This CPD article aims to examine the practical assessment and certification of lighting fixtures that focuses on their compatibility with the principles of the circular economy to foster product sustainability, stimulate design improvements and innovation, and establish trust among consumers.

Reportedly, there are around two to four million tonnes of lighting waste generated globally each year. This includes incandescent, fluorescent, and LED lamps, as well as lighting fittings and luminaires. Many of the discarded lighting products ultimately end up in landfill or incinerators, where they can release harmful pollutants into the environment.

There are a number of things that can be done to reduce the amount of lighting waste generated, and one key aspect is ensuring that products are holistically as sustainable as practicable. By ensuring that they are compatible with the circular economy, they will preserve value in the form of energy, labour, and materials.1 And, as reiterated in the recent review paper by Grigoropoulos,2 which examines the life-cycle assessment of luminaires, the optimal pathway to enhance sustainability primarily lies in the initial design stage of lighting products.

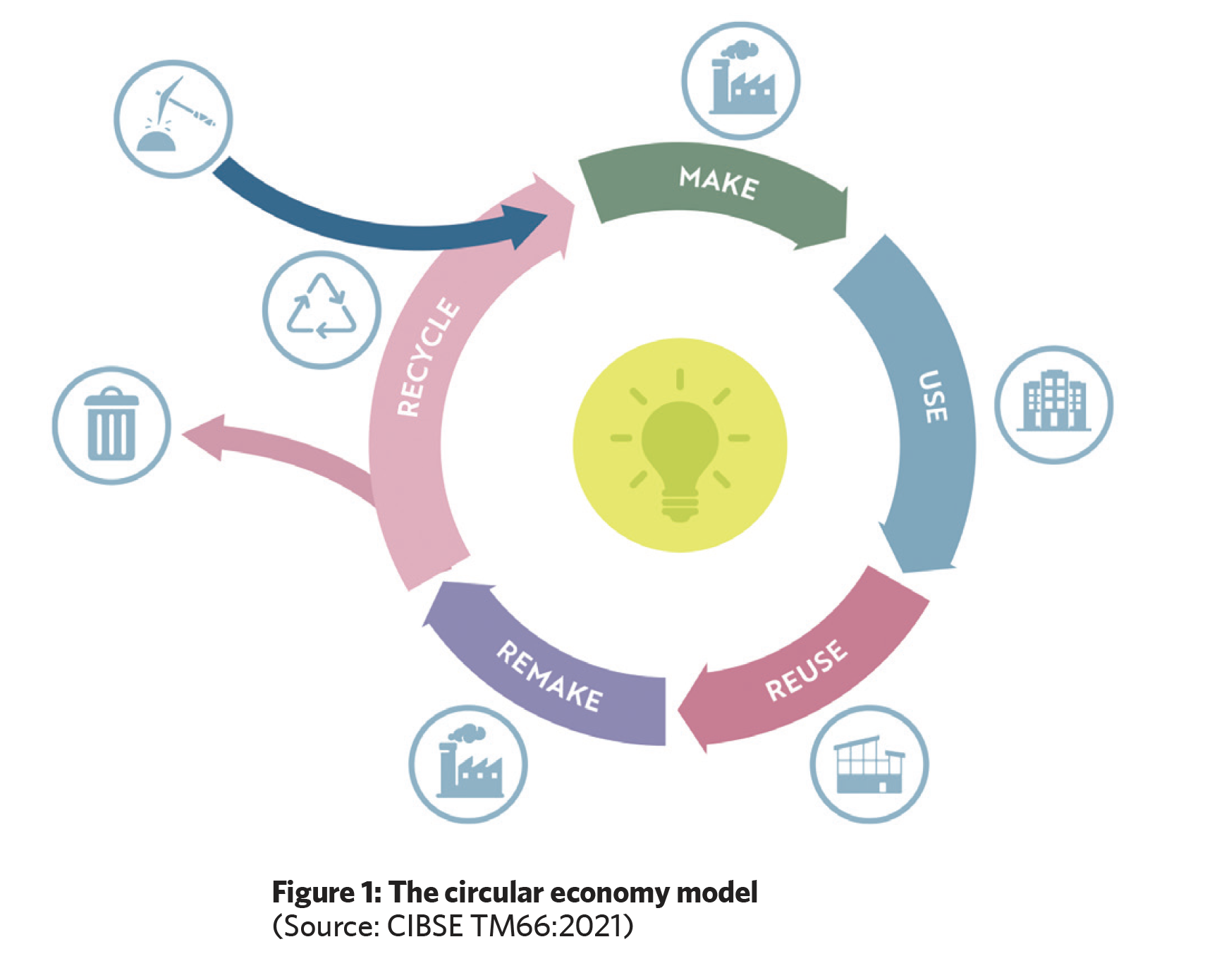

A circular economy, as illustrated in Figure 1, provides an alternative to the traditional linear economy, in which products are made, used, and then discarded. Products, components and materials are kept in circulation for as long as possible, by designing for durability, reuse, remanufacturing, and recycling, thereby reducing waste and pollution.

- Specific examples of how the lighting industry can adopt circular principles include the following:

- Evolving products that use less material while delivering life-cycle sustainability

