Bradford will be the UK’s City of Culture for 2025

Bradford will be the UK Capital of Culture in 2025 and the city council has another ambitious goal for the near future. It wants Bradford to be the UK’s leading clean-growth district, with a target for the city to be net-zero by 2038, 12 years ahead of the national target. A key element to helping the council realise these ambitions is a privately funded, low carbon district heating network that will the city’s businesses and organisations to decarbonise their heating and hot water.

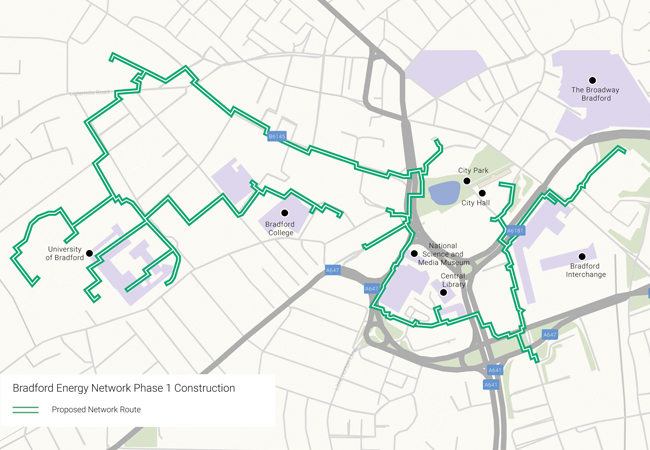

Bradford Energy Limited (BEL), a joint venture (JV) between 1Energy and sustainable infrastructure investor Asper Investment Management, has been established to construct and operate the Bradford Energy Network (BEN). In its first phase, the scheme will deliver up to 60GW of low carbon heat to existing buildings in and around the city centre, generated by a series of giant air source heat pumps (ASHPs) and distributed via a network of large, insulated underground pipes.

The £55m project is partly funded by a £20m grant from the UK government’s Green Heat Network Fund alongside private investment from the 1Energy/Asper Investment Management JV.

‘We are, we believe, the first heat network developer to bring private sector investment into the UK market to develop projects at city scale,’ says Jeremy Bungey, executive director 1Energy Group. ‘In addition to Bradford, we have three other heat networks in development, and several others are in the early stages of going for grant applications to help meet our ambition of 10 city-scale projects over the next few years.’=

1Energy’s commercial case for developing retrofit heat networks is based on the need for 22 million existing properties to stop burning gas for heating by 2050, when the UK has committed to be carbon net zero. ‘Really, there are only a couple of options available to decarbonise buildings: an individual building heat pump or connection to a heat network,’ explains Bungey. He says the heat network solution is by far the most economical way to access decarbonised heat, with ‘total whole-life costs around 30% cheaper than building-specific air source heat pumps’.

The government has yet to commit to a date for the phase-out of gas, so the challenge currently faced by 1Energy is persuading organisations to connect to the heat network. ‘The government has not yet said when gas will be banned or ruled out,’ says Bungey. ‘Without that clarity, what we’re trying to do is convince customers that it’s better for the environment, and for them, to connect now, and to be part of this decarbonisation agenda sooner rather than later.’

He believes the situation will improve once the government introduces heat network zoning to towns and cities (see box, ‘

To support the development of heat network zones in England, the government is taking forward the Energy Bill. The bill will provide powers for government to implement heat network zoning in England through regulations, which will include powers to designate city areas as heat network zones. Heat networks developed in these zones must be low carbon. Certain buildings and heat sources will then be required to connect to these heat networks within a specific timeframe. The government is currently working with 28 cities and towns to develop a methodology for identifying and designating heat network zones. The methodology will consider data such as location and building type, size and existing energy use, among other factors. Heat network zoning

Bungey will not say how many buildings have so far signed up for connection to the BEN because that information is ‘commercially sensitive’. However, 1Energy is talking to all the city’s major public sector bodies and colleges, its university, courts, and social housing providers, as well as the council about connecting its buildings and the town hall.

‘As part of our Green Heat Network Fund application, we have had letters of intent and we’re progressing those contracts now with a lot of public sector bodies,’ Bungey says. ‘We’ve also identified a lot of private sector organisations that are on the route and we are having discussions with those too.’

To engineer the Bradford scheme, 1Energy is working with heat network specialist FairHeat. The biggest engineering and economic challenge with the BEN is the need to develop a district heat network based on electric heat pumps, as opposed to a gas combined heat and power (CHP) engine.

‘CHP was very economical for district heating because of the power generation that those systems provide, but decarbonising

the Grid has meant we can no longer rely on that technology as a low carbon solution, so we have to look at using large-scale heat pumps,’ says Michael Ridge, principal engineer at FairHeat.

Perhaps the most difficult aspect of using heat pumps is pairing existing buildings, with their conventional radiator heating, with a low carbon heat network reliant on heat pump technology. ‘Most of the buildings we are dealing with are designed with classic 82oC/71oC radiator systems, whereas heat pumps like to generate low-temperature heat to improve their operating efficiency,’ says Ridge.

FairHeat’s solution for BEN is a hybrid system of heat pumps paired with gas boilers and a weather-compensated system. In winter, the primary pipework system will deliver heat at 80oC, generated through a combination of ASHPs and the gas boilers. The boilers will add ‘a little bit more temperature than the ASHPs for when system demand requires a higher temperature’, says Ridge.

Currently, the design is for 25% of the heat to come from the gas boilers, with 75% provided by the heat pumps. To achieve zero carbon, BEN will use green Grid electricity and offset carbon from gas usage.

