It was 35 years ago that the Montreal Protocol established a global phase-out schedule for the production and consumption of almost 100 ozone-depleting substances (ODS). An unintended consequence of the resulting worldwide action was the unexpected GWP of the replacements that were introduced to provide functional equivalency of the ODS that were being phased out. So, in 2016, the Kigali Amendment initiated the control of these fluorinated greenhouse gases (F-gases), calling for a global phase-down of more than 80% by 2050. In HVAC&R applications, these F-gases are principally HFCs. The EU (which, at the time, included the UK) adopted the F-gas Regulation EU 517/20141 and the mobile air-conditioning systems (MACs) Directive2 that essentially:

■ Limited the amount of HFCs that can be sold – planning to phase this in stages down towards one-fifth of 2014 sales by 2030

■ Minimised emissions of F-gases from existing equipment by requiring robust checks and efficient servicing, together with the recovery of gases at the end of product life

■ Prohibited use of F-gases where more environmentally friendly alternatives are available.

In January 2021, post-Brexit UK-specific versions of ODS and F-gas regulations came into effect, replacing the EU regulations. All the technical rules that were applied under the European legislation have been retained, but responsibility for reporting and management were amended to UK-specific authorities.

A Common Framework Agreement was established to ensure a unified approach across the four nations of the UK, although some of the reporting arrangements are different in Northern Ireland (as part of the EU single market) compared with those in Great Britain (England, Scotland and Wales).

Currently, the practical result is that the UK will continue to restrict ODS, in line with European legislation EC 1005/2009, and maintain the phase-down schedule for F-gas in line with EU 517/2014, reducing the placing on the market of F-gas by 79% by 2030 compared with the annual average demand during 2009-2012.

