A recent International Energy Agency (IEA) report1 estimates heating in buildings is responsible for 10% of global emissions. The report highlights that the use of heat pumps, powered by low-emissions electricity, ‘are the central technology in the global transition to secure and sustainable heating’.

The refrigerants employed in heat pumps and associated heating and cooling technology applications in building services systems in the non-developing world are largely HFCs. HFC refrigerants are widely employed because of their good thermodynamic properties (with individual HFCs formulated to suit particular applications), and typically have limited flammability and low toxicity.

The evolution of HFCs was accelerated following the Montreal Protocol as a means of reducing ozone depletion. HFCs are referred to collectively, along with other fluorinated gases, as F-gases.

The release of F-gases into the atmosphere through leaks and discharges makes up around 2.4% of global greenhouse gas (GHG) emissions (according to 2019 data2). The HFCs used in heat pumps, refrigerators and other cooling devices are thought to account for more than 85% of global F-gas production. The F-gas regulation, originally introduced by the EU in 2014, has a key objective – to reduce the availability of HFCs in the marketplace, so encouraging applications of new and alternative refrigerants and novel technologies to reduce global atmospheric heating.

Desired outcomes of F-gas regulations

The phase down of refrigerants is only one aspect of the regulations. To reduce the mass of HFCs that could otherwise leak into the atmosphere, the F-gas regs have requirements that:

- Prevent F-gas release (intentional or unintentional)

- Minimise leaks and ensure timely repairs when detected

- Require regular leak checks and record-keeping and, in some cases, require leak detection systems

- Ensures recovery of F-gases for recycling, reclamation, or destruction when equipment is decommissioned or repaired

- Restrict the sale of equipment to businesses that do not hold relevant qualifications

- Ensure correct product and equipment labelling.

In the UK post-Brexit, UK-specific versions of the F-gas regulation came into force in January 2021, which technically mirror the EU F-gas regulation (EU No 517/2014). Compared with the baseline years (2009 to 2012), the current regulations have already reduced the official supply of HFCs by 55%, with a goal of 79% by 2030. Many manufacturers of split air conditioning units and heat pumps have worked swiftly to implement changes – notably with the widespread adoption of R32 (and blended refrigerants such as R454B) in high-pressure applications that formerly employed R410A.

There are numerous considerations to assess a potential refrigerant for operation at appropriate evaporating and condensing temperatures (as discussed in IoR Guidance Note 373) – not least the refrigerant density, operating pressures, thermodynamic properties and the resulting system energy performance, alongside safety in application, operation and reuse/disposal. Gluckman notes in his recent webinar4 that the swift changes in refrigerant application following the introduction of the F-gas regulation were built on many years of research and development, which began well before the regulation came into being.

The IEA report1 contends that even with today’s F-gas refrigerants and current rates of leakage, heat pumps still reduce greenhouse gas emissions by at least 20% compared with a high-efficiency gas boiler, even when running on emissions-intensive electricity. In regions accounting for 70% of world energy consumption, the resulting emissions savings are above 45%, and reach 80% in countries with cleaner electricity mixes. By employing alternative refrigerants, as discussed later in this article, IEA considers that these values can be improved by a further 10%.

The swiftly changing energy marketplace and the reinvigorated awareness of the impacts of climate change have accelerated the demand for the UK and the EU to undertake a review of the F-gas regulations. In April 2022, the EU set out a first set of proposals with an ambitious timetable of becoming EU law in 2023 (these will likely also influence the UK deliberations on legislation that is scheduled to come into force in 2024-25).

