There is significant national and international legislation aimed at decarbonising the UK heat supply, and planning regulations often require new developments to include a proportion of renewable technology in order to reduce carbon emissions. An initiative by CIBSE, the Heat Pump Association and the Ground Source Heat Pump Association created CP2, the code of practice for surface water source heat pumps to provide a framework guiding the proper deployment of SWSHPs.

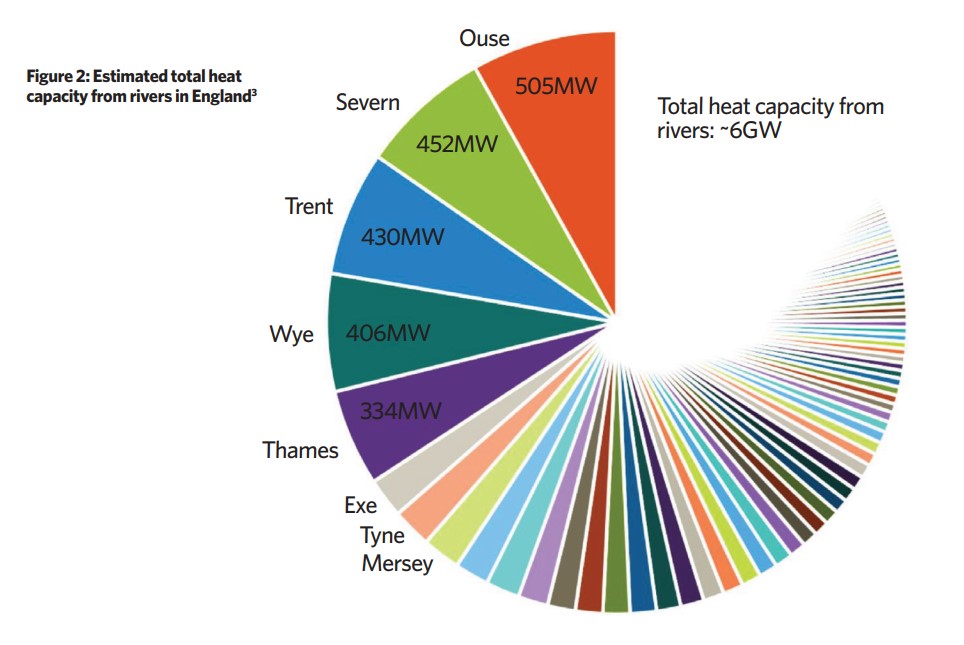

This was aimed at increasing the opportunity of good quality applications of this well-proven technology to help meet the heat demand with reduced environmental impact. A measure of the potential for the deployment of surface water source heat pumps was detailed in research undertaken by Atkins1 (originally as part of the now-decommissioned UK National Heat Map project). This estimated the total heat accessible capacity from rivers alone at approximately 6GW in England, as illustrated in Figure 2, which equates to direct electrical heating by the equivalent of six Hinkley B nuclear power stations.

