Aidan Kelly

Ever since the invention of the ductulator, building services engineers have sought to automate the time-intensive design processes.

Why? The cynic may say that it’s so we can finish our work a day early, or deliver more projects and profit within a given timeframe. But the honest answer, I believe, is something more fundamental: engineers don’t want to spend their time doing repetitive processes.

They want time to be spent creatively, critically and quantitively assessing different approaches, and integrating lessons learnt from past projects with new technologies for an optimal solution, rather than spending days calculating ductwork resistance.

If we want to develop artificial intelligence (AI), however, we cannot do so in isolation. Collaboration can help to break open silos, bringing together new ideas and skill sets.

So, how far have we come since the ductulator? OK – let’s consider some examples (there are many more available):

- For many, Revit and its in-built programming tool, Dynamo, have long since banished the administrative processes of project set-up and drawing creation to yesteryear, and allow engineers to design in three dimensions.

- Parametric environmental analysis tools, such as Honeybee and Ladybug, have turbocharged early-stage concept design and optioneering. With a simple 3D model, you can now run multi-objective optimisation routines at the click of a button, to assess different designs and then have the option to produce high-quality visual outputs.

- Generative design tools, such as Space Allowances, will take a few significant MEP load inputs and generate 2D and 3D drawings of plantrooms, along with plant schedules.

- Life-cycle carbon assessment tools for BIM applications streamline the process to such an extent that embodied carbon can be quantified much earlier in the design phases, and used to make key design considerations to reduce the environmental impact of the scheme.

- The new TM65 embodied carbon calculation tool will help more manufacturers to calculate the life-cycle carbon of their products, taking into account not just manufacturing elements, but also transport to site, parts replacement and refrigerant leakage.

This list is not exhaustive, but hopefully provides a peek as to what is happening in our industry.

One issue, however, is that all too often automation occurs in silos – great work is done by a self-selecting few, and shared with a limited audience. As a result of a lack of promotion, or companies keeping their aces tucked up their sleeves, very similar great work is done by another small cohort to another small audience, reinventing the wheel.

All too often, automation occurs in silos – great work is done by a self-selecting few, and shared with a limited audience

Autodesk University, CIBSE’s Technical Symposium and the Build2Perform events and the Society of Digital Engineering (SDE) do a great deal to provide a platform for innovators to present their latest automations. However, the missing ingredient – and the one that I believe can help supercharge automation – is collaboration. This can be done internally, at the company level, or via inter-company working groups or hackathons.

