There is a continuing and increasing interest from building designers, occupants, owners and operators in maintaining internal environments that provide good levels of air quality. The motivation to deliver building systems that positively contribute to the health, wellbeing and productivity of occupants has been heightened by reports from respected institutions and the media of the deleterious impacts of climate change and poor external air quality.

This article will review the current challenges in maintaining appropriate internal air quality and consider the application of augmented mechanical ventilation with heat recovery (MVHR) – which may gradually become more prevalent in homes and small commercial applications in traditionally temperate climates that have formerly eschewed mechanical cooling.

The recently published report The inside story: health effects of indoor air quality on children and young people1 drew on many contemporaneous studies, one of which2 indicates that, from a sample of 1,060 people in the UK, the average person is likely to spend 22 hours a day inside.

One of the report’s conclusions is that there is evidence of many UK homes without adequate ventilation – and although the health effects of many of the products and materials used in buildings have not been comprehensively studied, there are indications that they could result in harmful health effects.

Ventilation is required in buildings to provide outdoor air for the occupants – who typically inhale less than 0.25 litres per second3 – but mostly to dilute and extract odours, water vapour and other airborne pollutants. The above-mentioned report provides an excellent summary of contaminants that affect indoor air quality (IAQ), and the box out on page 58 points to a downloadable sheet to explore the impact of ventilation rates on indoor contaminant levels.

However, there is also a need to ensure that, by actively ventilating a space with potentially contaminated outdoor air, it does not increase the problems with IAQ – particularly because, as reported by the Lancet Commission on pollution and health,4 ‘pollution is the largest environmental cause of disease and premature death in the world today’.

