Credit: iStock: northlightimages

This CPD article will consider the application of distributed mini heat pumps that share a common ground loop as a means of reducing operational carbon impact – and cost – as part of the holistic improvement of this vital housing stock.

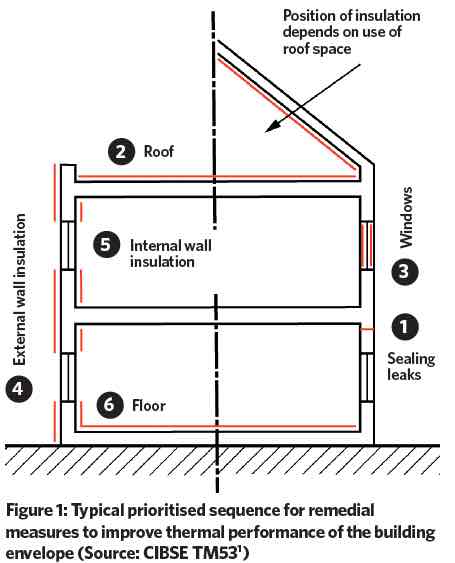

In any refurbishment project, the essential first stage – following appropriate surveys and life-cycle cost benefit analysis – is to ensure that the building fabric is refurbished to provide an appropriate thermal, and environmental, performance. As well as considering the cold weather performance of the building, it is increasingly important to establish that the building alterations minimise the potential for overheating. (A methodology to examine this is provided in the recently published CIBSE Technical Manual 59 Design methodology for the assessment of overheating risk in homes.) A typical prioritised order for undertaking remedial measures in housing is illustrated in Figure 1.

In parallel with planning the fabric improvements, the environmental (heating and possibly cooling), water and public health systems – as well as other installed systems – would be evaluated. It is, in any case, good practice to consider the whole integrated building system when determining the optimum solution. Not understanding the impact of all the system’s components can, for example, lead to costly additional building work or – worse still – unintended consequences, such as penetrations through vapour barriers, rain shields and fire barriers.

Potential options for the heating systems are numerous and include sourcing ‘renewable’ heat; district heating; upgrading existing systems; and improving controls. Existing installed systems should be thoroughly assessed to establish the practical viability of upgrading the systems to meet – and potentially exceed – current standards. This could be through equipment refurbishment – such as new heat exchangers, improved heat emitters, valves, sensors and controls – or simply by methodical recommissioning.

The selected solution will be determined by: specific factors that relate to the building type and use; level of user engagement; the availability, cost and environmental impact of energy; system operational characteristics; monitoring needs; and maintenance requirements.

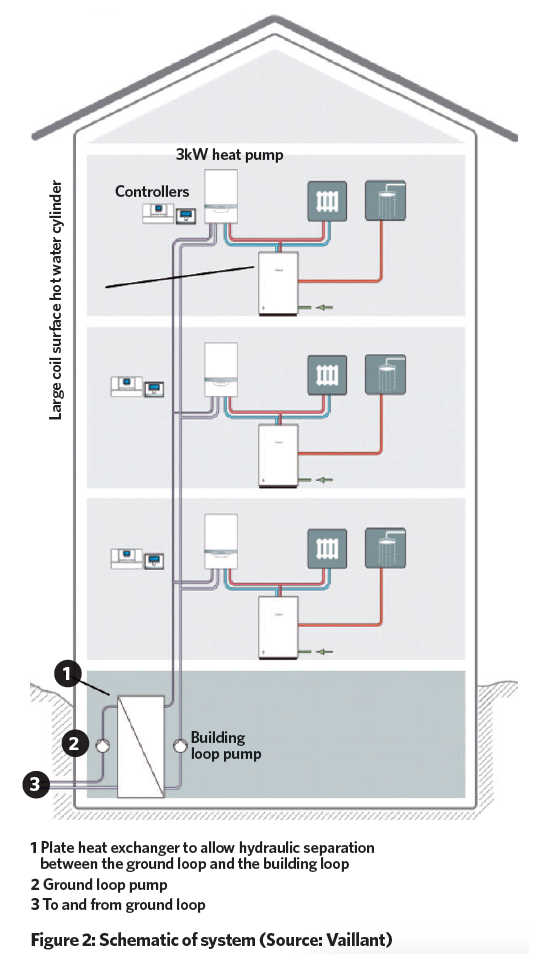

This article will focus on a relatively innovative solution that employs distributed micro heat pump systems, which draw heat from a shared ground loop and are located in individual apartments that have good thermal performance (typically through refurbishment), as illustrated in Figure 2. This concept has been made possible through the recent development of wall-hung mini heat pumps that can be used to provide heat for space heating and domestic hot water (DHW).

