Sustainability – so often seen as a cost – has proven to be an asset at Cathedral Hill Industrial Estate.

When the 30-year old, 13-unit development was acquired by Diageo Pension Trust in October 2019, rental value was 33% below the average for Guildford, Surrey. Now, after a £10.6m deep refurbishment, the scheme is Breeam Excellent certified and on target for net zero carbon whole life, and rental values have increased by an impressive 220%.

This remarkable achievement was recognised at this year’s CIBSE Building Performance Awards, where the scheme won Project of the Year – Portfolio Workplaces. The category judges praised it as an ‘outstanding example of how regeneration can benefit business and the environment’.

The focus on sustainability was to increase the value of the pension fund’s asset. While the bones of the estate were good, the industrial units were dated in appearance, with crinkly asbestos-cement sheet roofs and single-glazed windows. A lack of roof lights meant there were poor levels of natural light.

Maintenance costs were high, and although the average Energy Performance Certificate (EPC) ratings were C and D, the units performed poorly in practice, with inefficiencies reflected in energy use and running costs. This also meant they would fail to comply with tougher Minimum Energy Efficiency Standards (MEES) for commercial properties, due in 2030.

Minimum Energy Efficiency Standards (MEES)

MEES regulations for commercial properties in England and Wales require landlords to ensure that let properties have a minimum EPC rating of E. This requirement was implemented in 2018 and initially focused on new and renewed tenancies. From 1 April 2023, the scope of MEES expanded to include existing tenancies, making it illegal to continue letting properties with an EPC rating of F or G. Future regulations aim to further improve energy efficiency, with a long-term target of EPC B for all private-rented commercial properties by 2030, where cost-effective.

A brief drawn up by Savills Investment Management and Savills UK Building & Project Consultancy, working with sustainable built environment consultants SRE, set out the initial proposals for the scheme’s sustainable retrofit.