Exploring the impact of ventilation on indoor contaminant levels

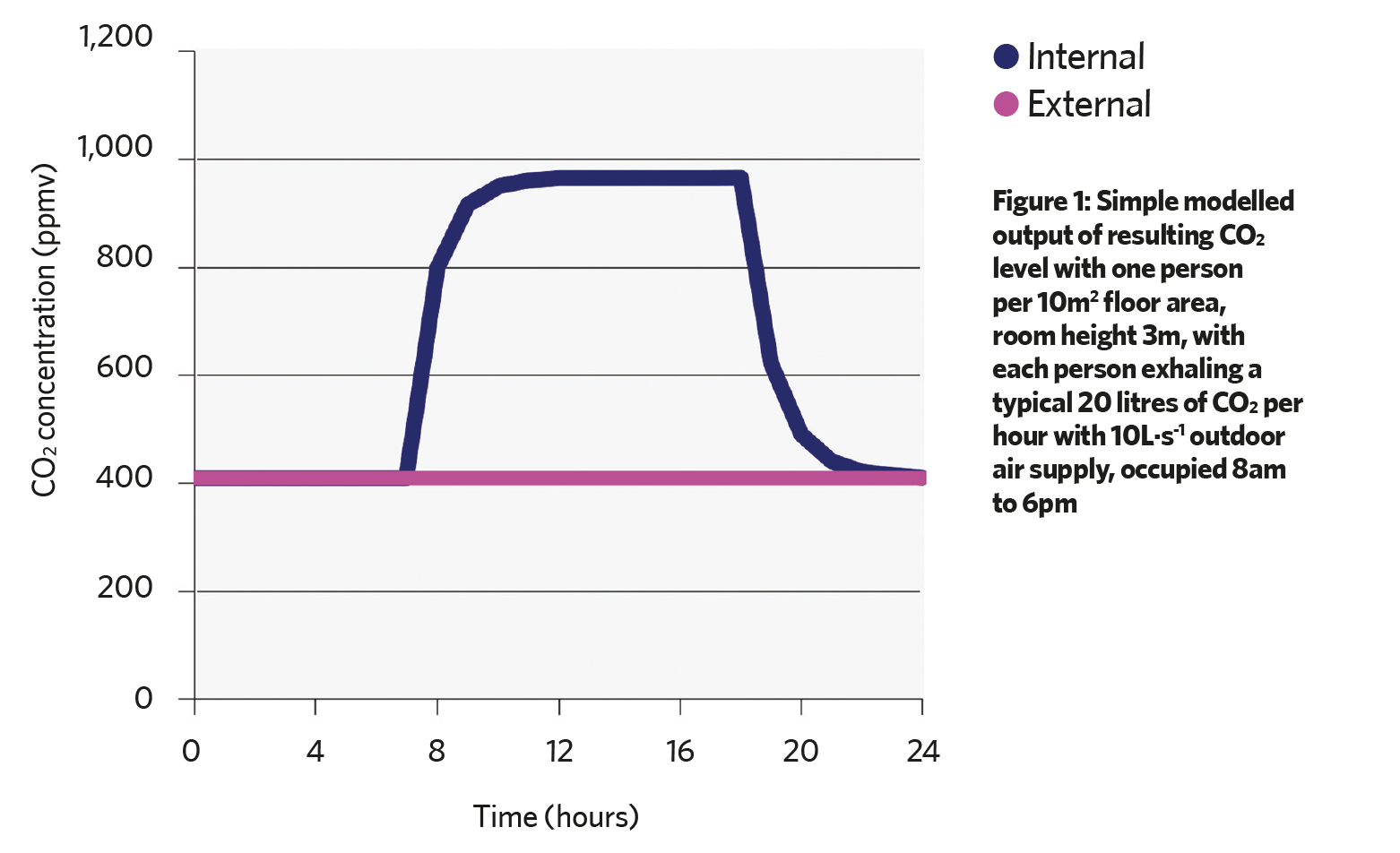

A key marker (or ‘proxy’) that has been used to infer the quality of indoor air in occupied spaces has been the concentration of CO2 in the indoor air, with the assumption that if there is sufficient ‘fresh’ (outdoor) air to adequately dilute the CO2 emitted through human respiration, there will be an acceptable IAQ. The IAQ sheet on the freely downloadable CIBSE spreadsheet provides a useful tool to undertake CO2 analysis for a single zone.

So, for example, Figure 1 illustrates that a space occupied from 8am to 6pm with an outdoor air supply rate of 10L·s–1 per person will lead to an increase in CO2 of 555ppm (assuming approximately one person per 10m2 floor area exhaling 20 litres CO2 per hour per person).

As outdoor CO2 is approximately 410ppm, this would create an indoor CO2 level of less than 1,000ppm – a level that is commonly set as a reasonable limit value.

CO2, however, is just one of the many pollutants in indoor air and is related to occupancy. Other contaminants, such as volatile organic compounds (VOCs) and particulates, will not necessarily have any relationship with occupancy, but models – such as the CIBSE spreadsheet – can be readily adapted to explore the impact of ventilation on the concentrations of other pollutants.

Ventilation has traditionally been provided in homes and small commercial applications through natural means such as windows, chimney stacks for open fires, and the fortuitous infiltration of outdoor air through cracks and openings in the structure. In more recent years, the mandatory use of trickle vents has attempted to replace these former routes of entry for outdoor air but, although simple, they provide no practical control and may become obstructed in use.

In common with CIBSE (and other principal authorities) the recent National Institute for Health and Care Excellence (NICE) guidance5 indicates that the best solution is to design out the source of pollutant, and notes that a whole-building approach should be adopted for heating and ventilation.

This includes balancing IAQ with standards for energy use, using heating systems that minimise exposure to particulate matter, and ensuring there is permanent, effective ventilation.

There are many ventilation methods that, when designed and implemented appropriately, produce increased rates of ventilation, as well as enabling more selective and controlled ventilation. More than half of new-build homes (based on ATTMA dataset 2015-16 data reported by Crawley6) are naturally ventilated.

However, increasingly challenging conditions – particularly related to overheating and air quality – are encouraging designers to evaluate the need for alternative systems. Any ventilation arrangement that does not incorporate heat recovery will have an indirect operating cost for heating the ventilation air (by the building’s heating systems) when it is drawn into the building.

The supporting document for the England Building Regulations Approved Document F (ADF7), Domestic Ventilation Compliance Guide,8 has extensive requirements that also provide a useful basis for best-practice installation and commissioning of the various systems.

