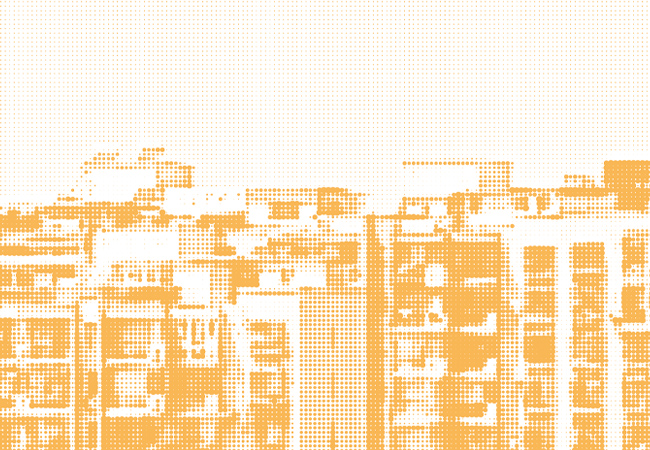

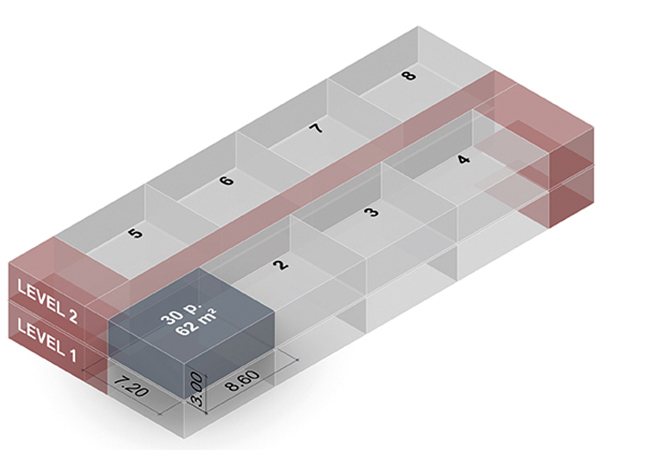

Figure 1: Hybrid ventilation system (S1)

The pilot version of the UK Net Zero Carbon Buildings Standard confirms the urgent need to mitigate embodied carbon in addition to operational emissions. While there is growing consensus in the industry about the importance of addressing this issue, lack of quality data makes it challenging to make informed decisions.

CIBSE TM65 Embodied carbon in building services outlines the need to assess the embodied carbon of BSE systems and provides calculation methodologies. It is particularly useful for assessing ventilation systems, often underestimated because of missing Environmental Product Declarations. The mitigation potential is evident: large units in ventilation systems can be made of up to 95% carbon-intensive metals (for example steel, aluminium and iron).

In educational buildings, this sharpens debate within design teams between active strategies and passive strategies that make use of natural ventilation fundamental principles. In classrooms, the latter is not often considered, and is criticised for the heat loss from exhaust air and the lack of indoor air quality (IAQ) control.

However, Building Bulletin 101 reminds us that ventilation is not a simple matter of active versus passive systems; there is also a wide range of intermediate solutions. Hybrid systems explore ways to reduce operational and embodied carbon by making the most of both worlds.

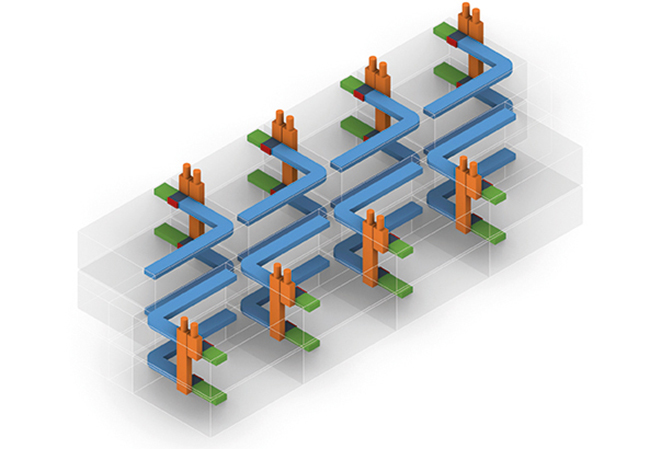

This study compares two ventilation systems, both with heat recovery and CO2 sensors, to address the limitations of passive strategies. The hybrid system S1 (Figure 1) benefits from a wind-driven roof cowl and buoyancy effect through a vertical chimney. An intermittent active fan controlled by CO2 sensors maintains IAQ and addresses wind fluctuations. The active ventilation system S2 (Figure 2) represents ‘business as usual’, with conventional central air handling units (AHUs) and dual rectangular steel ducts.