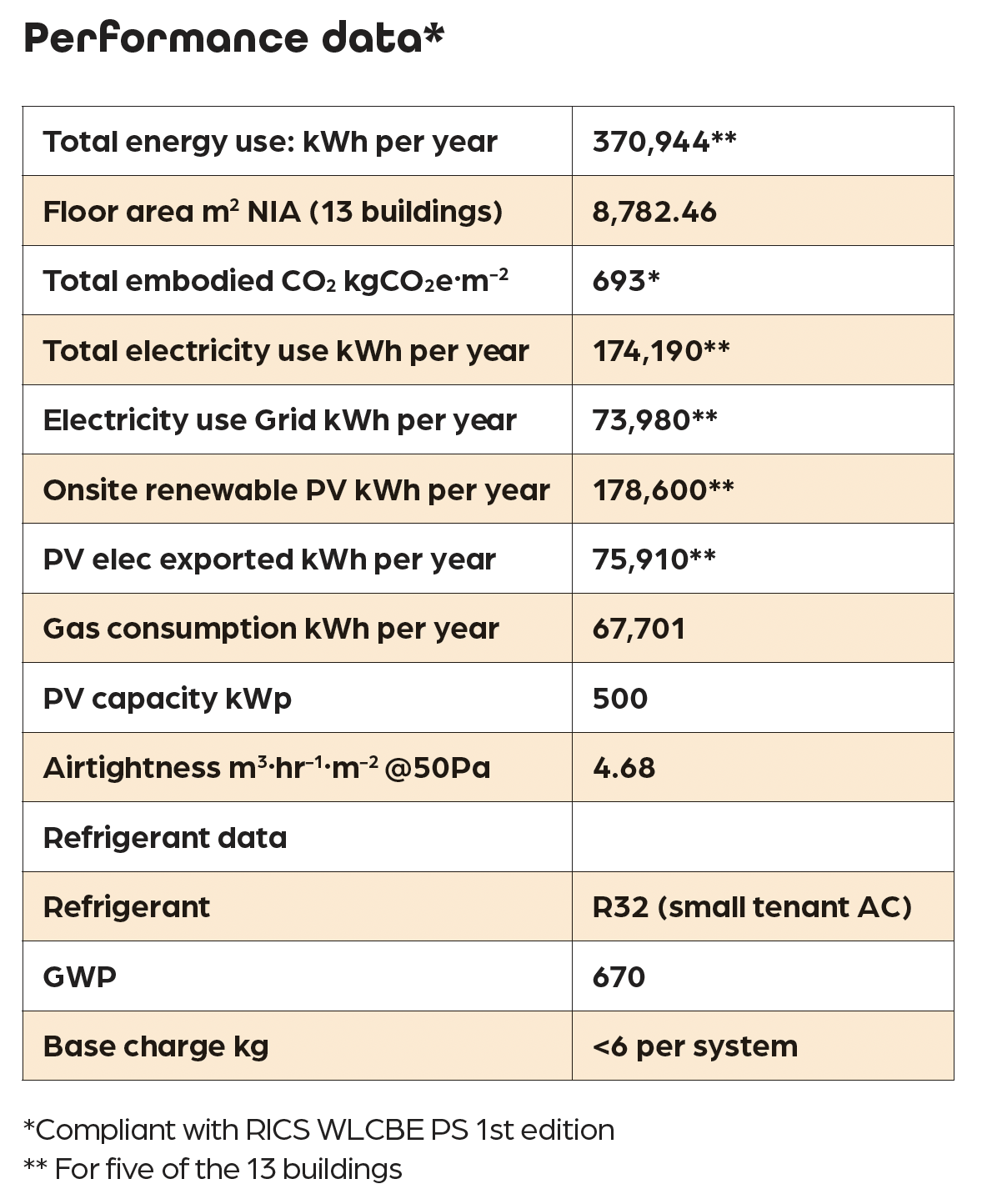

SRE also undertook a whole life carbon assessment (WLCA) for the base build at the design phase, to account for the additional embodied CO2 emissions resulting from the refurbishment of the industrial units and the external areas, and to assess potential savings in operational emissions.

The walls of the units were over-clad with insulated cladding to improve their thermal performance and appearance

The WLCA was based on RICS guidance, with the baseline set as the site at the time of the works. It was an approach that ensured all demolition material removed from site and new materials added under the redevelopment were accounted for within the assessment process. According to Savills, the aim of the assessment was to help it develop a strategy for the refurbishment of the site to be deemed ‘zero carbon’. ‘Net zero wasn’t really talked about in 2019, but we felt that it was a good thing to aim for in terms of adding asset value,’ says Anna Maclean, SRE’s CEO.

The focus of the refurbishment was on fabric energy efficiency improvements. Eleven of the units had tenants in place, so Savills’ approach was to upgrade one unit at a time. The two vacant units were upgraded first to allow incumbent occupiers to move into the modernised, energy efficient units. This freed up the next units for refurbishment.

‘Savills only changed the things it had to, but it was an opportunity to make everything look sleek and modern at the same time,’ says Cara Palmer, a director at SRE.

Servicing of the units is down to individual tenants’ requirements, similar to a Cat A office fit-out. Nevertheless, gas supply was removed from the majority of units, with the exception of two of the tenanted workshops where it was a requirement for industrial processes.

A major element of the works was the removal of the asbestos-cement roofs and their replacement with energy efficient insulated panels. The roof replacement works included doubling the area of translucent roof lights to reduce the need for artificial lighting.

In addition, the units’ giant access doors were removed and replaced with insulated versions, while the walls were over-clad with insulated cladding to improve the units’ aesthetic appearance and thermal performance. Existing concrete floors were diamond polished, eliminating the need for finishing materials.

Internally, thermal improvements included the addition of insulation between the mezzanine-level offices and the unheated warehouse spaces, to enhance occupants’ thermal comfort. The office areas are now heated by radiant electrical panel heaters.

The single-glazed windows were replaced with top- and side-hung triple-glazed windows, which have 100% opening areas to enable purge ventilation in the summer. A TM52 occupant comfort assessment indicated that, with the windows fully open, occupant comfort could be achieved without the need for mechanical cooling, even for future climate scenarios.