ADF categorises and illustrates ventilation in terms of four generic systems. It is currently under review as part of the development of a UK Future Homes Standard, and a new version is expected later in 2020 that is likely to require performance-based evidence that there is adequate means of ventilation for building occupants.

Where there is an opportunity to include a riser ‘stack’ duct through the building, passive stack ventilation may be used (ADF System 2 – <1% of installed systems in new homes dataset6). This employs a combination of natural stack effect, together with the venturi effect, to draw air from inlet grilles mounted at ceiling level in selected rooms (for example, shower room, kitchen or utility room).

This requires no power, is practically silent, and has no direct cost of operation, but the airflow rate will be dependent on the outdoor temperature and wind velocity. Automatic or manually actuated dampers (mounted in the stack) may be used to vary the flow.

Airflow may reverse in summer or at times of high winds, which can cause smuts to be carried into the room from the (inevitably) contaminated ducting. These systems will provide limited summer ventilation – this may be augmented by opening windows as appropriate.

As with all natural and extract-driven ventilation systems, trickle vents – or, possibly multiple, other purpose-made unfiltered openings – will be required to allow the flow of the make-up outdoor air.

Intermittently actuated extract fans – through walls and windows, and with ducted discharges – may be used where there is a specific generation of contaminant, such as in a kitchen or wet room, and the make-up, unfiltered ventilating air is drawn through openings, including trickle vents and fortuitous leakage around doors, windows and gaps in the building fabric (ADF System 1). Using manual or automatic control, this method may be applied as a means of purge or task ventilation, or could be used continuously.

Such a simple system may be readily retrofitted, and can be very cheap to install and operate. Although simple in form and operation, however, it may not be operated by the building occupant as intended – for example, because of problems with noise or a lack of understanding – so it may not be an assured method of maintaining good IAQ.

Providing multiple building penetrations to accommodate the outlets may be challenging, particularly in multi-storey buildings. Fans may be added to passive stack ventilation ducts (discussed above) to provide a hybrid system for use when there is more ventilation required than is given by natural means only. These can be controlled automatically – for example, through humidity sensors or selective IAQ sensors – or manually.

To remove the uncertainty of natural ventilation and improve controllability, automatically controlled continuous extract systems may be employed (ADF System 3). These are normally ducted systems with a centralised fan unit, typically linked with radial ductwork of 100mm-diameter flexible or rigid plastic rectangular ducts to ceiling grilles mounted in areas requiring extract ventilation.

Alternatively, decentralised mechanical extract ventilation (dMEV) is used, which consists of continuously running extract fans. Low-power fans are typically located in every wet room, running continuously at low trickle speeds, which are then boosted as required via automatic or manual control. As the power to move the air is supplied by the fan, any ductwork is able to take a more circuitous route (with the associated increased resistance to flow and additional fan power), and the openings to draw in outdoor air may be smaller or fewer.

This system is relatively simple to satisfy demand through automatic or manual control (to vary flowrates to allow purging). There will be an operational cost for fan power in addition to the heating load, to account for the ventilation air in winter.

As the systems are relatively independent of outdoor conditions, they can provide year-round ventilation, and where there is opportunity to open windows – particularly in summer – these may be used to provide additional purge ventilation.

Mechanical extract systems (a combination of Systems 1 and 3) amounted to 11% of installed systems in the new homes dataset.6

Driven by a combination of the demands for energy-conscious, good-quality and healthy environments, international ‘passive’ design standards, and regulatory requirements, deployment of balanced supply and extract MVHR in domestic and small commercial applications is becoming increasingly common (ADF System 4 – 26% of installed systems in new homes dataset6).

This provides a controllable, balanced ventilation system that would typically employ a parallel plate heat exchanger to recover heat from the discharge air, with a bypass arrangement to allow ventilation without heat recovery when ‘free’ cooling is required.

The heat recovery will significantly reduce the ventilation heating demand. As the supply air is drawn from a ducted inlet, in a location that is least affected by external sources of pollutants – such as at roof level – there is no need for background ventilators.