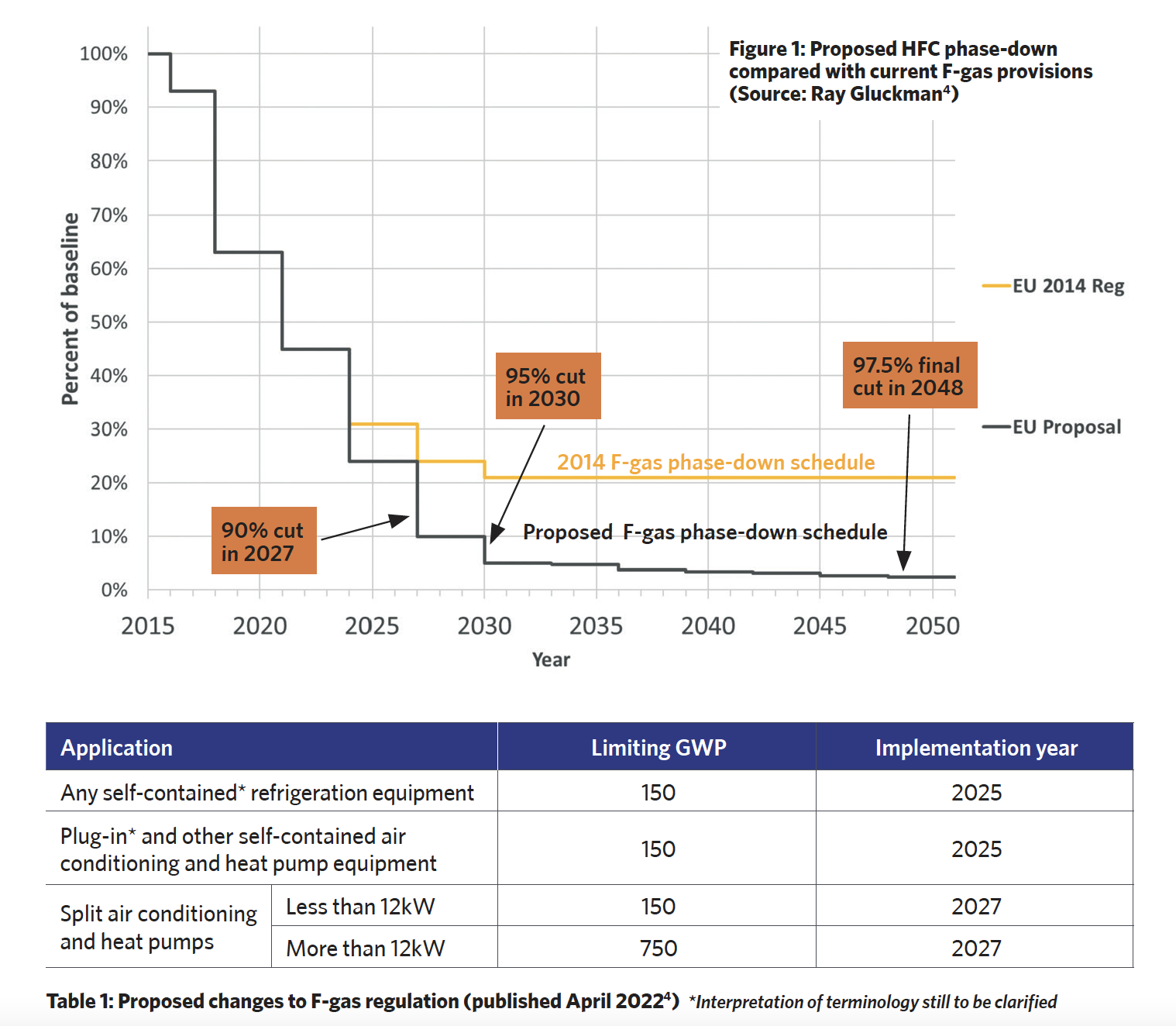

The proposals reinforce and extend the leakage, recharging, and refrigerant recovery provisions of the 2014 regulations but, most significantly, accelerate the phase-down schedule for HFCs to the timetable illustrated in Figure 1.

The headline proposals to accelerate the reduction in the availability of HFCs, as summarised in Table 1, have solicited both strong positive and negative opinions on the impact of a speedier reduction of HFCs.

To achieve GWP<150 in splits and heat pumps smaller than 12kW means potentially using a hydrocarbon (such as propane, R290); blended refrigerants such as R454C and R455A; pure HFOs such as HFO-1234yf or HFO-1234z; or a new, yet to be marketed refrigerant. As noted in the recent IEA report,1 switching to non-HFC refrigerants is technically possible, but there are risks impeding deployment, owing to the technical and cost implications, particularly as refrigerants cannot be simply swapped into existing units.