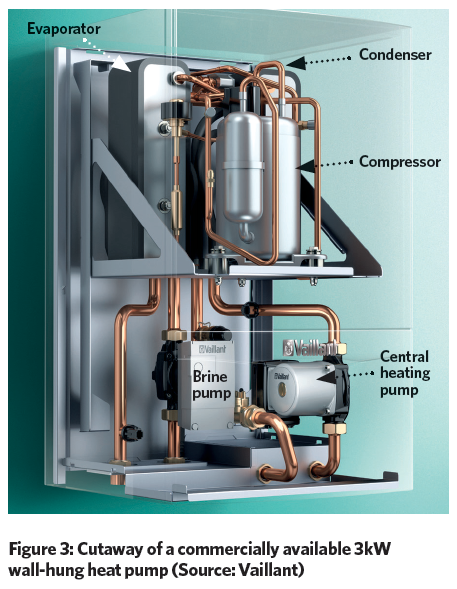

An example of a wall-hung 3kW mini heat pump is shown in Figure 3. This is driven by an almost-silent rotary vane (rolling piston, fixed vane) compressor (see boxout). The evaporator of this vapour compression system draws heat from the ground via the circulation of ‘brine’ through a ground loop and an internal building riser loop. The circulating fluid used in the closed-loop ground heat exchanger is usually water with antifreeze (commonly ethylene glycol and propylene glycol) added to provide protection from freezing, plus inhibitors to prevent corrosion and bacterial growth. This offers freeze protection down to at least -15°C.2

The ground temperature seasonally fluctuates to depths of about 15m where the temperature is approximately equal to the mean annual air temperature (8-11°C in the UK). Below this, the ground temperature increases at, on average, 2.6°C per 100m because of heat flowing from the interior of the Earth. Mean temperatures at 100m depth in the UK vary between about 7°C and 15°C. Hence, in winter, the ground temperature is higher than the air temperature, while in summer, it is lower than the air temperature.3 Careful site assessment is required to determine an appropriate ground loop design and, particularly where bore holes are being considered, the input of specialist geologists. A diversity factor would not normally be used when sizing the ground loop or the main riser pipe, and so both should be of a suitable size to deliver the required heat when all the heat pumps are operational.

A high-effectiveness, low-pressure loss plate heat exchanger is typically required between the ground array and the internal building riser loop, to provide a hydraulic break. The internal riser must be sized to support all heat pumps running at the same time – the heat pumps may have specific pressure limitations that influence the riser design. Circulation pumps will be required for the ground array as well as for the internal riser, and both these will need to be sized for full flow requirements – careful system design is important to ensure effective hydronic operation. Since the circulating fluid is likely to be below the dew-point temperature of the surrounding air in the riser, proper insulation and vapour barriers are essential.

The tenant maintains control of the heating and hot water, and pays for it through their normal electricity supply bill. This could provide opportunities for more responsible use of energy. However, compared with a centrally supplied, fixed-rate heating system, there may be a risk of tenants maintaining unhealthily cold conditions because of fuel poverty (despite the actual operational cost being lower than with the old systems). The heat is generated and used in the immediate occupied area, so no heat is lost transporting it around the building –contributing to the reduced operating costs.

Since the system is driven by electricity, there are zero emissions at the point of use. This can be particularly attractive in helping to improve air quality in cities. In the UK, the operator benefits from the commercial renewable heat incentive (RHI) over 20 years (subject to individual apartments maintaining an up-to-date energy performance certificate (EPC)), giving the landlord a confirmed income stream that can be used – among other things – to offset the pumping and maintenance costs. (This is subject to the rules as published by Ofgem – see www.ofgem.gov.uk.)

