If appropriately applied, the air source heat pump (ASHP) can be an effective means of providing heating energy for buildings in temperate climates, such as that of the UK. Although they do not currently attract any Renewable Heat Incentive (RHI) payments, the recent changes to the permitted development rights in England for ASHPs have eased the planning requirements for domestic installations (and some currently attract a one-off Renewable Heat Premium Payment1). So they are increasingly likely to come under consideration as a means of providing heating and hot water. This article considers some of the current requirements and trends in their application.

Unlike other ‘renewable’ technologies, the application of ASHPs will still use electricity or gas to fuel them, so may not be seen as the purest form of renewable heat but, with appropriate application, they can effectively draw on the practically inexhaustible and freely available source of heat stored in the air.

Appropriate use of an electrically powered heat pump can be cheaper than using an oil-fuelled or condensing-gas boiler, as well as reducing operational carbon emissions. Based on data collected in real applications by the Energy Savings Trust, properly installed and operated systems can provide typical savings2 in a three-bedroom semi-detached house of £380 per year (or 4,440 kg CO2 equivalent) when replacing electric heating, and £80 (or 810 kg CO2 equivalent) per year when supplanting oil heating (and, with the better performing systems, this can rise to £610 and £310, respectively, and can even save £130 when compared to gas).

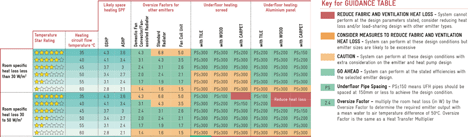

Figure 1: Monovalent heat pump installation sized at 100% of heating design load requires supplementary heating when outdoor temperatures are below design conditions.

Operational efficiency

The efficiency, in terms of coefficient of performance (COP) (see CIBSE Journal October 2011, p51, for definition), is variable depending on the operating conditions and the refrigerant used, but can range from under 1 (when external temperatures are very low and the unit produces almost the same heat energy as the electricity it consumes) to COPs of 3 and above under spring/ autumn conditions when supplying low- temperature heating systems.

The majority of heat pumps currently in the marketplace are best suited for use with low temperature systems, such as underfloor heating at 30-45C, fan coils at 35-55C, and radiators sized to operate at 45-55C. Clearly, this is a temperature below that needed for the safe operation of domestic hot water where, to reduce risk from legionella, any hot water storage needs to be regularly heated to 60C3. In the case of a standalone heat pump system (known as a ‘monovalent’ system) that is being used to heat domestic hot water, this requires the use of a direct electric heater for brief periods to bring the stored water to an adequate temperature for legionella protection.

ASHPs are recognised in the England and Wales Building Regulations Approved Document Part L4 as being appropriate for heating buildings when they have a COP of not less than 2.2 when being used for space heating, and not less than 2.0 when also being used for heating domestic hot water. These are based on measurements being made at standard external temperatures of 7C. This happens to be just below the average outdoor dry bulb temperature in southern England over the ‘heating season’ for housing, assuming that houses require some form of heating as outdoor temperatures fall below 15.5C (the base temperature used in the degree-day energy estimation method). With improved standards of construction, the point at which modern housing needs heating will be somewhat lower than this (probably nearer to an outdoor temperature of 11C). This means that the average temperature throughout the heating season will also be somewhat lower, at around 5C or 6C.

Figure 2: An air source heat pump with external evaporator unit, internal condenser unit and matched thermal store.

And, of course, the main weakness for ASHPs is that as the temperature of the outdoor air reduces (in winter), the COP will reduce – just when there is the greatest need for heating. So, any meaningful statement of performance should consider the operation over the whole working ‘season’. The seasonal performance factor (SPF) (see CIBSE Journal October 2011, p51, for definition), which considers the ratio of annual useful heat produced compared to the energy supplied, allows for the inevitable changes in COP as the evaporator and condenser temperatures vary due to altering external temperatures and internal load requirements. It will also account for other de-rating factors, such as the de-icing cycles required to keep the evaporator clear of ice at low outdoor temperatures, as well as accounting for parasitic power used in fans and control systems. For ASHPs supplying heating and hot water systems, Part L requires the SPF to be a minimum of 2.7 for new build and 2.5 for retrofit installations (this is in line with the requirements of the very useful BS EN 15450:2007 – Heating systems in buildings – Design of heat pump heating systems).