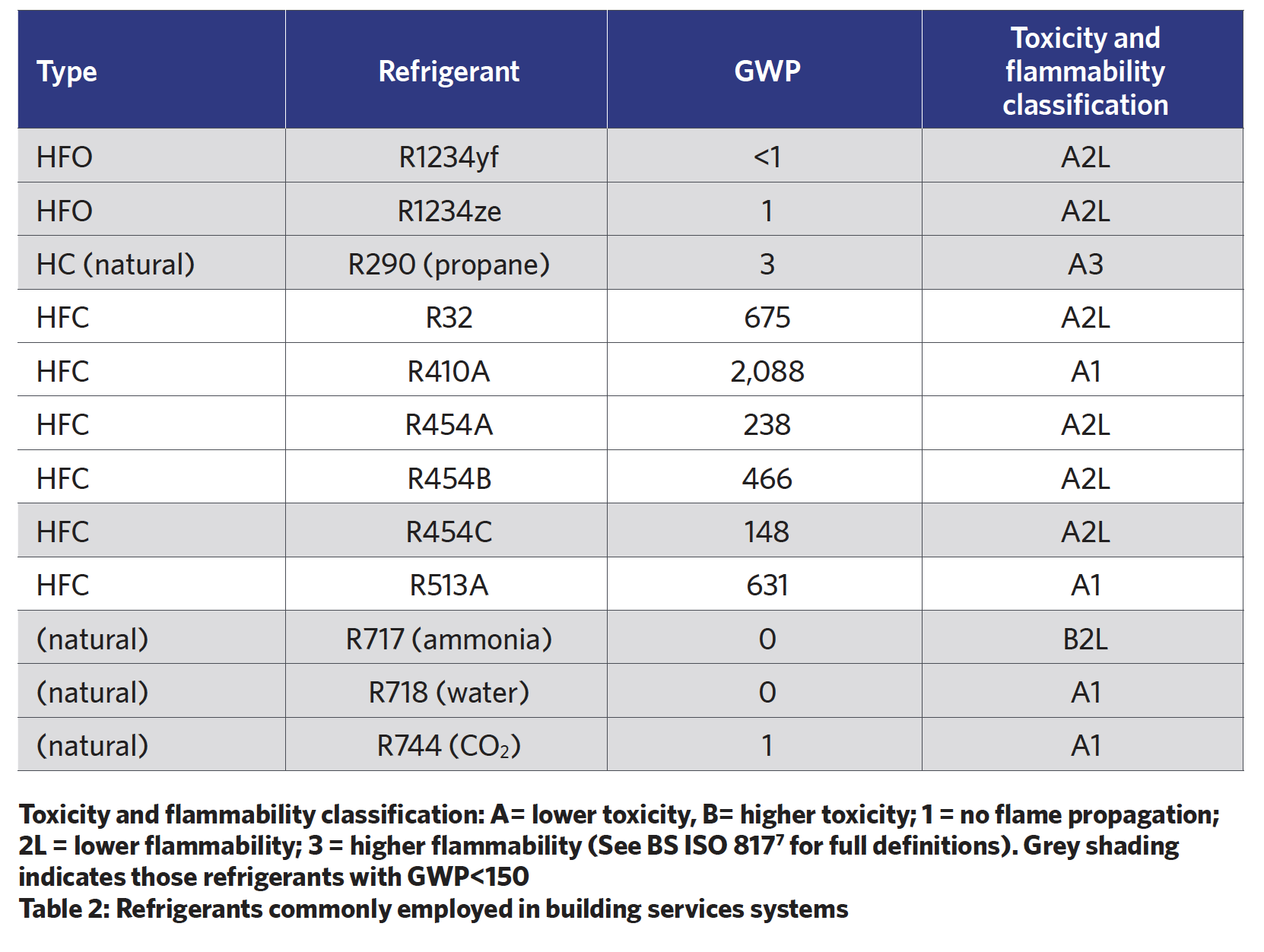

To meet the current – and future – F-gas requirements, some safety challenges will need to be overcome. As F-gas registration scheme operator REFCOM5 points out: ‘The downside to lowering the GWP of a gas tends to be the increasing flammability or related issues.’ All ‘flammable’ refrigerants (with flammability classification of 2L, 2 or 3 – see Table 2) will not ignite if the refrigerant concentration in room air stays below the lower flammability limit (LFL).

