CPD sponsor

Off-site manufacture has evolved from an experimental delivery route into a key enabler of consistent, high-quality and low-risk construction. Within building services engineering, prefabricated and packaged systems now underpin many modern methods of construction (MMC). This CPD article examines how PAS 8700:20251 defines the processes that underpin MMC. It explores the role of prefabricated building services systems, platform design and digital coordination in delivering safer, higher-quality and lower-carbon construction outcomes.

Prefabrication is often most visible in high-profile projects, yet the same approach delivers significant value in smaller scale or repeated developments where space, labour and programme constraints make site assembly less practical. By transferring fabrication to controlled factory conditions, assemblies such as plant skids, prefabricated risers and packaged plantrooms can be completed before arrival on site. The factory setting enables systematic testing, consistent welding and wiring, and assurance of workmanship independent of site weather or phasing pressures.

The UK Government established a seven-category definition framework2 for MMC, providing regularised terminology to describe the full range of modern construction methods used in homebuilding. This framework covers pre-manufacturing, site-based materials and process innovation, with categories ranging from 3D primary structural systems (volumetric construction) through to additive manufacturing. The final categories encompass site-based improvements associated with products and processes.

Significantly, an additional Category 0 has evolved in various MMC strategies to capture the foundation activities that make prefabrication effective. It measures the degree of standardisation, stakeholder engagement and digital enablement established before physical manufacture begins.

High Category 0 performance reflects early agreement on repeatable designs, information management and BIM coordination, creating the conditions under which later manufacturing categories can deliver value. Without this groundwork, the benefits of off-site assembly risk being lost to late redesign and interface errors.

The strategic importance of MMC is amplified by current regulatory reform. The principles that govern this approach are consolidated within PAS 8700:2025, Modern methods of construction for new-build residential properties, which provides a UK-wide specification for how design, manufacture and assembly should be managed to ensure quality, safety and long-term performance. PAS 8700 emphasises early coordination, competence and traceability across the whole MMC process. It aligns with the duties established under the Building Safety Act 20223 and the Construction (Design and Management) Regulations 2015.4

The specification requires that key dutyholder roles – including client, principal designer, manufacturer and principal contractor – demonstrate appropriate skills, knowledge, experience and behaviours (SKEB). For building services teams, this means confirming that the engineers responsible for mechanical and electrical design, control integration and commissioning are engaged from the earliest design stages and are competent to deliver systems that will remain accessible, maintainable and verifiable throughout the building life.

Early design coordination is central to the PAS approach. The specification uses the Royal Institute of British Architects (RIBA) Plan of Work as a reference framework, and identifies the importance of a design freeze – typically at Stage 3 or early Stage 4 – after which manufacture can proceed without late design changes. So, for example, for plantroom prefabrication this means that hydraulic, electrical and control interfaces must be fixed and documented before the module enters production.

Late changes to valve configurations, control wiring or access routes can negate the efficiency benefits and create warranty or certification issues. PAS 8700 recommends that responsibilities are recorded in a matrix so that each connection, inspection point and testing obligation is clearly assigned to a named dutyholder. MMC projects do not necessarily follow a linear process and stages can be streamlined or overlap and, as such, the PAS is not restricted to being applied to RIBA-staged projects.

The specification also calls for a formal risk register to be created from project inception, identifying hazards such as fire spread, transport limits, structural interfaces and maintenance access.

For prefabricated MEP modules, risk items may include lifting and cranage, temporary protection of factory finishes or the integrity of joints and fire barriers when modules are connected on site. Each risk is to be rated for likelihood and consequence, with mitigation measures recorded and reviewed at each stage. This structured approach turns qualitative claims about ‘reduced risk’ into a documented process that satisfies regulators and insurers.

Design for manufacture and assembly (DfMA) underpins the PAS methodology. It encourages designers to consider how each element will be fabricated, transported, lifted, installed and maintained before construction begins. In the context of building services, this typically includes grouping main plant items with pipework, pumps, pressurisation units, expansion vessels, filters and control panels into assemblies that can be fully wired and hydraulically tested in the factory.