Phase One of the heat network is expected to reduce emissions by 8,000 tonnes of CO2e per year

Adding weather compensation to the system ensures that high flow temperatures will only present when the weather is at its coldest. At higher external temperatures, the system flow temperature is reduced in line with a reduction in heat demand from the buildings.

‘We drop flow temperatures on the network in line with what the buildings actually need, down to 65oC in summer, which means we are maximising heat pump efficiency throughout the year,’ explains Ridge.

1Energy did look at having a lower system temperature, but the cost to customers of upgrading their heating system and enhancing the fabric of their buildings would have been prohibitively expensive. ‘We have had to drop a bit of system efficiency by raising the supply temperature, even with this weather-compensated approach, but it is far more beneficial to do this than to try to get customers to modify their systems, because the capital cost would have been too high to make it worth their while’.

Customers access the heat network through a plate heat exchanger, slotted into their existing plantroom as a replacement for gas boilers. Another major technical challenge is the need for the system to maintain a large temperature differential between system flow and return to further maximise heat pump operating efficiency.

‘We have to design the system to provide the flow temperature needed to keep the buildings warm, but a lot of these buildings also have really poor temperature differential control. So while we might have a flow temperature of 80oC, it might only drop to 75oC on the return, when our system would prefer a much lower return temperature,’ explains Ridge.

Rather than simply dictate the temperature differential that a customer’s system has to deliver, 1Energy is funding FairHeat to undertake surveys of potential customers’ buildings and heating systems. These help 1Energy, which will be operating the network, and its customers understand the interventions needed to increase the temperature differential, and the potential cost of these works. Armed with building-specific knowledge, 1Energy and FairHeat can support customers with their Public Sector Decarbonisation Scheme grant applications.

‘It’s been a significant investment in time, but we simply wouldn’t have got to where we are in terms of helping building owners figure out the best way to decarbonise and connect to our network,’ says Ridge.

For the BEN, the ASHPs will be installed in a purpose-built energy centre. The units will be split, with dry evaporators mounted externally on the building’s roof and the decoupled 2MW compressors and condensers housed on the energy centre’s ground floor, along with the gas boilers. The compressors are modular so the system can be expanded as demand increases over time, up to 8MW. Refrigerant will be a blend of CO2 and a hydrocarbon.

The proposed energy centre in Bradford

Externally, the energy centre is also home to three large thermal storage tanks, of almost 600m3 capacity in total. ‘The more thermal storage the better in terms of flexibility,’ says Ridge. As well as allowing 1Energy to charge the stores when electricity is cheap, the large thermal store means the heat network can reserve a portion of storage uncharged, so the energy centre can respond to requests from the Grid to take power by running the heat pumps even when customer demand for heat is low. ‘The bigger the thermal storage, the more opportunity we have to play to those different market opportunities,’ says Ridge.

Grid balancing is not included in 1Energy’s business case, says Bungey. ‘If we can take advantage of it, that would be great as an extra, but it’s not core to what we’re doing.’

1Energy is also looking to take advantage of waste heat sources to top up the system. ‘Because we are self-sufficient in heat provision, we can supplement the system with waste heat by paying appropriate prices for it,’ Bungey explains.

Being self-sufficient in heat is also key to providing a resilient supply of heat, because customers are used to having a reliable gas supply. ‘We are in control of the heat pump heat source and the back-up provided by the gas boilers and thermal stores; these can be supplemented with waste heat as and when opportunities arise,’ says Ridge

He adds that this approach has been adopted successfully in Scandinavia, where a network will start off with a strategy in terms of distance, customers and capacity, but then additional heat sources will feed into that over time, to ensure a lot more flexibility in how heat is provided.

‘We can’t look at that end goal as our starting point, but we are really excited about that part of the journey where our pipes go past someone’s front door and they ask us about the network. It’s about getting the initial project off the ground and then seeing it grow from there,’ says Ridge.

Currently, the 400mm-diameter flow and return pipes to deliver low carbon heat from the energy centre to buildings in and around the centre of Bradford are being buried beneath the city. Eventually, a network of pipes will run from the energy centre in the west via two main spines that will deliver heat to where it is required.

A challenge with the installation that 1Energy is working to overcome is the limitations of the supply chain in the UK, which, Bungey says, is populated by a number of mostly small players.

Pipework is being installed beneath the city’s streets

‘What we’re trying to do is work with those smaller players to help develop the market and the supply chain – which we need to do because we are looking at installing networks in 10 cities at this scale,’ he adds.

‘Each heat network package is worth tens of millions of pounds, which is often larger than the entire turnover of some of these organisations, so we have to work with them to share risk and to help them develop.’

The system is designed to only supply heat; there is no cooling planned for Bradford. ‘Very few of the existing buildings we will be connecting to have a significant cooling demand, so the network is all about heating and hot water,’ says Ridge. However, Bungey adds that there ‘might be an opportunity to do something’ in other cities depending on the cooling demand and the business case for investment.

Green electricity will be used to power the heat pumps. This makes the carbon content of heat supplied to customers about 59g CO2e/kWh, which, Bungey says, is about a ‘75% carbon saving against a gas boiler’.

Clearly, heat networks have a role to play in helping the UK achieve its net zero targets. The Climate Change Committee has estimated that around 18% of UK heat – including domestic, commercial, industrial and public – could come from heat networks by 2050, a significant increase on the current figure of around 2%. In Bradford, phase one of the heat network is predicted to reduce emissions by approximately 8,000 tonnes of CO2e per year. 1Energy is aiming to have heat on in April 2026, which will take Bradford a step closer to its net zero goal.