Credit: iStock – Sucharas wongpeth

Providing the outdoor air to ventilate buildings requires large amounts of energy and a significant amount of space. Failing to heat or cool this supply air will quickly result in complaints, but if the air being supplied to the building is polluted to the point that it would negatively affect people’s health, it is unlikely occupants would notice immediately.

Air filters are a critical part of a ventilation system, and basic, low-grade filters can protect the internal components of that system. With an increasing focus on health and wellbeing in buildings, however, filters are increasingly being selected according to the level of outdoor pollution at the building’s location, not via rule of thumb selections from the air handling unit manufacturer. Fortunately, enough standardisation and guidance has been released in the past few years to make it easier for designers and building operators to select appropriate filters.

In 2016, ISO 16890-1 Air filters for general ventilation introduced a new global standard for testing and classifying air filters based on particulate matter (PM) size (PM1, PM2.5 and PM10). It outlines 49 new classifications, replacing the EN779:2012 standard and its nine grades, such as F7 and G4. ISO 16890 is used worldwide, except in the US, where MERV (minimum efficiency reporting values) are employed.

In 2018, the European industry association Eurovent produced the guidance document 4/23 Selection of EN ISO 16890-rated air filter classes for general ventilation applications (bit.ly/CJEV423). This advises on appropriate levels of filtration based on outdoor pollution and the use of the building.

These two documents provide a comprehensive methodology for selecting particulate filters to try to meet the 2021 World Health Organization (WHO) limits for PM2.5 and PM10.

Another key development in recent years has been around the energy rating of filters. Resistance to airflow and the subsequent impact on specific fan powers is an often overlooked aspect of a building’s energy consumption. HVAC systems typically account for 38% of a building’s energy consumption1, and 16% of energy usage is typically attributable to the resistance of filters2.

Eurovent 4/21 Energy efficiency evaluation of air filters for general ventilation purposes (bit.ly/CJEV421), published in 2019, gives ratings for energy consumption of particulate filters. Filters are graded from A+ (top 5% most efficient) to E (bottom 50% for efficiency). While a filter with basic construction may meet the required filtration efficiency, if it has a low dust-holding capacity and quickly increases in resistance as it loads, it will be penalised by this testing methodology.

The cleaning performance and energy efficiency of filters has often been overlooked by designers and building operators

More sophisticated low-energy filters are more expensive than basic ones, but prioritising low capital expenditure will significantly increase operating expenditure. Eurovent 4/21 has made filter energy consumption transparent, allowing for easier whole life cost calculations and supporting sustainability focused decision-making. As there can be a vast difference in energy performance for a similar particulate filtration efficiency, this should be a focus of sustainability engineers. Low-energy filters should be a key component of an M&E design.

ISO 10121-3 Test methods for assessing the performance of gas-phase air cleaning media and devices for general ventilation was released in 2022. Until this point, there was little guidance around the effective use of gas-phase or molecular filters, often referred to as carbon filters.

ISO10121-3 rates the filters’ single-pass efficiency at removing a range of ‘challenge gasses’: ozone (O3), nitrogen dioxide (NO2), sulphur dioxide (SO2) and toluene. The first three are common outdoor pollutants, while toluene is a representative volatile organic compound (VOC). VOCs can be found in outdoor air, particularly in cities, but are more often considered an indoor pollutant, as they are readily released by solvents, paints and building materials.

Molecular filters require a contact time between pollutants and the filter media. If air passes through the adsorbent media too quickly, it will not be effective. This is related to the velocity of the air and the thickness of the media. The physical structure of the media also plays a significant part in the finished filter’s effectiveness.

Just as the efficiency of gaseous pollutant removal is graded, so is the effective lifespan of ISO 10121-3-rated filters. Combined filters with a tiny amount of impregnated carbon have been marketed as an effective solution for removing gaseous pollutants for as long as the particulate filters last (6-12 months). The tiny amount of carbon in these filters could become saturated – and therefore ineffective – within a few weeks in certain environments with high gaseous pollutant levels.