Each assembly forms part of a standardised ‘kit of parts’ that can be adapted to different projects with minimal redesign. PAS 8700 links this approach to the Construction Product Quality Planning (CPQP) framework and to the ‘golden-thread’ principle of maintaining a permanent digital record of each component and test certificate.

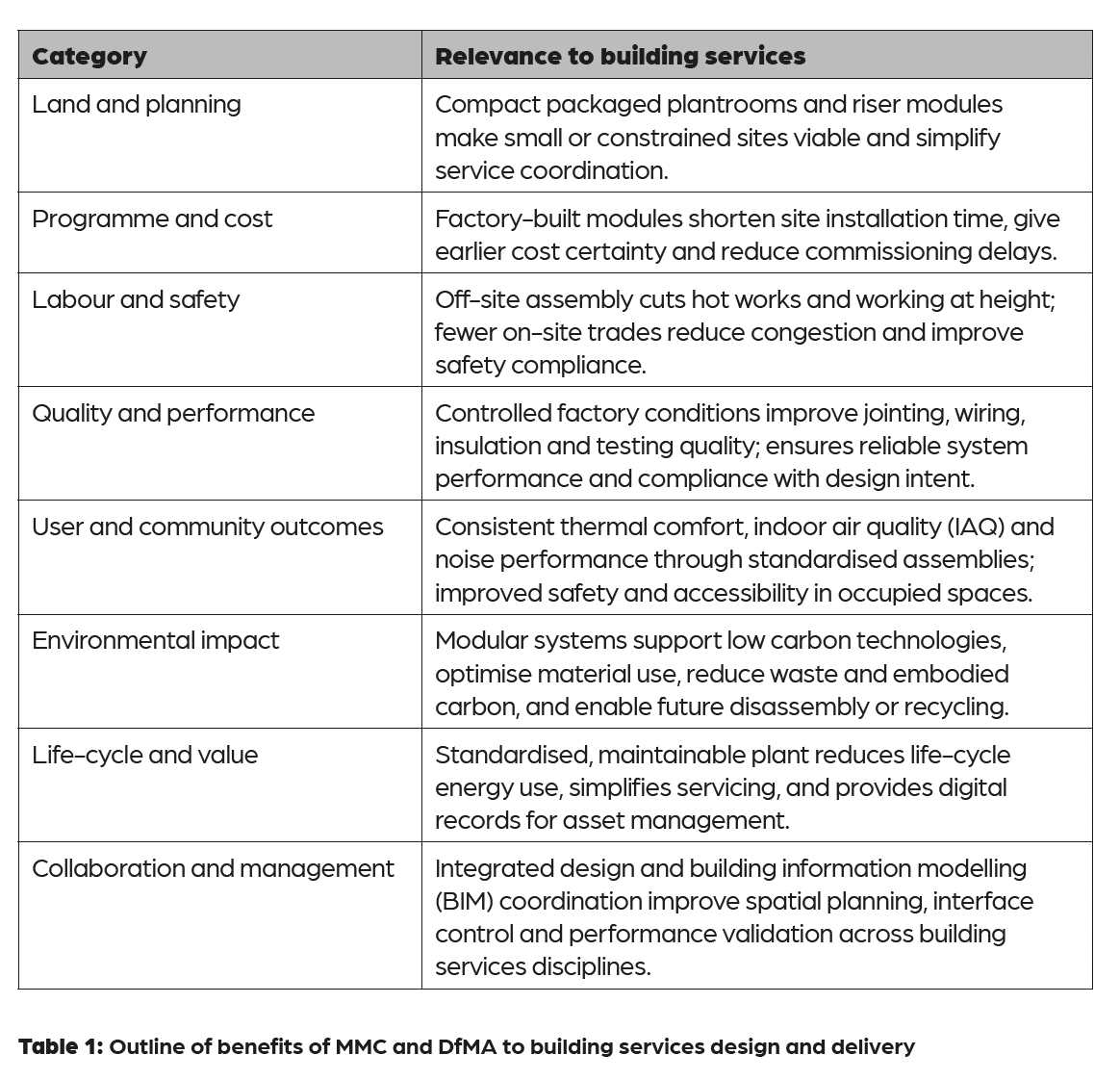

The benefits of MMC and DfMA extend directly to building-services design and delivery. For heating, ventilation and air conditioning (HVAC) and other mechanical, electrical and plumbing (MEP) systems, factory fabrication and digital integration can improve safety, quality and whole-life performance, while accelerating installation and reducing waste. The summary in Table 1 outlines how these outcomes translate specifically to building services applications.

Interfaces between factory-built plant and site systems must be coordinated digitally, typically through a federated building information modelling (BIM) model, and validated physically during installation. PAS 8700 requires that tolerances, movement allowances and sealing arrangements are defined before manufacture.

In building services applications, this includes confirming that pipework penetrations, fire stopping and acoustic seals can be completed without dismantling protected elements. These details are often minor in appearance but critical to achieving compliance and avoiding future claims.

Factory acceptance testing is required for all assemblies that can be safely powered or pressurised before shipment. Pressure tests, electrical continuity checks, and control verification must be documented, witnessed where appropriate, and recorded as part of the quality file. On site, systems are to be commissioned in accordance with established codes such as CIBSE Commissioning Code M for management,5 BESA DW 1446 for sheet-metal ductwork, DW 1437 for leakage testing, DW 1548 for plastics ductwork, BS 75939 for the preparation and maintenance of heating and cooling water systems, and BS 767110 for electrical installations. By citing these standards, PAS 8700 anchors factory prefabrication within the same compliance framework as traditional installations.

Clause 8.7 of PAS 8700 deals specifically with building services. It requires that systems are designed for manufacture and assembly, that distribution routes maintain airtightness and insulation continuity, and that service penetrations do not compromise fire or acoustic performance.