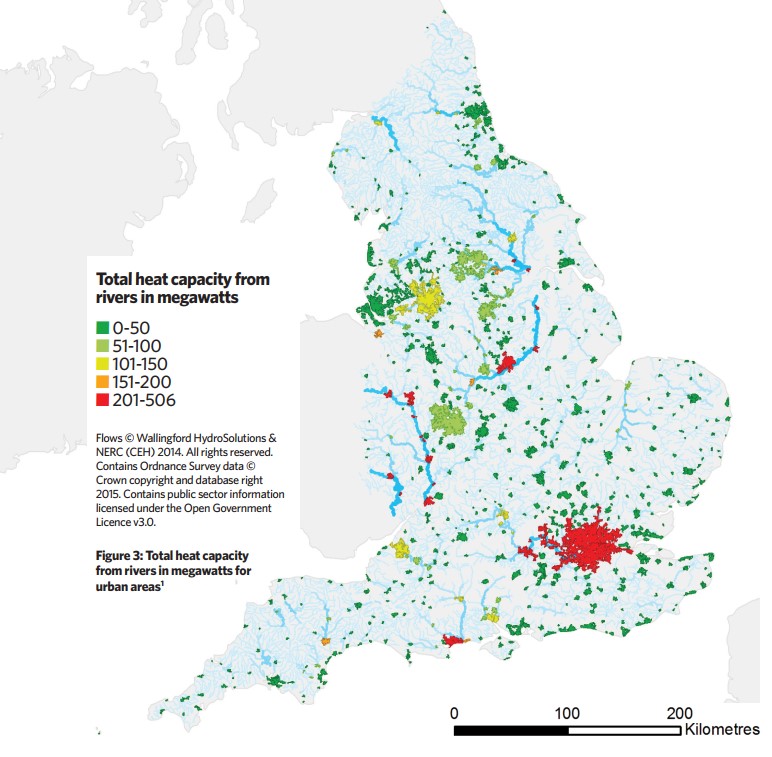

The water source heat map document not only analyses the potential of water heat sources in England (as in the example map shown in Figure 3), but also includes an extensive commentary on the methodology to assess the feasibility of water sources.

As part of Monitoring of Non-Domestic Renewable Heat Incentive Ground-Source & Water-Source Heat Pumps,3 produced for the UK government, the performance of several non-domestic water source heat pumps was monitored over at least one heating season. Since it was for a limited period and for relatively few installations (that were chosen from those registered for the non-domestic RHI4), the authors of the report are clear that the observed performance of this sample should not be taken as representative of the whole marketplace. However, their work identified aspects that impact all installations, a few of which are described here.

As with the application of any heat pump (such as the 42kWth unit shown in Figure 4), the report notes that the main influence on heat pump performance is the difference between the temperature of the cold source as input to the heat pump and the temperature of the hot output – known as the ‘temperature lift’. And this proved to be the case in the monitored systems, as those with low temperature lift tended to have higher performance.

Two of the systems monitored used source water pumped directly to the heat pump evaporator, with no intermediate heat exchanger, and one of these was the one with the highest performance of all monitored systems. The report does, however, identify the challenges of using direct source water, including fouling and freezing in the evaporator. This report – and particularly the associated case studies – provides an extremely well-illustrated reference to the operational performance of the systems, and has some useful system schematics.

It concludes that ‘numerous factors influence heat pump performance. There is not one overriding factor that needs to be addressed, but more careful design, installation, commissioning and operation are all required to ensure a high-performance system’.

CP2 Surface water source heat pumps: code of practice for the UK5 aims to raise standards across the supply chain and so stimulate adoption of the technology. It encompasses all stages of the development cycle – from preparation and briefing through to planning for the eventual end-of-life decommissioning of systems. CP2 is written so that it can be included in the tendering/contracting process to specify minimum requirements for a project.

It contends that it ‘is not necessary to be a technical expert in SWSHP systems to use the code for procurement or contractual purposes as it has been designed to give clients and developers confidence that commonly agreed minimum standards are being followed, and to allow clear communication between different parties in the supply chain’.

CP2 covers the process for assessment and development of both open-loop and closed-loop surface water source heat pumps. However, it is not intended to provide technical design detail, but to set minimum requirements for the technical application of SWSHPs. (It also includes a useful technical primer and some relevant case studies.)

The CP2 framework provides a route to a more integrated design, with key principles properly considered and implemented from the initial brief and feasibility through to operation, ensuring that operational costs are fully accounted for in the design/development stages and that the system is correctly commissioned prior to the operational phase. The overarching aim of the code is to ensure the SWSHP system works effectively, is reliable, cost-effective and does not harm the environment.

It emphasises that systems should be specified to have a long life and require little maintenance – in particular, the source side needs careful consideration to ensure filtration systems work with minimum human intervention. There is significant detail in the code, broken into six requirements: preparation and briefing; feasibility; design; construction and installation; commissioning; operation and maintenance; and decommissioning.