In 2010, the Energy Saving Trust5 (EST) reported relatively poor seasonal performance of retrofitted heat pumps in domestic applications, using a slightly different measure called ‘System Performance’ that also takes account of energy used in controlling and applying the heat to the building load. Half of the installations surveyed had a system performance of 2.2 or less – although there was no specific quality assurance in place when these heat pumps were installed. Future COPs (considering the ideal ‘Carnot cycle’ that determines the thermodynamic upper limit of ‘heat engines’) may theoretically reach towards seven and, indeed, European experience has shown SPFs in their more mature, experienced markets to be significantly higher than the majority of those in the EST report.

Microgeneration Installation Standard: MIS 3005

As part of the Microgeneration Certification Scheme (MCS), and in an attempt to improve standards, the Microgeneration Installation Standard MIS 30056 sets out the required procedure for contractors for the design, selection and installation of heat pumps up to 45kW heat output. This will range in application from domestic to small commercial premises. The products themselves are also certificated by the MCS as meeting appropriate standards. The objective of the government’s microgeneration strategy is an attempt to create conditions under which technologies, such as ASHPs, become a more realistic and acceptable alternative energy solution. As well as being evidence of good practice, MCS compliance is required if the installation is to take advantage of the recently introduced permitted development rights in England, or is being used to gain any government funding such as a Renewable Heat Premium Payment7 or, potentially, the Renewable Heat Initiative payments that could be commencing for ASHPs later this year.

The most recent revision to MIS 3005 (version 3, which comes into effect from 1 February 2012) requires that if the heat pump is the only source of heating (a ‘monovalent’ system) then it be selected so that it provides at least 100% of the calculated design building heat loss (determined using standard methods such as those given in BS EN 128318 or CIBSE Guide A). The key impact of this new requirement is that this is the heat pump rating – excluding any supplementary electric heating – supplied as part of an integrated ASHP package. This will lead to larger (and probably more expensive) units being installed, but should ensure that there is less use of direct electric heating, which has been a concern in installations to date.

If the heat pump is sized to operate at 100% output at the design heat loss, then at times when the external temperatures fall below design conditions, additional heating will be required (as in Figure 1). Using MCS-recommended design conditions, this could be in the order of 90 hours per year and, in a monovalent system, this heating is likely to be provided by an associated electric heater. An alternative is to ‘oversize’ the ASHP to satisfy the extreme conditions, but because the COP drops as the outdoor temperature reduces, there is likely to be a disproportionate increase in heat pump size for the relative short period during the year that the additional load will be used. Oversizing is likely to increase on/off cycling at moderate loads, which may reduce the SPF. For the majority of traditional installations, there is a supplementary heat source that will also be required to satisfy top-up loads for the domestic hot water requirements.

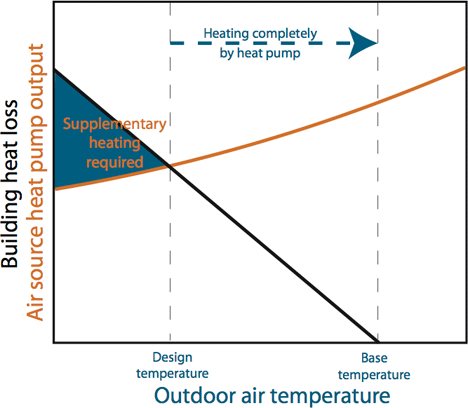

Figure 3: MIS 3005 Heat Emitter Guide for Domestic Heat Pumps, showing part of the matrix to establish appropriate heat pump/heat emitter design criteria, based on room heat loss and heating flow water temperature.

For bivalent systems (those that have an alternative heat source, such as a gas or oil boiler) the combined installed design load should satisfy the full design heat loss – again, without including the output of an electric heater.

To maximise the SPF, and reduce cycling, there should be some storage element within the system, as is frequently offered in a package such as that shown in Figure 2.

ASHPs are also regularly used to provide cooling in commercial applications using ‘reversible’ systems (the function of the evaporator and condenser being reversed), which frequently uses variable refrigerant flow and building zoning to allow controlled concurrent heating and cooling across the building. Where there is a consistent diverse heating and cooling load, there can be a strong case for using cooling by effectively moving the heat from the overheated areas to the areas with a heating need, using the heat pump technology. However, the use of cooling on its own, in both commercial and domestic premises, can normally be – and, for environmental and energy use reasons, should be – avoided in all parts of the UK. However, if cooling is used, the removed heat should – wherever possible – be applied to domestic hot water storage.

