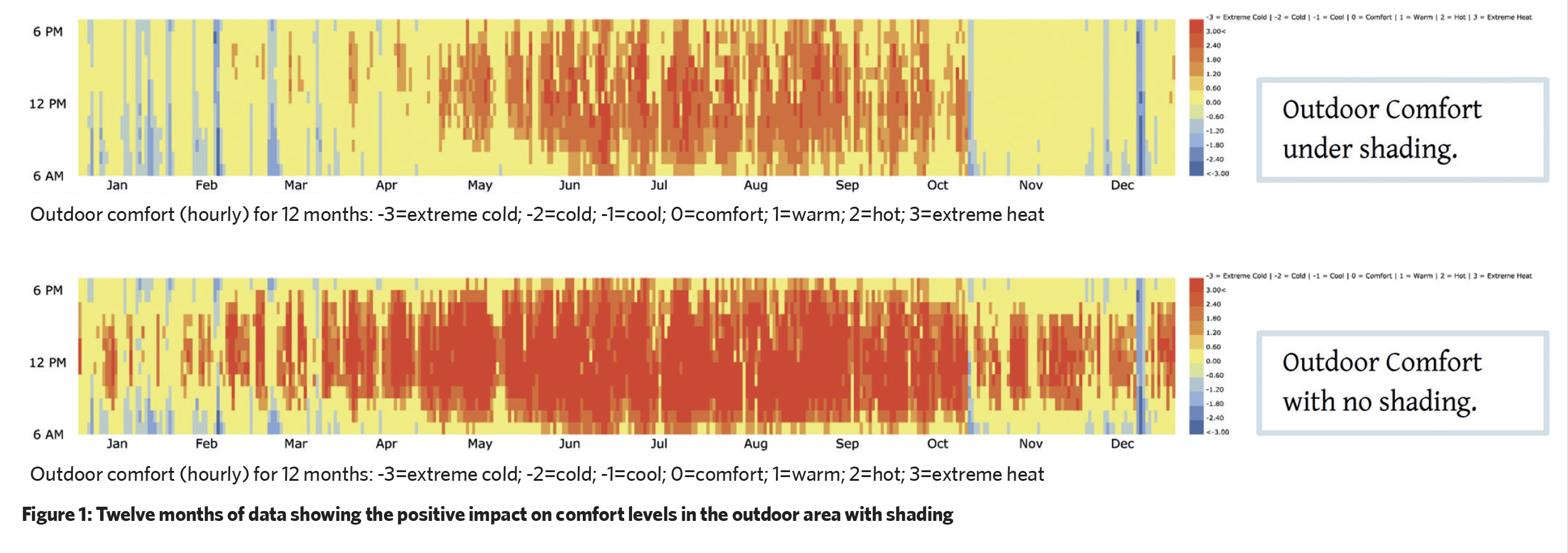

Comfort is maintained in the outdoor area 58% of the time annually between 6am and 6pm

Outdoor dining is not typical with quick-serve restaurants, but this location made that experience the centrepiece of the design. Covered by a sweeping roof made of custom glass panels with amorphous silicon solar photovoltaics, the outdoor dining area is shaded and high-volume, low-speed fans modulate to maintain a comfortable environment.

The shaded environment is comfortable and maintains a similar operative temperature range as the indoor environment, even during some of the hotter temperature conditions. A shading study estimates that comfort is maintained 58% of the time between 6am and 6pm annually. The shaded area also helps precondition the natural ventilation air when that system is active.

The flagship McDonald’s restaurant was originally scheduled to open in April 2020, but this was delayed because of the onset of the Covid-19 pandemic. In July 2020, the restaurant opened for drive-thru service only. The commissioning team took advantage of this opportunity and evaluated and tuned control strategies for the kitchen ventilation systems.

The dining room opened to service in autumn 2020 and the natural ventilation features performed better than anticipated, as temperature and enthalpy ranges were expanded over design setpoint. (See Figure 1). Energy data is tracked live using a monitoring-based commissioning system and is performing better than design. Issues with inverter failures delayed net zero energy performance in the first year of operation. Currently the restaurant is seeking net zero certification through the International Living Futures Institute.

What is zero energy certification

The International Living Future Institute (ILFI) Zero Energy Certification is a third-party programme that enables projects to demonstrate zero energy performance.

It certifies, through an audit of performance data, that the building is producing net annual energy demand using energy from the sun, wind or earth.

All of the building’s energy needs on a net annual basis must be supplied by onsite renewable energy and no combustion is allowed. Certification is based on actual, not modelled, performance.

ILFI encourages projects to register early in the development process. Those taking part have access to a number of support resources.

Once registered, a project team can submit documents on the ILFI online certification platform. When construction is complete, documentation will be collected for the preliminary audit. After 12 consecutive months of performance data have demonstrated net zero carbon, the ILFI certification staff will review the information before passing it to an independent third-party auditor.

After certification, a case study is published on the project, with the intention of informing and accelerating other zero energy efforts throughout the world.

For more information, visit living-future.org

Benjamin Skelton is president at Cyclone Energy Group, which was the commissioning authority and energy expert for the McDonald’s project