Filters are used on the inlet air stream to (at least) prevent insects and large particulates being drawn into the building. However, there are opportunities for increasing filter efficiency to remove smaller particulate matter and, potentially, other pollutants. Although MVHR can be applied to a single space, it is more normally used to provide balanced ventilation throughout all occupied spaces in a building.

MVHR is only practical in buildings with good airtightness – this is discussed more fully, with further explanation of the application of MVHR, in CPD Module 141, CIBSE Journal, February 2019.

The siting of the MVHR unit should be such that the building user can safely and easily access the unit, to change filters and periodically clean the heat exchanger.

Systems that include electrically powered fans are likely to need to conform to specific fan power (SFP) limits defined by regulatory requirements (such as those in Table 1 of the England Domestic Building Services Compliance Guide9).

The SFP will depend on the characteristics of the ductwork systems and the pressure drop through any heat-recovery device, the filters, and the total efficiency of the fan. More exacting filtration is likely to increase the fan power, and that may make it more challenging to meet these regulatory requirements.

In recent years, there have been many reported incidences of overheating in homes. Every effort should be made to mitigate the risks of overheating through the building design, as explained in CIBSE TM59.10

However, there are likely to be many instances where it is not practicable to maintain comfortable and healthy internal peak temperatures using natural, or ‘free’ cooling methods. Manufacturers are developing products that extend the traditional MVHR unit, by adding a water coil for the outdoor air after the air has passed through the heat recovery section and before the air is supplied into the space.

The coil can be used to provide heating or cooling to the air – for example, the water being delivered from a thermal store that seasonally stores heated or cooled water. The heating/cooling source of this could, for example, be heat networks and heat pumps (integrated with heat networks or domestic hot water heat recovery, or air sourced).