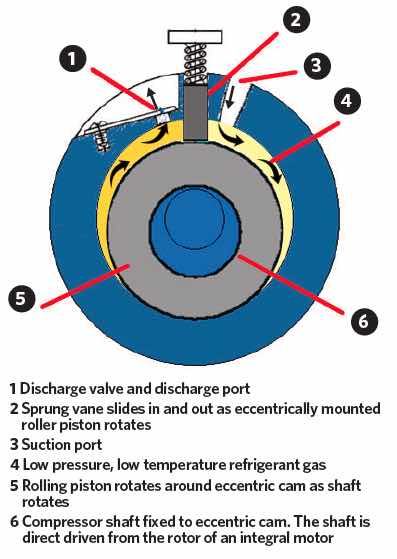

Rotary vane compressor

This type of compressor (illustrated left) is typically found in domestic refrigerating machines and comprises a rotating shaft connected to an eccentrically mounted roller. It is a positive displacement device but, unlike a reciprocating compressor, the continuous rotary action is not subject to impulsive vibration – the machine also has very few moving parts. A single vane – or blade – is spring-mounted in the non-rotating cylindrical block. The rotating motion of the roller causes a reciprocating motion of the sprung vane, so providing a separation between the incoming cool low-pressure refrigerant gas and the higher pressure, higher temperature leaving refrigerant.

Figure 4: Schematic of a rotary vane compressor driven by integral two-pole motor that rotates at 2,850rpm (with a 50Hz electrical supply)

UK 16-floor residential tower block example application

A generic 16-floor, 95-apartment southern England lightweight concrete tower block that was originally completed in the mid 1960s, with an average apartment size of 50m2, is used as an example. The building is currently served with an oil-fired heating scheme. A model has been created by the heat pump manufacturer to explore the opportunity to apply distributed mini heat pumps to serve the needs of the tenants as part of an integrated building refurbishment.

The load assessment confirmed that each flat could potentially be serviced by its own 3kW wall-hung R410a heat pump and DHW cylinder. The low-grade heat from a ground-sourced building loop is sufficient to deliver flow water temperatures of up to 60°C from the heat pump (the coefficient of performance (COP) of the heat pump will reduce as the output temperature rises; however, even at 60°C, the COP is approximately 2.5). This is then used to heat the apartment through oversized radiators and to produce DHW through a 150L ‘heat pump’ unvented cylinder (this has a larger coil than traditional hot water cylinders).

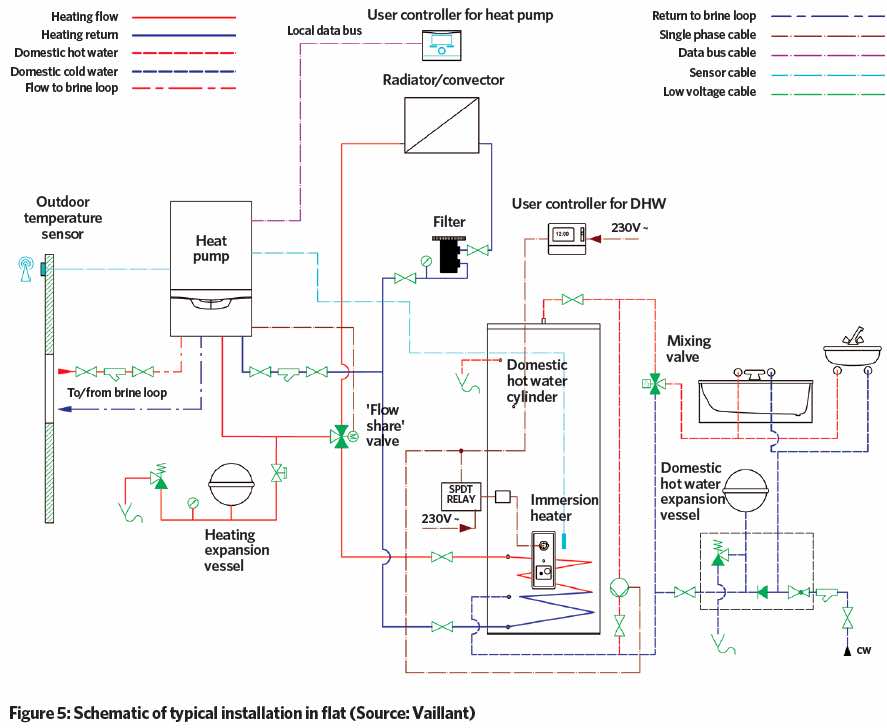

An example system, to serve a typical two-bedroom apartment of 60-70m2 (as shown schematically in Figure 5), was modelled with an annual heating requirement of 7,115kWh and a DHW heating requirement of 2,292kWh.