- Designing products that are easy to disassemble and remanufacture

- Selectively employing materials and methods with low embodied carbon

- Prudently recycling materials back in to the manufacturing process

- Offering accessible take-back programs for used lighting products

- Educating consumers about the importance of recycling and reusing lighting products.

As explored more fully in CIBSE Journal CPD 204,3 CIBSE TM65 Embodied carbon in building services: a calculation methodology provides an introduction to whole life carbon and embodied carbon, and notably also includes a method to assess the embodied carbon of MEP products where a manufacturer has not already developed a BS EN 15804:2012+A2:20194-compliant environmental product declaration (EPD) for their product.

The embodied carbon calculations in CIBSE TM66 Creating a circular economy in the lighting industry builds on the methodology outlined in CIBSE TM65. It provides a background to circular economy principles, and sets out the drivers and barriers specifically for lighting products. A common benchmarking tool is introduced that aims to overcome the diversity of results from the individual methods that are presented by lighting manufacturers employing their own bespoke techniques, which make it challenging to compare claims of sustainability across the industry.

TM66 is designed to balance complexity with effectiveness and usability but is very reliant on the user’s level of knowledge, and their interpretation of the supply and manufacturing supply chains for their product. Case studies are included that demonstrate how some of the principles of a circular economy have been successfully implemented by lighting manufacturers.