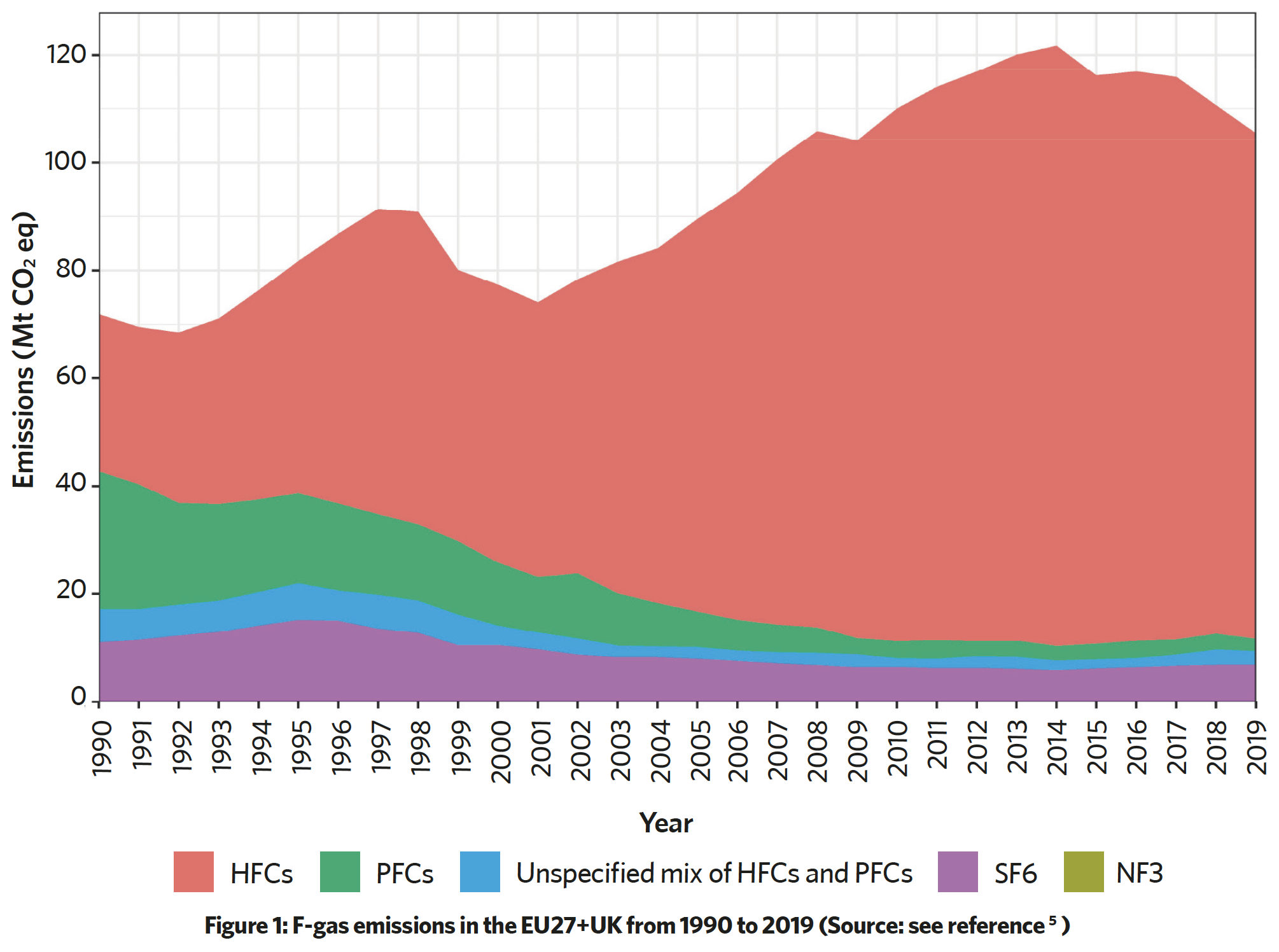

As described in a recent EU report,3 the supply of HFCs – in terms of their total CO2 equivalent impact, as illustrated in Figure 1 – has declined in Europe by 47% between 2015 and 2019.

In contrast, the supply of unsaturated HFCs, or hydrofluoroolefins (HFOs) – such as R1234yf (GWP = 4) as an alternative to R134a (GWP = 1,430); lower GWP HFCs, such as R32 (GWP = 675) as an alternative to R410A (GWP = 2,088) in split air conditioning, variable refrigerant flow (VRF), and heat pump applications; and R448A (GWP = 1,273), which is typically used to displace R404A (GWP = 3,922) in commercial refrigeration – has grown appreciably.

In the EU, refrigeration, air conditioning, heating and other heat transfer fluids account for the majority of F-gas use, estimated4 as 63% in 2019.

A significant share of the shift in warming impact of HFCs has resulted from the reduced use of key high-GWP HFCs and HFC blends – such as R134a, R404A and R410A – and while the amount of HFC contained in imported products and equipment has remained practically constant, the GWP of these HFCs dropped by 33% owing to increased application of lower-GWP HFCs.

In work5 undertaken for the EU, it is noted that there may be some undesirable environmental effects from the application of HFOs as a low-GWP alternative, related to the generation of environmentally persistent and accumulative trifluoroacetic acid (TFA) in the atmosphere, which will require further investigation.

There has also been a shift to natural alternatives such as CO2 (GWP = 1), propane (GWP = 3) and ammonia (GWP = 0) that are not restricted under the F-gas regulations.

As a result of the HFC phasedown, and the consequent restricted supply, prices for higher GWP HFCs have, by design, seen significant increases. In contrast, prices for alternatives that are not covered by the phasedown have largely remained more stable, making climate-friendly technologies more competitive. However, it was recently reported that HFCs still represent around 90% of F-gas emissions in Europe,6 contributing 2.5% of the EU’s total greenhouse gas emissions. (Internationally, F-gases are among the fastest growing greenhouse gases, largely as a result of increasing demand for refrigeration and air conditioning, especially in developing economies.).

The analysis5 undertaken on behalf of the EU indicates that the 2030 F-gas goals may not be fully reached under the current regulation. So, in April 2022, and coincident with the publication of the Intergovernmental Panel on Climate Change’s (IPCC) 6th assessment report,7 the European Commission (EC) made a proposal8 to transform the F-gas Regulation, upping the bar so as to reduce the amount of HFCs on the market by 98%9 by 2050 compared with 2015 (the target was previously 80%). Also, as of 1 January 2027, the proposal would ban split air conditioning and heat pump equipment with a capacity of more than 12kW that employs F-gas with a GWP of 750 or above.

