The UK is making strides towards decarbonisation of its electricity grid, and heat pumps are playing a crucial role in this transition. Most new heat networks are now shifting towards all-electric heat generation, with heat pumps replacing gas combined heat and power (CHP) as the lead heat generation source.

However, there can be a significant increase in spatial requirements and capital expenditure when using heat pumps as the lead heat-generation source for heat networks, compared with gas CHP and gas boiler solutions.

To tackle this issue, I propose a hybrid approach that combines heat pump and thermal storage with electric boilers. Thermal storage increases operational flexibility of heat pumps and maximises the annual target heat fraction that can be provided by the heat pumps.

My research, How hourly load modelling is revolutionising heat pump and thermal store sizing in hybrid energy centres, was presented at the CIBSE ASHRAE Technical Symposium 2023, at the University of Strathclyde, Glasgow, in April (www.cibse.org/symposium).

If the heat pump is undersized and unable to meet the required target heat fraction, end users will see a significant increase in costs

It provides a ‘rule of thumb’ for hybrid energy centres to support designers and developers early in the design stages, ensuring that heat pump size and thermal storage capacity are optimised to achieve the required target heat fraction contribution, which is the proportion of the total annual network consumption that is provided by the heat pumps.

The heat pumps are sized to deliver the majority of the site-wide annual heat demand, with large thermal storage used to reduce the required heat pump size by storing heat during times of lower demand and using it during periods of higher demand. Electric boilers are sized to act as ‘top up’ during periods of peak load demand.

It is important to consider equipment sizing early on in the design stages, as such decisions could be constrained later by architectural layouts, floor plans and building elevations. This is where my research comes in.

Modelling heating and hot water use

In my research, an hourly load model was built, which aims to model the domestic hot water (DHW) and space heating usage that can be assumed for each hour across an entire year for any given development.

The model takes into account several inputs to investigate the impact of equipment sizing on the heat pump’s annual heat fraction contribution. These include: heat network heat losses; heat interface unit heat losses; DHW hourly profile; space heating hourly profile; and annual DHW and space heating loads.

To be as flexible as possible, the model allows for easy variation of building size, DHW, space heating loads, expected heat losses, and geographical location. By doing this, the impacts of these factors on heat pump and thermal store sizing can be easily understood and assessed. The final model was then validated against load profiles taken from operational heat networks to provide confidence in the findings of the research.

While there are many benefits to oversizing thermal storage, a key constraint will be the spatial requirement within the energy centre. This is especially key when comparing this with traditional CHP thermal storage, which operates at higher temperatures and, therefore, requires a smaller volume.