The scheme also included enhancements to the natural environment to improve the appearance and gain additional Breeam points. These included the use of gabion baskets, filled with stone-masonry waste from the site works, to define tenant areas and walkways.

Responsible sourcing helped reduce the refurbishment’s embodied carbon emissions and, as a result, upfront carbon emissions for the base-build refurbishment were calculated at 281kgCO₂ m–² GIA. This compares favourably with the emission limits in the pilot version of the Net Zero Carbon Buildings Standard, which, for 2025, are 600kgCO₂ m–² GIA for offices (whole building) and 310kgCO₂ m–² GIA for storage and distribution facilities

The walls of the units were over-clad with insulated cladding to improve their thermal performance and appearance

Perhaps the most significant intervention from an operational carbon perspective was the addition of a large rooftop photovoltaic (PV) installation. The base-build WLCA showed that approximately 75% of CO2e emissions would come from heating and lighting the units over their lifetime.

To help offset this, 1,250 400W solar panels were installed on the roofs, giving a total installed capacity of 500kWp. While actual power output varies with weather and daylight, the system contributes significantly to onsite generation, reducing reliance on Grid electricity and associated carbon emissions. ‘With a shed, PVs are a no-brainer,’ Maclean says.

One year on from completion of the installation, Savills is reporting total generation from the PVs of 450,000kWh, in line with design predictions, giving a payback of five to six years and saving 82 tonnes of C02e per year (based on UK average Grid carbon factor (2025) for electricity of 0.183kgCO₂e/kWh).

Tenants benefit directly from the power generated by the PVs on the roof of their unit, and from two Tesla Powerwall 2 batteries, giving each unit electrical storage capacity of 27kWh (351kWh total for the site). The batteries enable power to be stored during peak PV generation and allow tenants to import electricity from the Grid when tariffs are low, helping balance the Grid while providing financial savings to the tenants.

‘Most of the units are not air conditioned, so the energy produced by PVs won’t be used all the time – so it needs to be stored on site,’ says Manas Bane, sustainability consultant at SRE.

Rental values on the Cathedral Hill Industrial Estate have increased by 220% since the refurbishment works

Remote display screens are installed in the entrances of each unit, showing real-time energy generation and usage data for the PVs and the battery. This includes energy consumed, generated, charged and discharged, imported and exported. Some occupiers have seen their energy bills reduced to zero or have been able to sell energy back to the Grid. Of the electricity generated by the PVs, 95% is used on site, with 19,600kWh exported to the Grid. ‘All the tenants have an app showing their energy use each day, so they can look at it and feel incentivised to reduce their energy,’ says Maclean.

Part of the WLCA used CIBSE TM54 Evaluating operational energy use at the design stage. This showed the contribution of the PVs and battery storage in reducing operational energy consumption significantly over the lifetime of the building. When considering all units from a shell and core perspective, Cathedral Hill Industrial Estate can be considered net zero operational carbon from cradle to grave (life-cycle stages A-C), including disposal.

While the base build is net zero operational carbon, emissions from tenants’ operational energy and the embodied energy from the tenant fit-out need to be assessed and offset for the estate to be considered net zero carbon. This task is being undertaken as part of a tenant fit-out WLCA.

‘Some of the units have only just reached 12 months occupancy, so we haven’t received a full set of data for those units,’ says Palmer. ‘We’re doing a 12-month review now to advise on operational net zero.’

The ultimate aim for the refurbished scheme is for it to be described as net zero whole life carbon. To achieve this status, however, residual carbon emissions from the retained elements will also need to be offset.

Essentially, Cathedral Hill Industrial Estate is an outstanding example of a more sustainable approach to refurbishing industrial buildings, reusing existing structures and materials, limiting new and high-carbon material inputs, and installing onsite renewable electricity generation systems.

These measures have resulted in substantial operational CO2e savings and, with all units now EPC A or A+, the scheme will no longer face obsolescence under MEES.