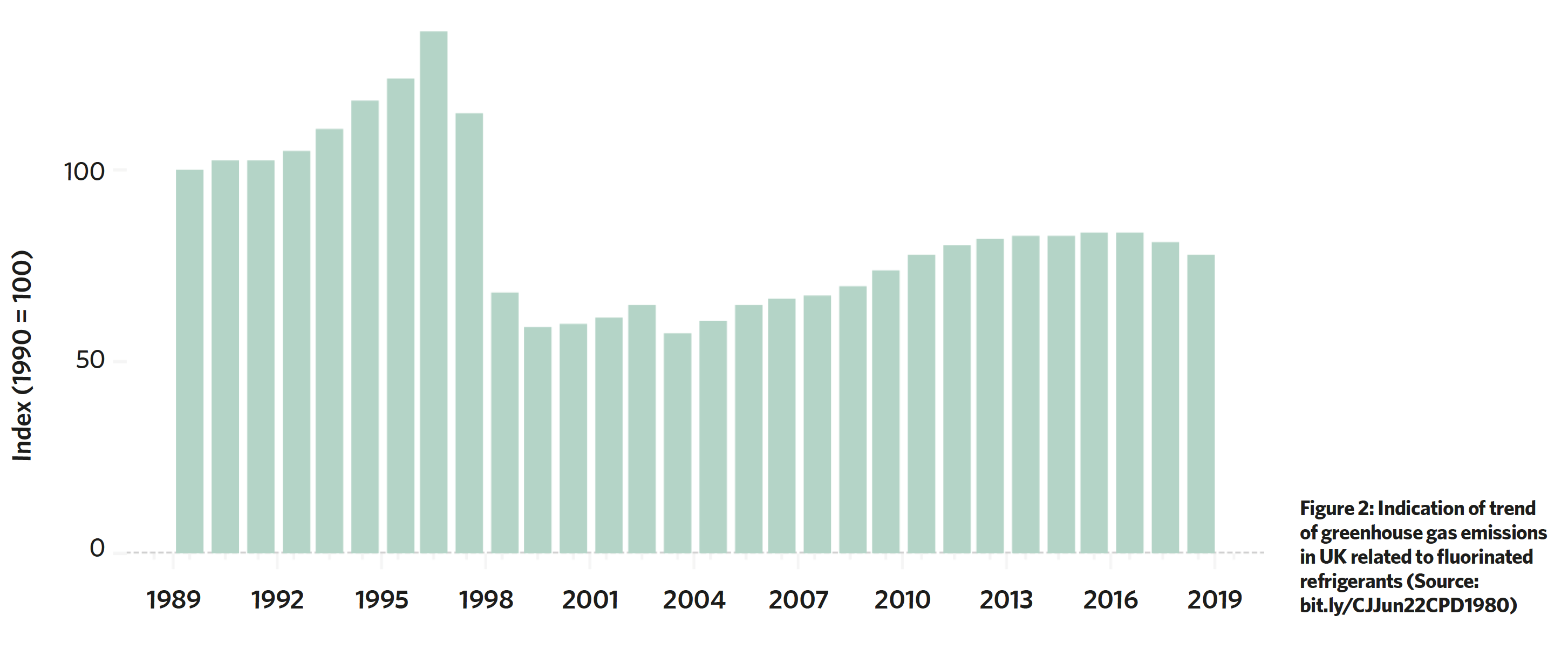

The new proposals have raised mixed concerns,10,11 in industry circles, with a key challenge – acknowledged by both the EC and the industry – being the skills shortage for the safe and effective installation of low-GWP refrigerants; the new EC proposals would require EU countries to expand their certification and training programmes. In the UK, the trend of GWP gas emissions resulting from fluorinated gases, as shown in Figure 2, has generally echoed that of EU emissions, as illustrated in Figure 1. There are suggestions that a revision of the UK F-gas regulations is in the pipeline, but neither the scope nor timetable is known.