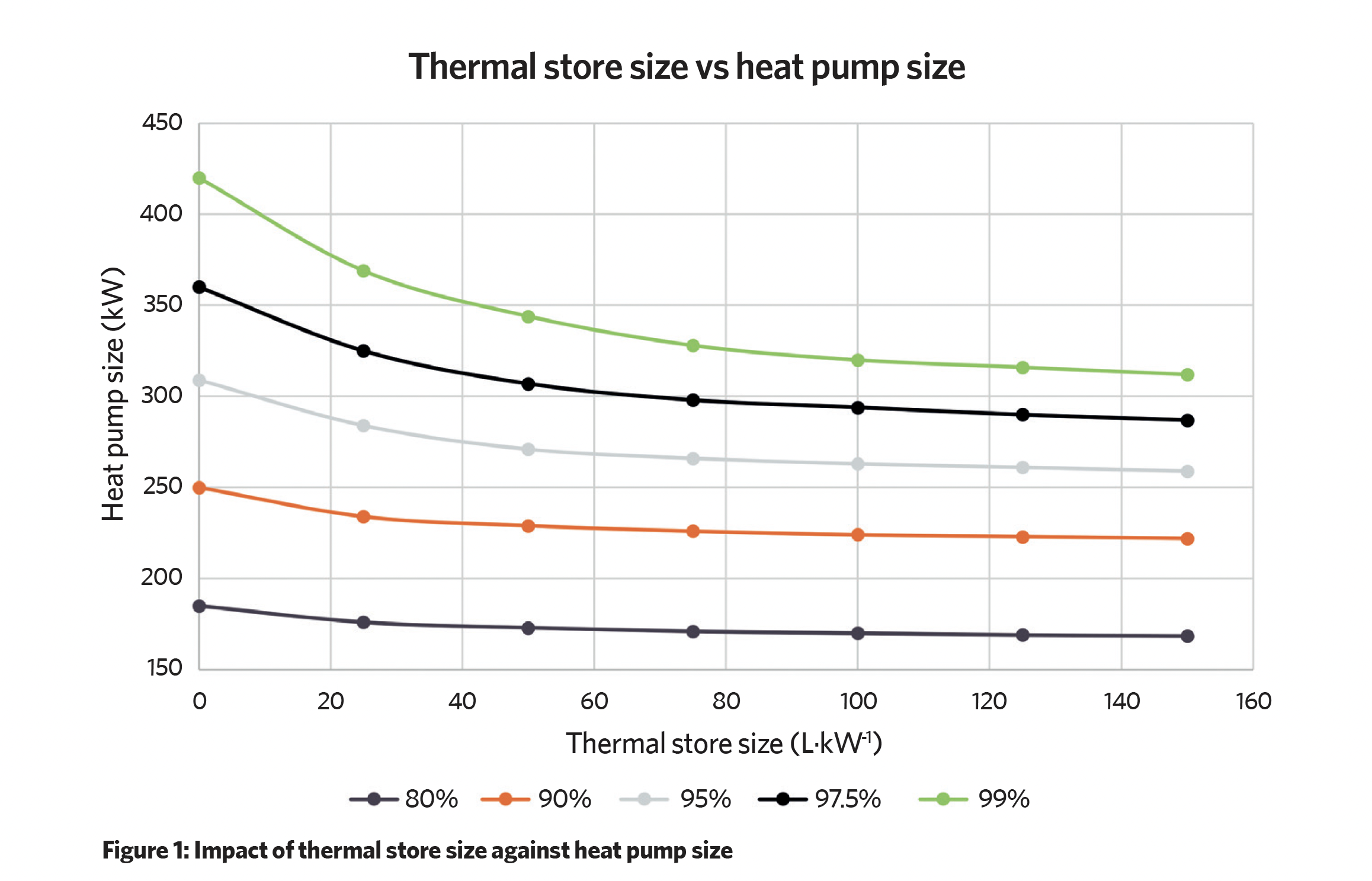

The hourly load model allowed the thermal storage size to be modelled against the heat pump to determine the point at which any increase to thermal storage will have minimal impact on reducing the heat pump size. The study found that, as a rule of thumb, thermal storage should be sized at 50-75L·kW-1, as shown in Figure 1. The percentages under the graph represent the annual target heat fraction contributions (for the heat pumps).

Because of the impact of the higher electricity tariffs compared with gas, it is critical that heat pump sizing is considered carefully. If the heat pump is undersized and unable to meet the required target heat fraction, end users will see a significant increase in their cost of heat because of the reliance on electric boiler top-up.

Equally, oversizing a heat pump presents a number of challenges, particularly when considering the spatial requirements against a gas CHP or gas boiler solution.