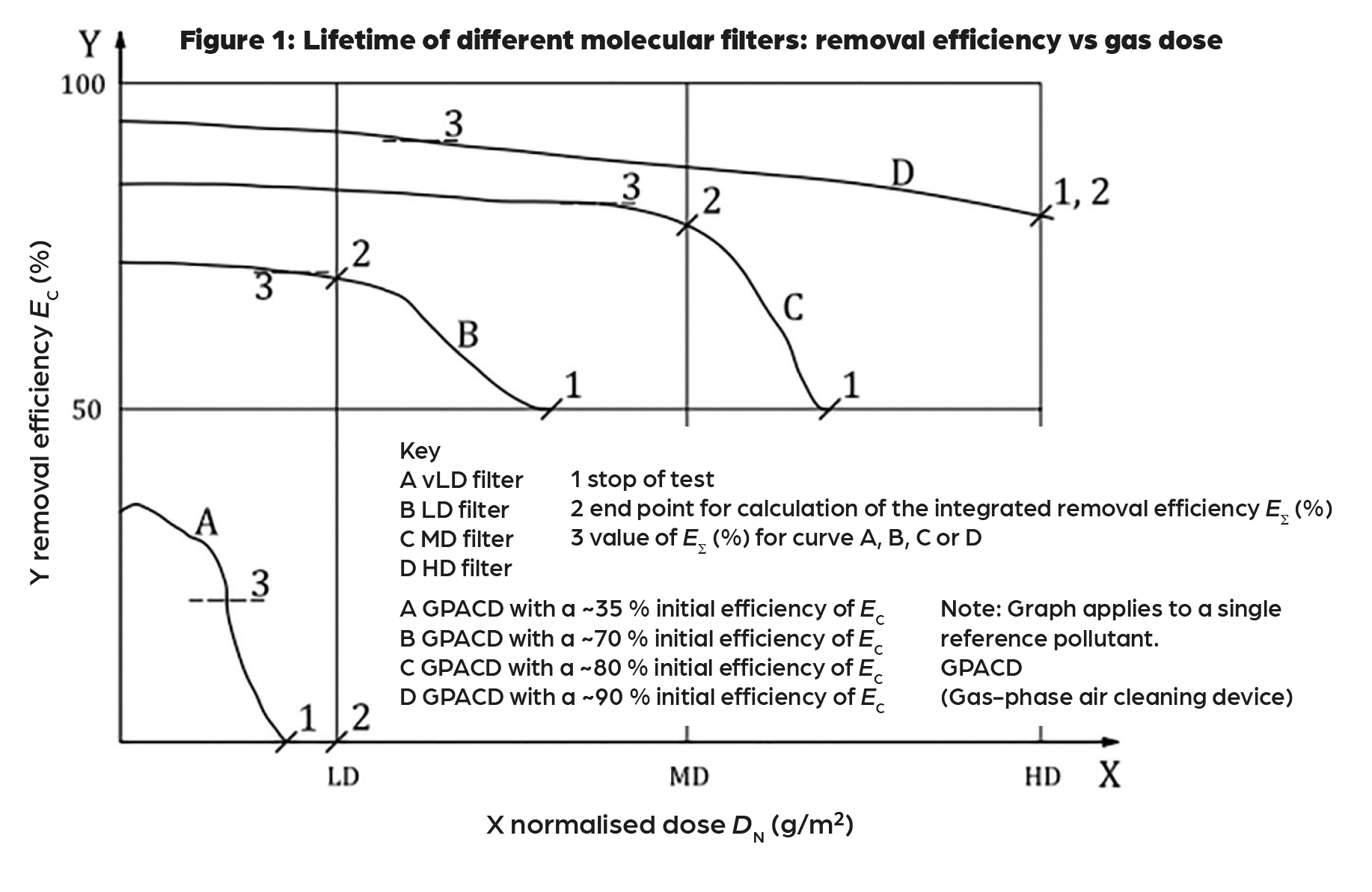

To address this, ISO 10121-3 categorises molecular filters as heavy duty (HD), medium duty (MD), light duty (LD) and very light duty (vLD). There is a large difference between these ratings (see Figure 1). For example, if a HD molecular filter has an effective lifespan of 80 months, an MD filter – for the same pollutant load – would last eight weeks, and an LD filter just two weeks. A vLD categorisation denotes that the filter performed below the 50% effectiveness required to meet the LD classification.

A filter may have different performance characteristics according to the challenge gas used in the test. For example, a filter could be HD 70 for toluene and LD 55 for SO2.

In January 2025, Eurovent 4/26 Selection of molecular filters for supply air for general ventilation rated according to ISO 10121-3 was released (bit.ly/CJEV426). In a similar vein to Eurovent 4/23, this aims to guide specifiers and facilities management teams in the selection of appropriate filters according to building usage and local outdoor air pollution levels.

Eurovent 4/26 advises how to select filters to comply with 2021 WHO guidelines (AQG) according to the outdoor air categories (ODA) and supply air categories (SUP) in EN 16798-3. It includes selection tables recommending appropriate efficiencies for specific ODA and SUP requirements.

The cleaning performance and energy efficiency of filters has often been overlooked by designers and building operators. There is now enough standardisation and guidance available to enable decisions to be made that reduce energy consumption and, more importantly, protect the health of building occupants.

About the author

Adam Taylor MCIBSE is CEO at ARM Environments and chair of the BESA IAQ Group

References:

1 A review on buildings energy information: trends, end uses, fuels and drivers, November 2022, Energy Reports, bit.ly/CJTrER22

2 Klimatkatalysatorn 2021, Svensk Ventilation (Swedish Ventilation Industry Association), bit.ly/CJCCSV21