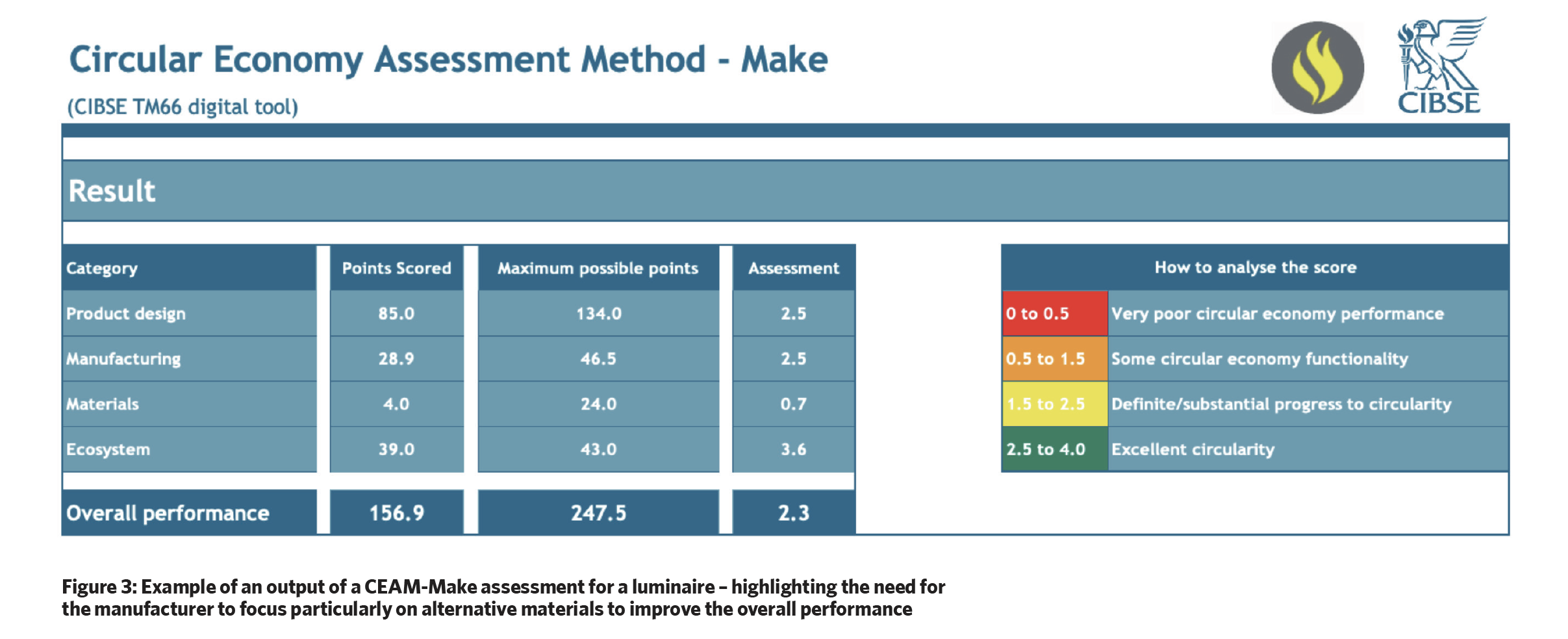

The Circular Economy Assessment Method (CEAM) illustrated in TM66 employs accompanying Excel spreadsheet tools to steer manufacturers towards improved product circularity, as well as providing specifiers and clients with an understanding of the questions they need to ask of their suppliers. The tool, CEAM-Make, employs an Excel spreadsheet comprising 66 questions under four tabs – product design; manufacturing; materials; and supporting ecosystem – to assess a luminaire in terms of its circular economy performance.

By adding the specific answers to the questions, products are given a rating of zero to four, with the spreadsheet tool allowing iterative inputs to encourage and enable manufacturers to improve the rating. The zero baseline for a product indicates ‘very poor circular economy performance’, with the intent of the tool being to encourage and enable products and support ecosystems that score three or four, indicating ‘excellent circularity’. The CEAM-Make spreadsheet, as shown in the example in Figure 3, provides a final rating – in this illustrated case, highlighting that the manufacturer needs to particularly reconsider some of the materials that are being employed in order to improve the circularity credentials of the product.

Accurate completion of CEAM-Make relies on the input of fair and reasonable values backed by hard evidence, with the sheet’s guidance notes warning that there is ‘no wishful thinking or generalised statements allowed – evidence must be specific and supported’. The end result of the process is a self-certified metric of luminaire circularity.