Refrigerants are classified according to toxicity and flammability by BS ISO 817:2014+A2:2021.12 The toxicity of refrigerants is divided into two groups: class A (lower chronic toxicity) that have an occupational exposure limit of 400ppm or greater; and class B (higher chronic toxicity) that have an occupational exposure limit of less than 400ppm.

Refrigerants are also assigned to one of four classes (1, 2L, 2 or 3) based on lower flammability limit (the minimum percentage in the air that is tested as flammable), the maximum burning velocity, and the heat of combustion (class 1 being tested as no flame propagation through to class 3, higher flammability12).

The classification 2L was most recently added to better accommodate the increasing use of low-GWP HFCs and HFOs, as otherwise they were simply categorised as class 2 (now known as ‘flammable’) – as 2L, they are designated ‘lower flammability’. As reported in last month’s CIBSE Journal,13 recent tests have reinforced the understanding that A2L refrigerants are difficult to ignite, have slow flame speed and low heat of combustion, and can be safely applied with proper designs and installations.

R32, designated as an A2L refrigerant, is a well-established refrigerant with a lower GWP (of 675), zero ozone depletion potential (ODP), and lower flammability. It was initially mainly used in blended refrigerants, notably in equal parts with fire suppressant R125 to form R410A. Around 10 years ago, small R32 compressors were developed for the Japanese market and their use has subsequently spread globally, particularly in applications that would have previously used R410A. R32 has operating characteristics that are similar to R410A, but it requires a lower refrigerant charge and can provide significant efficiency gains.14

As a single component fluid, with a single carbon molecule, there are no ‘glide’ or ‘fractionation’ issues that exist with blended (zeotropic) gases and, as a single component refrigerant, it has a single pressure-temperature relationship that eases the understanding of performance in the field, and is more straightforward to recycle than blended refrigerants. Current R32 compressor designs have been introduced that very closely match the design and footprint of R410A compressors. (R32 is not suitable as a drop-in replacement for R410A and must only be used in systems specifically designed for R32.)

In the UK, all classes of refrigerant are within the scope of the 2002 Dangerous Substances and Explosive Atmospheres Regulations (DSEAR), and so all refrigeration, air conditioning and heat pump (RACHP) installations must be compliant.15 As noted by REFCOM/BESA Technical Bulletin 3316 for a new installation, there needs to be a risk assessment carried out that reviews the application, refrigerant charge, location of components, and occupancy of any room containing refrigerant holding components.

Figure 3: An example of an inverter-controlled external unit supplying VRF (VRV) internal units with integrated refrigerant safety measures and heat recovery, employing R32. This range delivers up to 90kW heating capacity (@indoor 20°C DB, outdoor 7°C DB, 6°C WB) and 80kW cooling (@indoor 27°C DB/19°C WB, outdoor 35°C DB) with standardised SEER 7.1, SCOP 4.1 (Source: Daikin21)“]

BS EN 378:2016: Refrigerating Systems and heat pumps – Safety and environmental requirements contains design information for the risk assessment and management process, and is a key publication when at the planning stage of an A2L installation. The standard is used for calculating the maximum permissible refrigerant charge in a system, based on both toxicity and flammability. However, BS EN 378:2016 notes that ‘where product standards exist for particular types of systems and where these product standards refer to refrigerant quantities limits, such quantities shall overrule the requirements of this standard’.

The most recent revision of BS IEC 60335-2-40:2018,17 a product standard, was developed to safely accommodate the application of the lower-flammability refrigerants in heat pumps, air conditioners and dehumidifiers, and is currently scheduled for publication by BSI18 in July 2022. This standard will work together with BS EN 378:2016 to provide contextual flammability guidance for the application of products, including heat pumps and air conditioners.

As noted in the recently published BSRIA TG 21/202219 ‘mitigating measures, as set out in BS EN 378:2016 may include fixed refrigerant leak detection, audible and visual alarms and forced ventilation to dilute any refrigerant build up.

A combination of these mitigating measures will often allow for a much greater refrigerant charge to be applied than without them’. The methods that can be implemented depend on the smallest room area and total system charge, and any measures must be triggered by a leak detection system, unless there is permanent and adequate natural ventilation or continuous and suitable mechanical ventilation.