At the earliest stages in the project, the owner/developer will need to ensure that the project is likely to comply with relevant legislation and any conditions imposed by other stakeholder organisations – for example, the local planning authority and the relevant environmental agency.

The project brief is used to define the steps required to assess the viability, focus project planning activity, assess the marketplace, and identify suitable specialists required to deliver the project. At the feasibility stage, assessments should be made of the environmental impacts and the primary energy demand of a system throughout its life cycle – these will be further developed as the design progresses. The characteristics of the water source will inform the practicality of using a SWSHP, as well as the choice between open- and closed-loop systems.

Accurate estimates of both the peak output requirement and annual heating and cooling demand, together with the consumption profile and desired operating temperatures, are important. For existing non-domestic buildings, the current building operator will need to work with the design team to define the peak heat demand and required temperatures.

In new buildings, where modelling will be needed, it will differ significantly from the modelling required to show compliance with local Building Regulations. (CIBSE TM54 Evaluating operational energy performance of buildings at the design stage6 provides a method for making accurate energy assessments.)

The type and number of heat pumps in the system and the associated elements – such as thermal storage, isolating heat exchangers and dry air coolers – need to be assessed, as well as the financial and operational advantages of using a multivalent system.

The size and selection of components will resolve as the design matures. The location of the heat pump and the positioning and design of abstraction and discharge ports, or submerged closed loop heat exchangers, are critical decisions that will involve accounting for factors such as existing building systems/services, flood risk, access, cost, noise and security considerations.

At the feasibility stage, financial analysis will be required to model the costs and benefits of the various options. Capital cost, operating cost (including income from grants and incentives and from any heat sold), whole life cost (including disposal costs), and internal rate of return on the investment need to be investigated to inform and drive design decisions.

The range of required, and timely, permissions will vary from site to site, and any oversight can cause costly delay and disruption.

A risk register should be developed from the outset, and this should be reviewed and updated throughout the project, with sensitivity analysis applied to quantify the impact of the identified risks.

Financial projections, which benefit from life-cycle cost analysis, are used in conjunction with the risk register to evaluate the effect of uncertainty in a range of appropriate parameters or objectives, and the costs and benefits of mitigating the risk. (CIBSE Guide M7 provides information for life-cycle analysis of components.)

Having completed a risk assessment, the designer must mitigate these risks by making appropriate design decisions, and assess how the proposed design will be constructed, operated and maintained. The business model should be regularly updated throughout the stages of the project so that, as the design develops, the targets can be checked and adjustments made so that the overall cost of the project is managed within the budget.

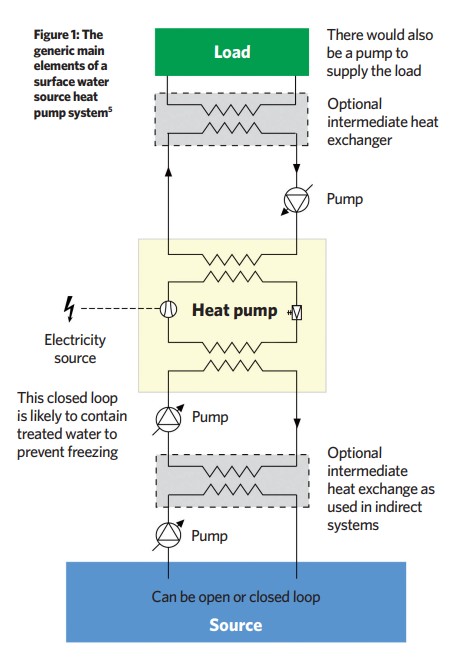

Source-side maintenance is particularly important to ensure reliability and provide optimum performance, and the design must take account of the water quality and any other factors that could degrade performance. An important design choice is whether the heating and/or cooling load are directly or indirectly connected to the heat pump through an intermediate heat exchanger, as shown in Figure 1.