BS EN 378 Refrigerating systems and heat pumps – safety and environmental requirements sets limiting refrigeration concentrations that are deemed safe for applications in buildings. The standard relates the size of an occupied space with the amount of refrigerant (contained in pipework, fittings and components) allowed within that space, and also sets requirements for any leak detection devices.

Many of the replacements for the legacy HFCs are mildly flammable and are classified as 2L – they are hard to ignite, and have a slow burning velocity, are considered to be safe for use in approved systems, and can be considered safe for general handling with appropriate practices and, importantly, with properly skilled operatives.

BS EN 378 restricts the amount of A2L refrigerants that can be used in occupied spaces, as well as requiring leak detection systems, and this can make the application of the lower-GWP A2L refrigerants – for example, R32 – more complex in applications such as variable refrigerant flow (VRF) or split systems serving applications such as hotels and offices.

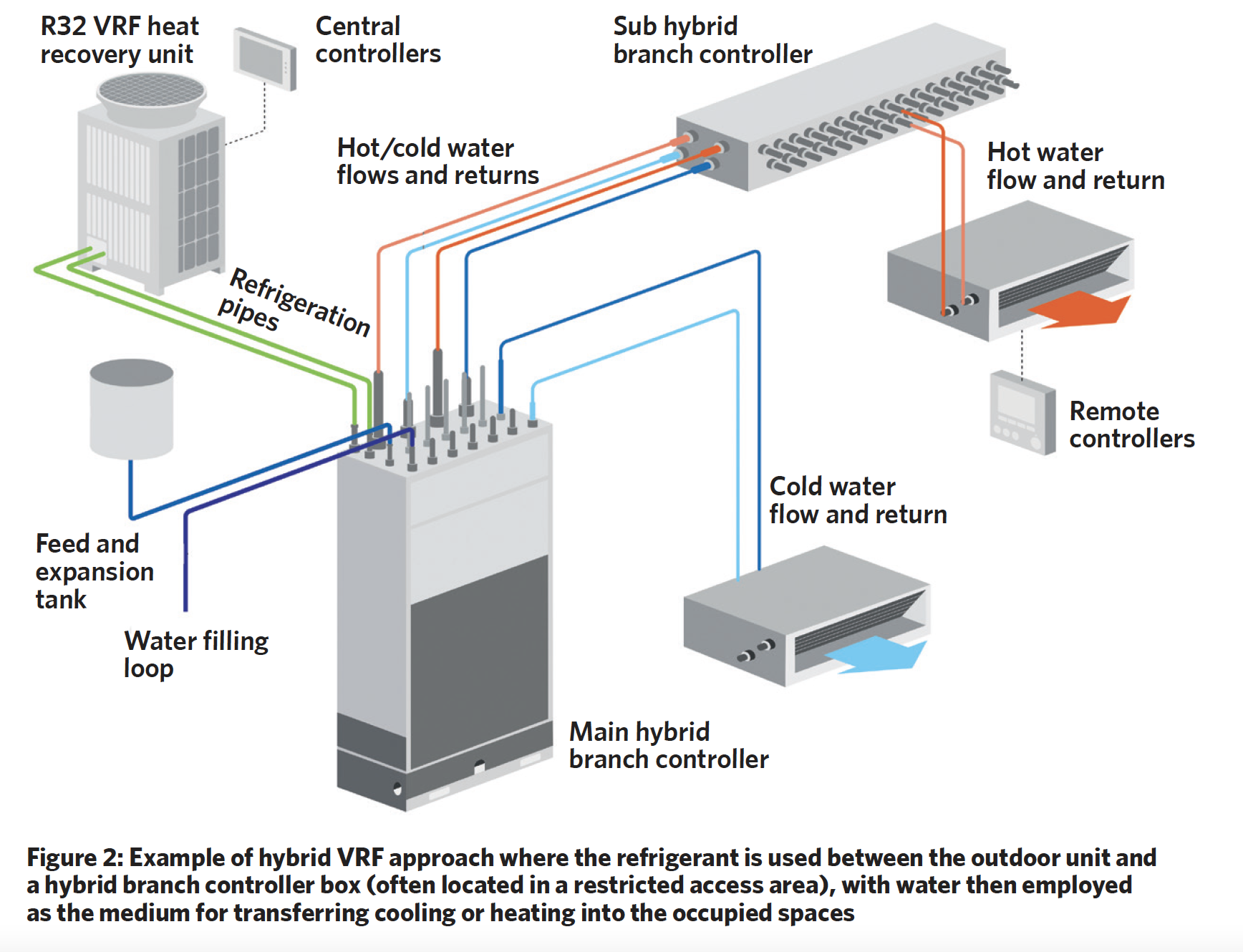

An increasingly common way to obviate the need for safety constraints (as standardised by BS EN 378) while providing effective controllable systems, is to utilise a hybrid VRF approach, where the refrigerant is used between the outdoor unit and a hybrid branch controller box (often located in a restricted access area), with water then being used as the medium for transferring cooling or heating into the occupied spaces, as illustrated in Figure 2. Not only does such a hybrid VRF remove the need for leak detection, but it also uses significantly less refrigerant than a traditional VRF system. As a result, the overall carbon footprint of the equipment is reduced, and ongoing maintenance costs (including replacement of refrigerant) are also reduced.

A review of the European standard EN 378 is currently under way. It is thought that changes will include new refrigerant charge limits that should allow a wider use of hydrocarbons, particularly in air conditioning equipment and heat pumps. Refrigerant charge will be more tailored to a given room size.6

CIBSE TM65 Embodied Carbon in building services a methodology specifically includes refrigerants as a significant contributor to the embodied carbon in building services systems. The refrigerant charge (the mass of refrigerant in the system) is related to the heating or cooling load and the method of distributing the heat around the building.

When using split systems, including VRF, the distribution length can be minimised, and hybrid solutions can be explored to reduce the mass of refrigerant in the system. TM65 provides some useful tables (in the appendix) of estimated ‘typical’ refrigerant leakage rates drawn from data collected from various global authorities – these are used in the assessment of the embodied carbon of a system.