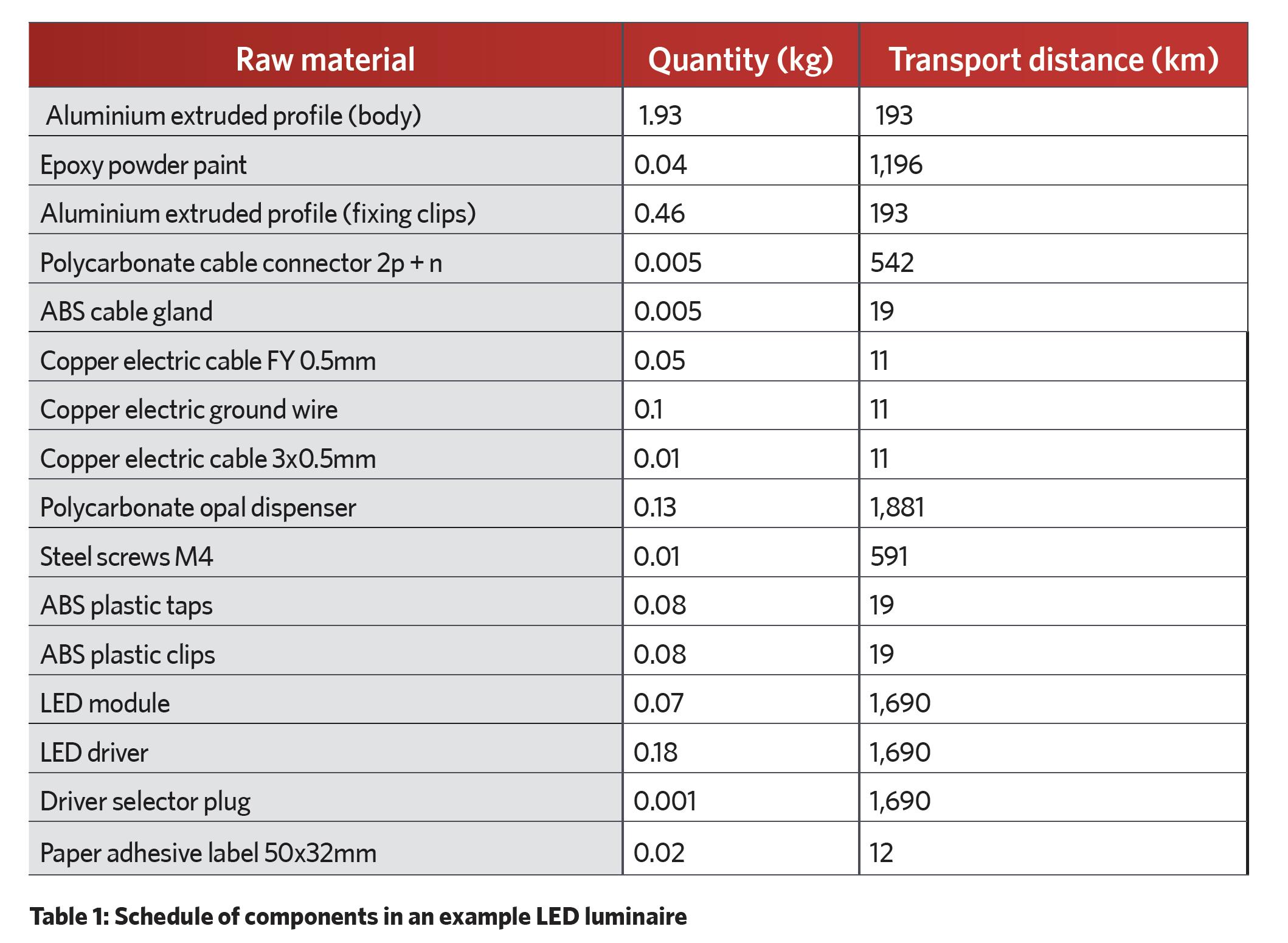

The recent case study5 by Albu et al explored the life-cycle assessment (LCA) of an example LED suspended luminaire (as shown in Figure 2) designed for use in office, education, residential and retail applications. This comprised an aluminium LED polyurethane powder-coated housing, a driver power supply with electric protection, an LED linear module with electronic control system, a polycarbonate opal diffuser, and various connections and fixings (electrical cables, connection plugs, and screws). For a seemingly simple luminaire there is a reasonably extensive schedule of components, as shown in Table 1, many being sourced at some distance from the final manufacturing location. Albu and his co-authors employed proprietary software that draws on many embodied carbon resources (including the freely downloadable ICE database6) to undertake the LCA. Without detailed knowledge of the manufacturing process of the many specific components, it can be difficult to determine the level of confidence in the provenance and reliability of data for some components. Reasoned, and evidenced, judgments will be required to assess the product data, especially the questions about manufacturing and materials on the CEAM-Make spreadsheet. A significant amount of investigation and evidence-gathering may be necessary to maintain a credible process. However, this can be avoided if the components themselves have an accredited EPD or similar. Once the initial investigation has been conducted for a product, it is likely that the same data may be repurposed by the manufacturer for other luminaires in the product family.Pinning down luminaire component data

There is an additional, associated spreadsheet that provides a short-form ‘triage tool’ for a designer, specifier or engineer – CEAM-Specify. The four tabs provided in Make are collapsed into one in Specify, allowing the quick comparison of two or more products.

The CEAM has been created to improve sustainability in the lighting industry and, as such, should be used to assist in the accurate assessment of circular economy performance. It is a rigorous assessment tool that helps manufacturers to identify and improve the environmental impacts of their products. This can give manufacturers greater confidence that their products are truly sustainable and that they are meeting the needs of their customers. The tool is not intended to be used to ‘game’ the process in order to misleadingly inflate the circular economy performance scores.