Figure 4: Example 42kWth heat pump, COP of 4.9 (0°C source/35°C load), as used for indirect surface water source applications, such as closed loop systems providing heat for underfloor heating (Source: Hoval)

Indirect connection means that the heat pump and building distribution fluids are kept separate, and this is likely to simplify heat metering. Direct connection is less complex, having fewer components, so potentially lower maintenance is required, and there are fewer potential points of failure – although implications of passing source water directly through the heat pump’s heat exchangers need careful consideration.

There is no loss of temperature and efficiency between primary and secondary circuits across a heat exchanger, and less plantroom space is needed.

For an efficient system with a low whole-life cost and long life, appropriate standards of insulation should be applied – grants and incentive schemes may have requirements that consider heat loss in pipework. Instrumentation such as flow, temperature and pressure sensors, and associated monitoring hardware and software, is needed to monitor and record the performance of the installation for display, diagnostic and reporting purposes.

The requirements of CP2 continue beyond the design phase, right through to eventual decommissioning needs. However, as with this article, information may be used selectively for a particular stage or stages – although ‘the greatest value will be gained when it is followed for all stages of the project’.

Although CP2 may appear to make the deployment of SWSHP complex, many similar tasks and objectives would be required for other traditional and other renewable heating and cooling technologies. Following the requirements of this code of practice will ensure that legislative and regulatory requirements have been met, and that the information produced will allow effective oversight of the project. But, above all, the resulting system has the best chance of providing users increased financial benefit while exploiting renewable energy sources with properly considered environmental impact.

Ensuring Renewable Heat Incentive benefit

There are a number of requirements for an installation to benefit from the Renewable Heat Incentive (RHI) for electrically driven water source heat pumps. These include that the heat pump should have a coefficient of performance (COP) of at least 2.9 and a design seasonal performance factor (SPF) of at least 2.5 (based on heating and not cooling). For smaller installations (<45kWth), despite not being ‘domestic’ systems, the installations must have Microgeneration Certification Scheme (MCS) certification or equivalent – this is also required if any of individual heat pumps have a thermal output of less than 45kWth when several heat pumps USE a shared source loop.

Further reading:

This article draws on the text of the CP2. However, there is much greater detail, and range of information in the original document.

CIBSE TM51 Ground source heat pumps provides detailed information on the associated heat pump technology and its life-cycle assessment.

The Heat Pump Association recently published Delivering Net Zero: A roadmap for the role of heat pumps that highlights policies that the industry regard as needed to support increased deployment of heat pumps in the UK – see

www.heatpumps.org.uk/resources/

The Ground Source Heat Pump Association’s website has a wealth of technical information – see www.gshp.org.uk/

References:

1 National Heat Map: Water source heat map layer DECC, 2015 – bit.ly/2SRruLf – accessed 31 December 2019.

2 Non-Domestic Renewable Heat Incentive: Guidance Volume 1: Eligibility and how to apply, bit.ly/CJFeb20Ofgem – accessed 31 December 2019.

3 Hughes, D, The Monitoring of Non-Domestic Renewable Heat Incentive Ground-Source & Water-Source Heat Pumps Final Report Prepared by GRAHAM Energy Management, BEIS February 2018 – – accessed 31 December 2019.

4 Non-Domestic Renewable Heat Incentive (RHI) website, Ofgem – accessed 31 December 2019.

5 CP2: Surface water source heat pumps: Code of Practice for the UK. Harnessing energy from the sea, rivers, canals and lakes, CIBSE, HPA, GSHPA 2016.

6 TM54 Evaluating operational energy performance of buildings at the design stage’ CIBSE 2013.

7 CIBSE Guide M: Maintenance Engineering & Management, CIBSE 2014.

© Tim Dwyer, 2020.

- With thanks to the many contributors who created the source material for

much of this article – CP2 Code of Practice for the UK Harnessing energy from the sea, rivers, canals and lakes.