As the regulations evolve to accommodate the safe application of A2L refrigerants, manufacturers are producing solutions that simplify the rollout of new systems that employ these lower-GWP refrigerants. For example, the system shown in Figure 3 integrates technology to overcome the technical barriers to applications of A2L refrigerants, at both the design and operational stages, to provide safe and legal deployment.

The system20 is supplied with factory-fitted components and integrated controls to meet safety requirements, ease the installation process, and ensure compliance. This includes self-monitoring, with integrated sensors to detect refrigerant leaks in indoor units, which automatically activates visual and audible alarms as well as selectively isolating the refrigerant line serving the affected area.

The applications of lower-GWP refrigerants in HVAC&R are, by necessity, increasing swiftly. This is ushering in new technologies that require new skills and a solid understanding of the benefits and risks and, as with all building services applications, demand a holistic appreciation of the wider impacts of system installation and operation. Advice and regulation are racing to keep up and are likely to change rapidly, so designers and operators need to maintain a close watch on developments.

© Tim Dwyer, 2022.

References:

1 Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation (EC) No 842/2006.

2 Directive 2006/40/EC of the European Parliament and of the Council of 17 May 2006 relating to emissions from air conditioning systems in motor vehicles and amending Council Directive 70/156/.

3 Evaluation and impact assessment for amending Regulation (EU) No 517/2014 on fluorinated greenhouse gases Briefing paper for the stakeholder workshop: Preliminary findings, 6 May 2021.

4 EEA Report No 15/2020 – Fluorinated greenhouse gases 2020 – Data reported by companies on the production, import, export and destruction of fluorinated greenhouse gases in the European Union, 2007-2019, European Environment Agency 2020.

5 Birchby, D et al, Support contract for an Evaluation and Impact assessment for amending Regulation (EU) No 517/2014 on fluorinated greenhouse gases – CLIMA.A2/ETU/2019/0016 Evaluation Final Report, March 2022.

6 Questions and Answers: New rules proposed on fluorinated greenhouse gases and ozone depleting substances, European Commission – accessed 5 May 2022.

7 IPCC Sixth Assessment Report – accessed 4 May 2022.

8 Proposal for a regulation of the European parliament and of the Council on fluorinated greenhouse gases, amending Directive (EU) 2019/1937 and repealing Regulation (EU) No 517/2014, EC 2022.

9 Green Deal: Phasing down fluorinated greenhouse gases and ozone depleting substances, April 2022

– accessed 4 May 2022.

10 Proposed new F-gas Regulation: EU risks undermining its own climate and energy security goals, AREA, EPHA, EPEE, April 2022 – accessed 4 May 2022.

11 EU Releases Proposed F-Gas Regulation, Opening Doors for Ammonia, Ammonia 21, April 2022

– accessed 4 May 2022.

12 BS ISO 817:2014+A2:2021 Refrigerants. Designation and safety classification, BSI 2021.

13 Viva Las Vegas, CIBSE Journal, May 2022,

14 Konghuayrob, S and Khositkullaporn, K, Performance Comparison of R32, R410A and R290 Refrigerant in Inverter Heat Pumps Application, The International Refrigeration and Air Conditioning Conference, 2016.

15 Guidance on Risk Assessments for compliance with Dangerous Substances and Explosive Atmospheres Regulations (DSEAR), FETA 2019.

16 Technical Bulletin TB/033: Working with lower flammability refrigerants, REFCOM/BESA 2017.

17 BS IEC IEC 60335-2-40:2018 Household and similar electrical appliances – Safety – Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers, BSI 2022 (to be published 13 July 2022).

18 BS IEC IEC 60335-2-40:2018 Household and similar electrical appliances – Safety. – Part 2-40: Particular requirements for electrical heat pumps, air-conditioners and dehumidifiers, bsi – accessed 5 May 2022.

19 Fox, G, TG 21/2022 Refrigerants in Building Services, BSRIA/BESA 2022.

20 Daikin VRV5 heat recovery, – accessed 11 May 2022.

21 Meet our superhero: VRV 5 Heat Recovery, Daikin – accessed 11 May 2022.