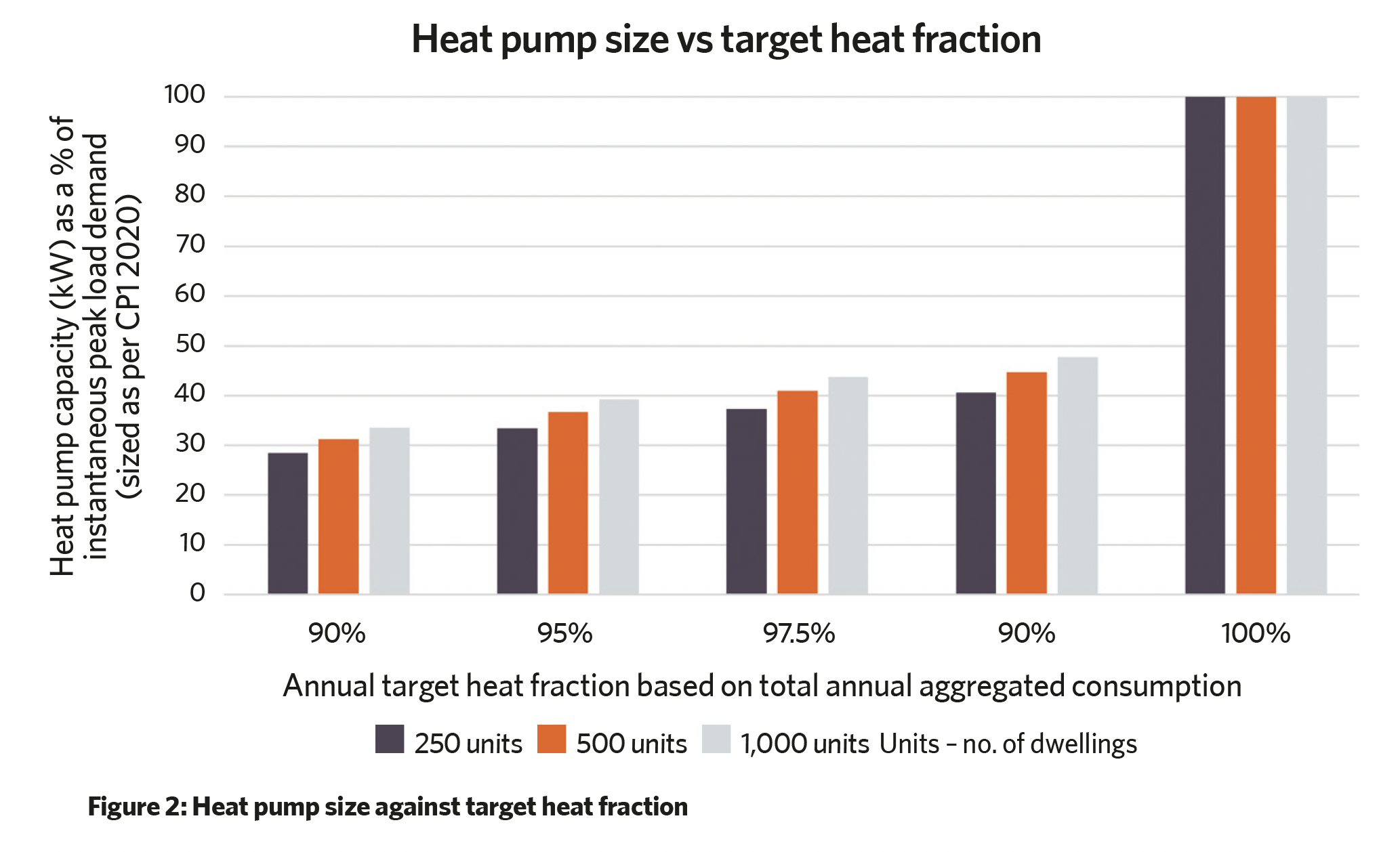

As such, the hourly load model was used to provide a rule of thumb for a given target heat fraction contribution as a percentage of the site-wide peak load. The findings demonstrate that a target heat fraction that is as high as 99% of the site-wide annual demand can be achieved by installing heat pump capacity of less than 50% of the peak load (see Figure 2).

A summary of the ‘rule of thumb’ findings are presented in Table 1. These findings provide a benchmark to support developers and designers early on in the design stages, to ensure energy centre sizing is fully considered until more detailed design calculations can be carried out at a later stage.

In conclusion, the research demonstrates that sizing a hybrid system for a heat network requires careful consideration of various factors, including the capacity of the heat pump and thermal store. Designers must take spatial limitations into account when estimating the required heat pump and thermal store size, to ensure these will not be constrained later in the design development, when the risk of undersizing will be critical.

The research provides targeted guidance for sizing heat pumps and thermal storage at concept design, in advance of detailed design, helping to pave the way towards more efficient and sustainable heat networks in the UK. To read the research paper, visit the ‘Research & writing’ page on FairHeat’s website: fairheat.com/research-writing