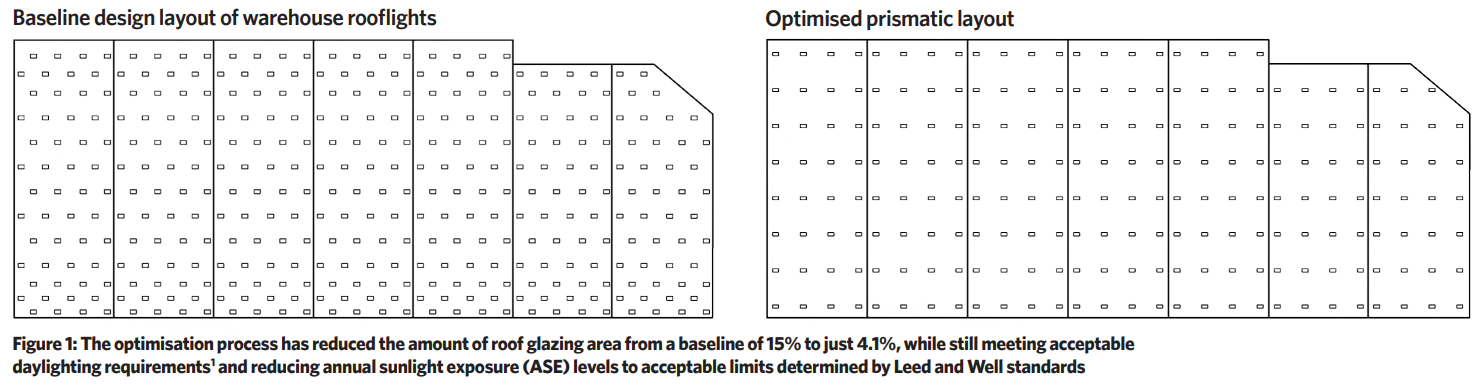

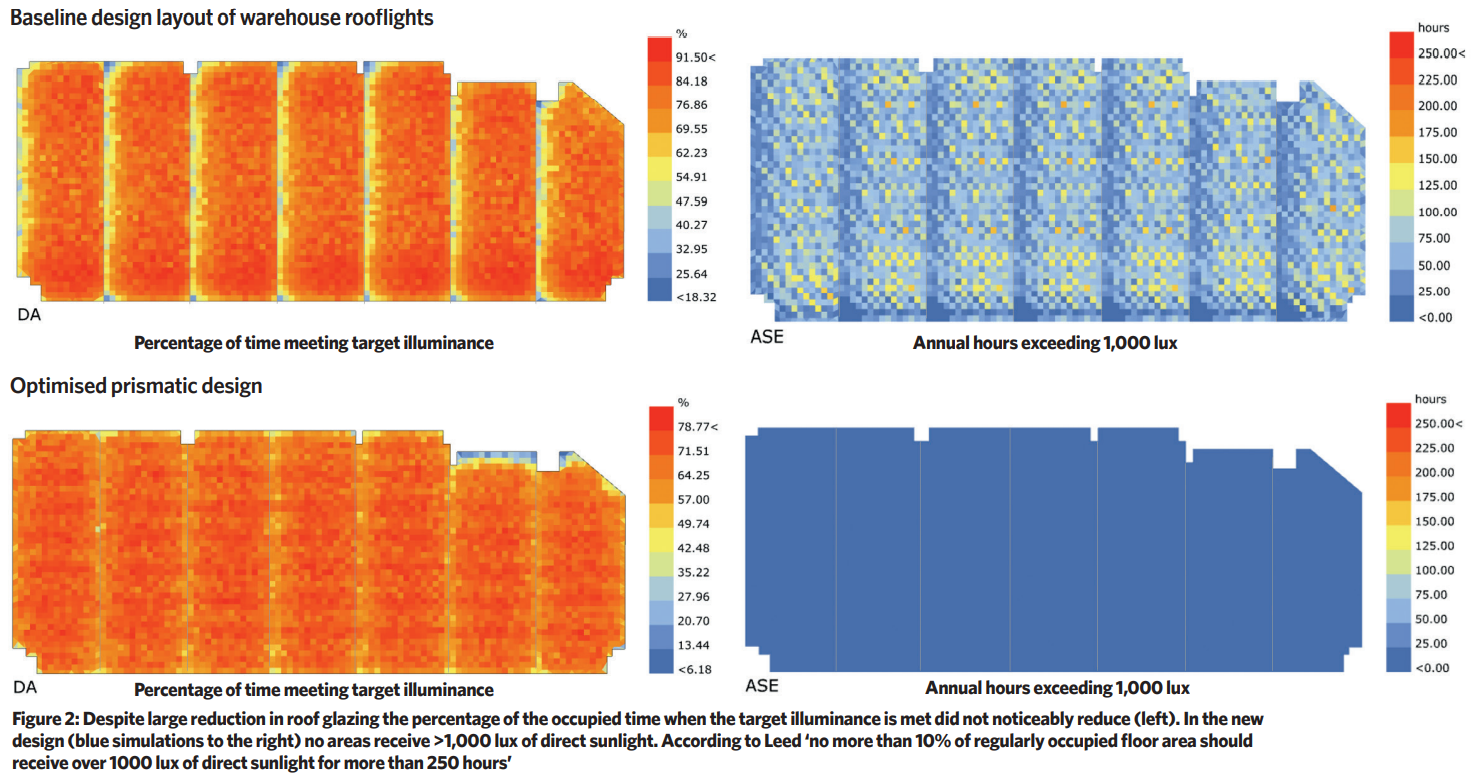

At XCO2, we have created the XCO2 Lab, an open group to identify time-intensive processes ripe for automation solutions. Through identifying problems, the lab creates an opportunity for interdisciplinary collaboration – solutions can come from anywhere: from graduates with machine learning experience, to senior engineers armed to the teeth with Visual Basics for Applications scripts. Previous automation examples include a daylight simulation project for a warehouse that aims to arrange and minimise glazing area, minimising overheating risks while maintaining high levels of daylight autonomy (see Figure 1 and 2).

CIBSE’s SDE has many working groups bringing together engineers from many companies and the CIBSE membership. I chair the SDE Digital Innovations Working Group that discusses and develops open tools that could be rolled out to CIBSE members. Recent examples include the TM65 tool, and future developments aim to automate the embodied carbon calculation of MEP distribution.

Hackathons are the final piece of the puzzle. A concept borrowed from the world of software development, it is an event that invites teams to come together to tackle a problem within a short timeframe to create functioning software tools and improved workflow automations.

The time limit puts the teams under pressure, in the hope that pressure leads to diamonds. At the SDE, we held our own hackathon event – the ‘One Day Design Challenge’ – at which teams had a single day to use automation tools they developed to produce as many concept design deliverables as possible bit.ly/CJMar22AI

With an ever more digitally literate workforce, there will be a growing appetite for events aimed at engineers. There are already a host of problems that could benefit from the bringing together of great minds from across the industry. Seeing what these engineers could rustle up in a hackathon could be an important leap in innovation.

How can we leverage AI into the design or construction process? How do we bridge the gap between design/construction models and digital twins? How can we integrate modern methods of construction at the early design stages? The list could go on and on and on!

So, with collaboration cracked, we would hope to see a snowball effect, where greater awareness results in automations rolled out across the industry to become standard practice, where existing automations are employed to build bigger and better ones. The hope is that more internal labs and hackathons spring up.

As the balance of power shifts from PowerPoint and Excel to code, prediction, data analysis and dashboards, employing automation will no longer be a chance to get ahead, but a choice to prevent falling behind.

You can get involved in this transformational world of automations by joining up with the SDE.

References:

- Farah Husayni, Parametric Modelling for Climate Based Daylight Analysis – A Case Study of Industrial Warehouses, XCO2, 2020 Technical Symposium poster bit.ly/3jbxj1i