Figure 2: Active ventilation system (S2)

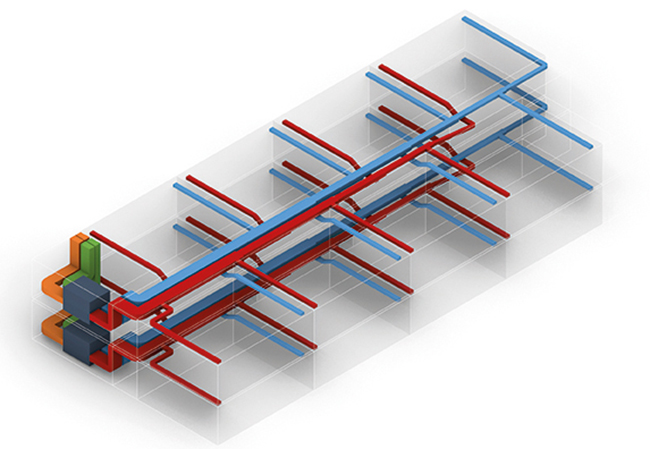

The study aims to assess the life-cycle embodied carbon of the two systems over 60 years. As the buildings differ in geometry – and for comparison purposes – both systems are sized in 3D for a hypothetical building designed with Building Bulletin 103 Area Guidelines for Mainstream Schools.

The occupancy is 30 people for a floor area of 62m². As some systems serve several classrooms and others have a vertical distribution, the hypothetical building is composed of two levels of eight classrooms, separated by a corridor. This hypothetical building is the basis for comparison and may represent a small school or facility wing (Figure 3).

Figure 3: Hypothetical building used to compare ventilation systems

System components are listed and measured, and the TM65 basic calculation is used. It requires simple information on the material breakdown, product weight, refrigerant type and quantity, equipment capacity, product service life, and repairs.

A scale-up factor is applied according to the complexity of the product, to account for all modules. A buffer factor is applied to reflect the simplicity of the calculation. For this early-stage analysis, refrigerants, operational energy and water are excluded, to focus on air supply for ventilation only. The relevant embodied carbon coefficient is used for the assessment of each material.

Results

The results are calculated in kgCO2e and shown per gross internal area (GIA). Overall, the hybrid system S1 emits a quarter less embodied carbon than the active system S2 over 60 years.

Although the number of components is multiplied by the number of classrooms in S1, S2 is composed of very heavy units with a short lifespan. In addition, the glass-wool ventilation ducts in S1 are almost half as long and half as carbon-intensive as the galvanised ducts in S2.

The number of component replacements has a significant impact on results. Pessimistic and optimistic lifespan scenarios arose from interviews with design professionals and are used to highlight the potential deviations from CIBSE Guide M: Maintenance engineering and management.

This raises the question of how accurate assessment assumptions are compared with the actual lifespan of building components yet to be measured.

Operational energy emissions are not included, which would worsen the results of S2, with a specific fan power expected to be higher than S1.

It is important to note that this study considers two specific systems from case-study buildings, and the results cannot be generalised as typical values for types of ventilation strategies.

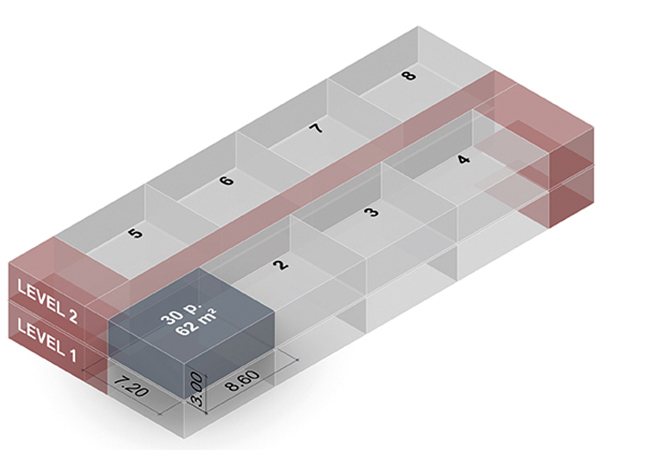

The review of the two ventilation systems highlights the benefits of the hybrid ventilation system (Figure 4). Unlike a mixed-mode system, which uses two systems in parallel, the hybrid system combines them, limiting the quantity of materials used.

Figure 3: Hypothetical building used to compare ventilation systems

However, the analysis also reveals the importance of ensuring that the fundamental passive principles are not compromised by this combination. While the roof fan must be able to be driven by wind, it should also be large enough not to reduce the stack-effect potential.

This reminds us that the debate is not binary between mechanical and passive ventilation, and that fully active systems are not the only solution. While the drive for net zero carbon pushes designers to seal the building envelope and reduce air permeability, the industry should also take into consideration the negative effects on indoor air quality.

The improvement of filters, while effective, also requires greater amounts of energy to turn the fans. More research is needed to explore the environmental impact of HVAC systems and to enhance the quality and quantity of data available.

However, some recommendations can already be made. First, ensure the good quality of outdoor air, as it directly impacts IAQ and occupant health. Second, optimise the potential for passive strategies in natural or hybrid ventilation systems, to significantly reduce reliance on mechanical components, thereby reducing operational and embodied carbon emissions. Where mechanical ventilation is necessary, it should be well sized to meet the needs of the space. A layout that minimises the quantity of ducts can further reduce material use and carbon emissions. Finally, products should be selected with lower embodied carbon and with components that have a long service life.

The findings highlight the importance of combining passive and active strategies, the need for robust embodied carbon data quality, and the lack of feedback on the real-life expectancy of building products.

This paper was based on one presented at the CIBSE IBPSA-England Technical Symposium 2025 that offers valuable insights into the potential of hybrid ventilation systems to reduce embodied carbon emissions in HVAC systems, contributing to the wider goal of achieving net zero carbon buildings by 2050.

About the author

Mat Naccarato is a senior consultant at Savills Earth