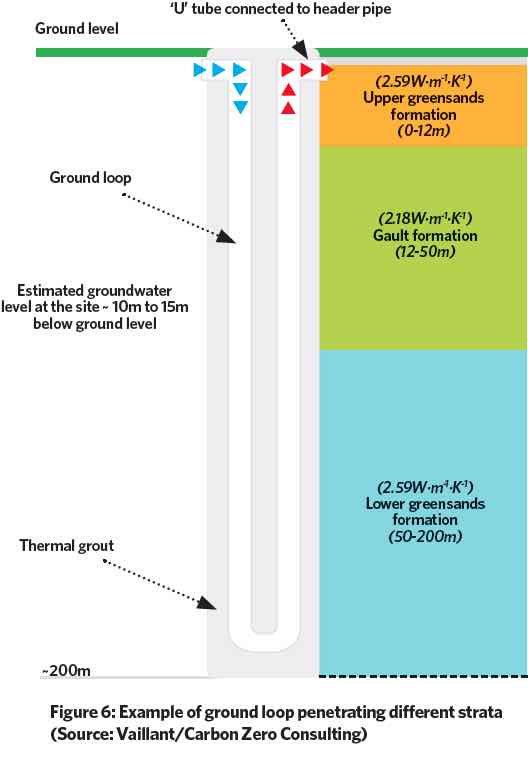

The ground array was sized to deliver brine to the heat pumps at a temperature of between 0°C and 8°C. The total length of borehole depends on the specific ground conditions, as this affects the opportunity for heat transfer. As an example, if the ground provided a relatively modest 38W per metre of borehole, then 4,500m of borehole will be required – this could be provided by 33 boreholes, each 130m deep. (Operating for 2,400 hours per annum, BS EN 154504 indicates that a borehole in dry sediment can provide 20W per metre, and that ‘normal’ underground and water-saturated sediment can provide 50W per metre.) A sketch of a ground loop for a site like this tower block is shown in Figure 6.

Considering the required heating temperature and predicted range of borehole extraction temperatures, the seasonal heating COP (SCOP) of the 3kW heat pump is 3.7 and so the heating annual electrical requirement is 1,922kWh. To provide DHW at an appropriate temperature, the average COP was estimated as 2.8 and so the annual electrical energy requirement is 818kWh. The total annual energy requirement is 2,740kWh – so, based on an electrical cost of 13p per kWh, the estimated annual fuel cost is £356.20 per apartment.

The notional basic carbon saving of producing heat for the apartments can be estimated based on the annual heat requirement of 583,989kWh. Assuming the efficiency of the existing oil plant room is 75%, the annual carbon emission is approximately 210 tonnes5 CO2. This compares with the heat pumps that have an overall SCOP of 3.47 (taking account of a reduced COP to meet the DHW needs) generating approximately 69 tonnes5 CO2. So, notionally, the distributed mini pump system would save more than 140 tonnes CO2 each year, in addition to removing local pollutants that are otherwise emitted from the oil burning plant.

The potential RHI – which is payable over 20 years – is split into two annual tiers, with the first 1,314 operational hours paid at £0.0895 per delivered kWh heat and the remaining at £0.0267 per delivered kWh heat. The total annual heat requirement for the building has been calculated as 583,989kWh. If supported by metered consumption (which would be feasible since all the mini heat pumps are equipped with heat meters and networking capability), the RHI payment could provide an annual payment of £36,469 (if tenants were to use the systems under the conditions modelled).

© Tim Dwyer, 2017.

References

CIBSE TM51 Ground source heat pumps provides a comprehensive introduction to the overall technology and application and is well complemented by BSRIA’s Heat pumps – A guidance document for designers.

1 CIBSE TM53 Refurbishment of non-domestic buildings, CIBSE, 2013

2 CIBSE TM51 Ground source heat pumps, CIBSE, 2013

3 Ground Source Heat Pumps, British Geological Survey – accessed 1 July 2017

4 BS EN 15450 Heating systems in buildings – Design of heat pump heating systems,

BSI 2007

5 Based on data from Greenhouse gas reporting – Conversion factors 2016, BEIS – accessed 1 July 2017