To minimise leakage, TM65 notes some examples of good practice, including ensuring low leakage rates during the ‘use’ phase by frequent leak tests (as recommended by the F-gas requirements); good maintenance regimes to avoid constant overpressure (as overpressure can create small cracks in the coils); installing pipework with brazed connections rather than flare connections; using controls to detect potential leakage; and, critically, ensuring that refrigerant be totally recovered at the end of the product life following proper management procedures.

Table 2 provides a selected list of example refrigerants. Refrigerant R410A is specifically included, as it has been widely used in the industry for many years because of its stable performance as a refrigerant. However, its high GWP of 2,088 means that it is soon to be phased out and replaced with lower-GWP alternatives. R32 systems have already displaced many applications that would have formerly employed R410A. Hydrofluoroolefins (HFOs) and natural options such as propane, ammonia, carbon dioxide (CO2) and water offer very low GWP, as shown in Table 2.

Several chiller options have been developed that use low-GWP refrigerants, such as R32 or HFO 1234ze. Hydrocarbon (HC) refrigerants are increasingly applied for split systems and small heat pumps, particularly monobloc systems (which require a single outdoor unit). For VRF and larger split systems, A2L refrigerants seem to be a more likely option, with HFOs used for chillers and heat pumps. CO2 is already used as a refrigerant for hot water heat pumps such as the one illustrated in Figure 3.

The choice of refrigerant type will ultimately impact the energy performance, carbon emissions and embodied carbon of an air conditioning or heat pump system. The near future will see a variety of refrigerants developed and applied in the market, some that inevitably will produce unintended consequences.

However, there is no opportunity for status quo. With careful and holistic examination, innovative systems and applications will dominate as we strive for cost-effective, zero-carbon opportunities in delivering safe and comfortable built environments.

References:

1 The Future of Heat Pumps, IEA 2022.

2 IPCC Contribution of Working Group III to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change Section B.1.4 2022,

bit.ly/CJFeb23CPD1 – accessed 6 December 2022.

3 IoT Guidance Note 37 Guidance on Refrigerant Selection IoR 2021

4 Gluckman, R, Review of the EU Proposal for a Revised F-Gas Regulation, IoR, May 2022 –

5 TB/033: Working with lower flammability refrigerants, 2017 Federation of Environmental Trade Associations.

6 Latest news on regulations, F-gas regulations, IRR – accessed 6 December 2022.

7 BS ISO 817:2014+A2:2021 Refrigerants – Designation and safety classification, BSI 2021.