The Lighting Industry Association (LIA) and CIBSE joined forces to develop the TM66 Assured Product Verification Scheme,7 to provide independent verification of lighting manufacturers’ circularity claims, as well as to ensure accuracy and maintain credibility. Lighting manufacturers that participate in the TM66 Assured scheme can have their CEAM-Make self-certified assessment independently verified to assure the accuracy, objectivity, and consistency of the luminaire circularity score. The assurance scheme is formally classified as type 1a certification scheme under ISO/IEC 17067 Conformity assessment – Fundamentals of product certification and guidelines for product certification schemes.

The TM66 Assured scheme examines each of the 66 questions of CEAM-Make and any accompanying evidence for all four tabs and compares them with CIBSE/LIA’s marking criteria. If the average comparative assessment mark across all questions for all four tabs exceeds 70%, the self-assessment will be deemed as passed and be eligible for certification.

Where the evidence provided indicates that the self-assessed score is significantly different to CIBSE/LIA’s marking criteria on one or more criteria then, providing that the average mark still exceeds 70%, a certificate will be awarded but only at the new CEAM rating, as calculated by CIBSE/LIA. The manufacturer can accept the revised CEAM rating for the product or appeal the decision. If a revised rating is accepted, the manufacturer has three months to show the revised score in all product and marketing literature or on any database or digital tool where the product is included.

As part of the assessment process, physical samples of the luminaire may require evaluation and testing to ensure that they are properly represented by the CEAM tool. Where an evaluation is unsuccessful, the manufacturer may be asked to provide additional evidence.

TM66 Assured allows for the assessment of family variants. Family variants are products that are essentially identical with respect to materials used, components, and technology applied, but may have minor differences, such as construction detail, or variation in specific materials. When evaluating family variants, the differences between the products are considered and the product that is considered most representative are selected for assessment.

Certifications are valid for a period of three years and, if requested by the manufacturer, the certificate may be reissued for a further three-year period following a review to determine whether the product still meets the requirements of the scheme. This takes account of updates to the supporting documents (for example, TM66 CEAM) or scheme requirements, as well as whether the product has undergone any changes in design or composition, or if there have been changes to the production location or facilities.

If no significant changes are identified, and the product is still in compliance with the requirements of the scheme, then the certificate will be reissued for a further three years. However, if significant changes are identified, then the certificate may be suspended or withdrawn. Minor changes leading to a change in CEAM rating will result in an amended certificate displaying that new rating, which will then be valid for a period of three years. Significant changes will require the assurance process to start afresh.

Before applying any changes to their TM66 Assured products during the certification period, the manufacturer has a duty to inform the assessor of any modifications that may affect certification. The impact of any changes will then be assessed and, where significant changes are identified, the manufacturer will be advised so that they can ensure that the product maintains its circularity credentials through its assured certification.

This formalised assessment can help manufacturers track their progress towards sustainability goals and make informed decisions about how to improve the sustainability of their products and processes. Production costs may even be reduced as a result of consequent improvements in the efficiency of their products and processes. The scheme can be used as a transition tool to help manufacturers plan and report on their transition to a circular economy. Consumers are increasingly demanding sustainable products,8 and certification can help manufacturers to differentiate their products from the competition, improve their brand reputation, and potentially attract new customers.

CEAM and similar tools provide an important step towards greater environmental sustainability and transparency in the lighting industry. The increased adoption of circular economy principles and standardised, assured metrics by manufacturers will help lighting designers, building operators, and owners to confidently select luminaires that are more sustainable.

Further details of the TM66 Assured programme are available at www.thelia.org.uk/page/TM66_Circularity

References:

- bit.ly/CJOct23CPD21 – accessed 6 September 2023.

- Grigoropoulos, CJ et al, An overview of environmental impacts of lighting products at the end of life stage through life cycle impact assessment, IOP Conf. Ser.: Earth Environ. Sci. 10.1088/1755-1315/899/1/012040.

- Dwyer, T, Towards a circular economy for luminaires, CIBSE Journal, October 2022.

- BS EN 15804:2012+A2:2019: Sustainability of construction works. Environmental product declarations. Core rules for the product category of construction products, British Standards Institution, 2019.

- Albu, H et al, Life cycle assessment of LED luminaire and impact on lighting installation – A case study, Alexandria Engineering Journal 80, 2023.

- bit.ly/CJOct23CPD22 – accessed 6 September 2023.

- bit.ly/CJOct23CPD23 – accessed 6 September 2023.

- bit.ly/CJOct23CPD24 – accessed 6 September 2023.