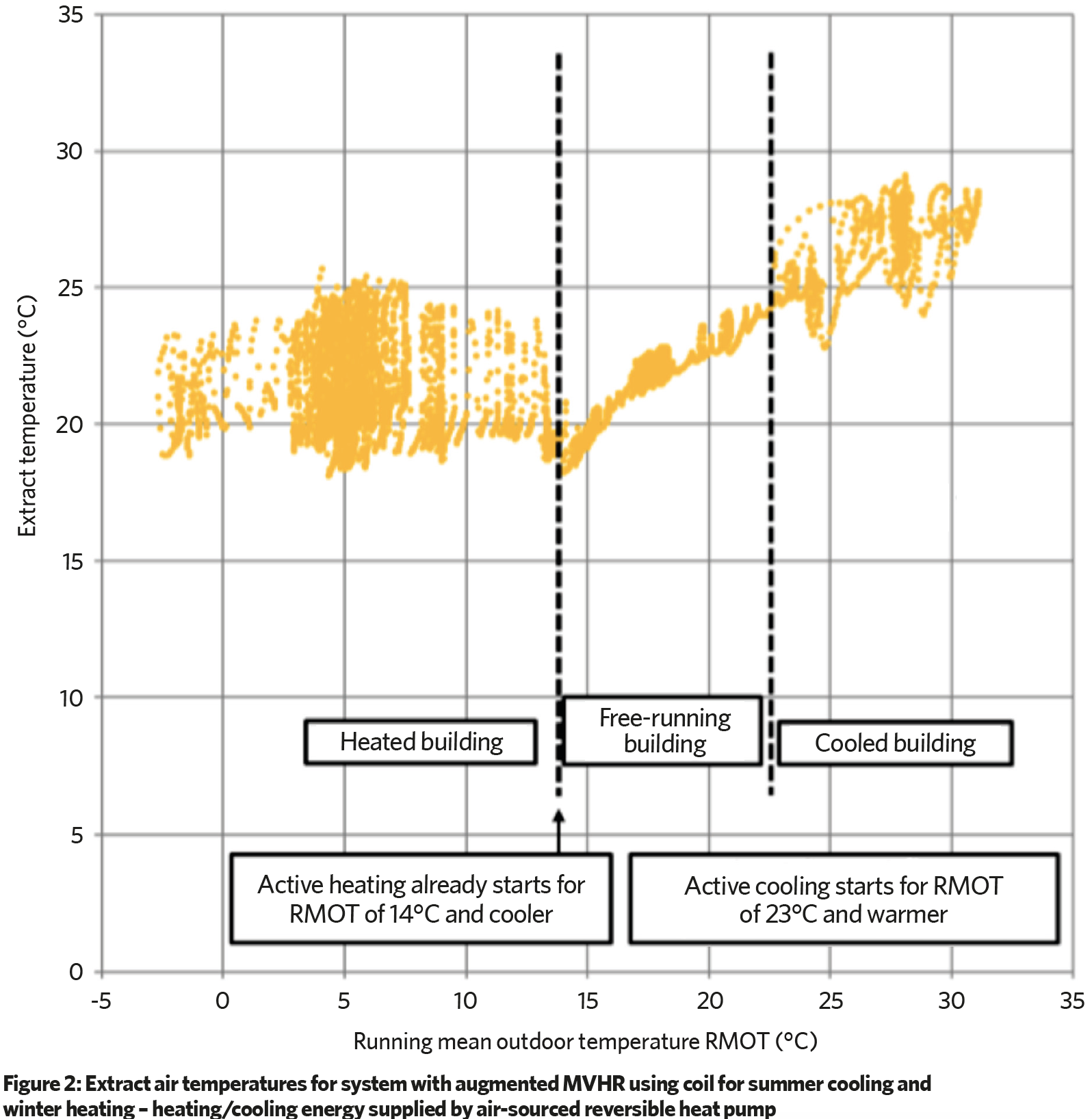

In an example system in Modena, Italy (in the northerly part of the subtropical climate zone), a reversible heat pump was used to supply the energy to the thermal store for a home that had been designed as a near-zero energy building.

The monitored extract air temperatures plotted against the running mean outdoor air temperature (RMOT), shown in Figure 2, indicate the seasonal operation of the system. Automatic scheduling ensured that cooling was only employed where, in this case, RMOT exceeded 23°C (resulting in room temperatures circa 25°C) – the room setpoint temperature being reset by the outdoor temperature.

Adding active cooling to the MVHR unit will increase the energy use of the building, but may enable the building to be used as a healthy and comfortable environment when otherwise it may have been unusable. Adding cooling to a domestic ventilation system needs very careful consideration, particularly in a temperate location. Similar systems have already been successfully installed across Europe and the US.

© Tim Dwyer, 2020.

Further reading

There are many sources for further reading, including these publications:

CIBSE TM40 (2006) Health issues in building services provides one of the most consolidated collections of CIBSE references for air quality related to ventilation.

CIBSE KS17 Indoor Air Quality and Ventilation provides an accessible summary of assembled information taken from CIBSE publications and other standards.

The Zero Carbon Hub 2013 report Mechanical ventilation with heat recovery in new homes includes useful, well researched MVHR good practice in section 4.

And the soon-to-be-published update to CIBSE TM40 Health and wellbeing in building services will provide current thinking on the requirements for safe and healthy internal environments.

References

1 The inside story: health effects of indoor air quality on children and young people, Royal College of Physicians/Royal College of Paediatrics and Child Health, January 2020.

2 The not-so great outdoors, Ribble Cycles blog accessed 5 February 2020.

3 ww3.arb.ca.gov/research/resnotes/notes/94-11.htm – accessed 7 February 2020.

4 The Lancet DOI: (10.1016/S0140-6736(17)32345-0).

5 www.nice.org.uk/guidance/ng149/chapter/Recommendations#architects-and-designers – accessed 5 February 2020.

6 Crawley, J, The relationship between airtightness and ventilation in new UK dwellings, CIBSE BSERT, 2019, Vol. 40(3) 274–289.

7 Building Regulation – Ventilation – Approved Document F1, HM Government, 2018 Means of ventilation.

8 Domestic Ventilation Compliance Guide: 2010 Edition, UK DCLG, 2011.

9 Domestic Building Services Compliance Guide – 2013 edition – for use in England, HM Government, 2018.

10 CIBSE TM59 Design methodology for the assessment of overheating risk in homes, CIBSE 2017.