Guide for domestic heat pumps

To size heat pumps for heating systems requires some fairly standard calculations that should be within the capabilities of design engineers. However, to assist in the appropriate application of heat pumps to both new and retrofit applications, a supplementary guide to the MIS 3005 has recently been published. The Heat Emitter Guide for Domestic Heat Pumps attempts to provide a relatively simple (paper- based) tool to establish, prior to installation, the capability of both existing and new heating systems (excluding domestic hot water) to employ heat pumps.

The document is particularly useful when assessing the potential for existing heating systems to be reused when installing heat pumps. It provides a simplified method to assess the suitability of different heating emitter systems, including radiators and fan convectors, in existing properties when replacing gas or oil boilers. Since ‘traditional’ systems were typically designed with mean heating water temperatures of around 76C (far higher than is currently available from heat pumps), the guide determines the opportunities for using lower heating flow temperatures by examining the degree of oversizing in the existing heating distribution system. The heat emitters may have been originally oversized to allow for cold start up, to provide a ‘safety margin’ or simply for aesthetic reasons. And subsequently, as a result of energy saving measures (for example, draught proofing, improved thermal insulation and double glazing) the heating loss in the building may have reduced substantially below the available output of the heating distribution system. The heat loss to potential heat output ratio is termed the oversize factor.

Whatever the reason for the system’s oversizing, it provides an opportunity to increase the operating performance of a heat pump, since larger heat emitter areas allow lower water flow temperatures to meet the required heat output. The combination of oversize factor and heating system flow water temperature is used to give a predicted SPF for the retrofitted heat pump installation.

For new buildings, the guide provides a matrix to assist in the selection of heating systems that are likely to operate at an appropriate SPF. This uses a combination of room heat loss, heating emitter types and heating flow temperatures to assess the likely SPF for air (and ground) source heat pumps. It identifies the most appropriate solutions, using a ‘traffic light’ colour coding system, in terms of the required ‘oversize factor’ for radiators and convectors (i.e., the multiplier of their catalogue output at an emitter-room temperature difference of 50K), and ‘pipe spacing’ (PS) for underfloor systems, related to various floor finishes.

The matrix is shown in Figure 3 and can be freely downloaded from www. microgenerationcertification.org The guide may well assist in improving the application of heat pumps, and provides a quick first feasibility check.

Carbon dioxide heat pumps

The commercialisation of small scale heat pumps employing CO2 as a refrigerant potentially offers some key benefits to the domestic and small commercial marketplace. To act as a refrigerant, CO2 uses far higher pressures than HFC refrigerant, making more demands in the engineering of the underlying system. However, the major benefit is that the systems can be designed so that they can efficiently produce heat at 65C – a temperature that can satisfy the requirements of hot water systems, without needing top up supplementary heating.

However, due to the way that CO2 heat pumps work (known as supercritical operation), they require a large temperature drop across the load to achieve consistently good COPs. This means that they are particularly effective when heating up low temperature loads (such as incoming cold water supplying a hot water service) but not so effective when heating the returning water from a heating system. Hence, they are likely to show the greatest benefit where a building has a relatively large domestic hot water load compared with the heating load – a trend that is becoming more likely with increasing building fabric performance.

© Tim Dwyer 2012

For further reading in this area see:

CIBSE Journal, October 2011 pp50-56. The article ‘Hot Prospect’ covers the realities of heat pump application.

The BSRIA guide Heat Pumps – A guidance document for designers (BG 7/2009) provides an excellent overview of heat pump technology and application.

HVCA’s Guide to Good Practice – Heat Pumps (TR/30) covers the practical aspects of installation.

References

- www.energysavingtrust.org.uk/Generate-your-own-energy/Financial-incentives/Renewable-Heat-Premium-Payment Accessed 7 December 2011.

- www.energysavingtrust.org.uk/Generate-your-own-energy/Air-source-heat-pumps

- Legionnaires’ disease. The control of legionella bacteria in water systems. Approved Code of Practice and guidance L8, HSE 2007

www.hse.gov.uk/pubns/books/l8.htm - www.planningportal.gov.uk/buildingregulations/approveddocuments/partl/approved

Accessed 3 December 2011. - Getting warmer: a field trial of heat pumps, Energy Saving Trust, 2010.

- Microgeneration Installation Standard, MIS 3005, Issue 3 2011,

www.microgenerationcertification.org - www.energysavingtrust.org.uk/Generate-your-own-energy/Financial-incentives/Renewable-Heat-Premium-Payment Accessed 2 December 2011.

- BS EN 12831:2003 Heating systems in buildings. Method for calculation of the design heat load.