Services must be accessible for maintenance and replacement without removing safety-critical structural or fire-resisting components. Thermal and acoustic performance, airtightness and indoor air quality (IAQ) are treated as measurable outcomes. These provisions align directly with CIBSE Guide B and with Part L of the Building Regulations, ensuring that off-site construction supports rather than bypasses regulatory expectations.

PAS 8700 defines the need for a factory production control system with inspection points agreed with the building control body and warranty provider. Components must be labelled, traceable and protected during transport. Deliveries must be accompanied by documentation identifying lifting points, weight, centre of gravity, and handling methods.

On site, inspection records, photographic evidence and certificates form part of the quality and compliance record handed over at completion. These expectations are consistent with the requirements of insurers and mortgage lenders, one of the key motivations for developing PAS 8700 in the first place.

Integrating DfMA with BIM allows early clash detection, performance optimisation and collaboration across disciplines. Digital coordination also enables interoperability between platform components, reducing the need for bespoke design, and helping to maintain design integrity through manufacture and assembly.

Design teams are required to establish sustainability targets, including operational and embodied carbon, and to consider repair, replacement, adaptation and end-of-life recycling from the outset. For building services assemblies, this means selecting materials that can be disassembled, avoiding unnecessary use of composites that prevent recycling, and providing clear information on component weight, service life and replacement procedure.

PAS 8700 thereby complements CIBSE TM6511 and TM6612 on embodied carbon and circular economy principles. Increasingly, attention is also turning to whole-life cost and whole-life carbon metrics, moving project evaluation beyond capital expenditure. For public projects in particular, there is growing recognition of the social cost of carbon as part of investment decision-making.

Although PAS 8700 is formally limited to residential projects, many of its provisions are equally applicable to other sectors. Clause 6.2, which covers design life and replacement, and Clause 9.4, which addresses operational testing, both establish a discipline that benefits commercial and public buildings. The processes of early stakeholder engagement, design freeze, risk management and traceable testing can equally support, for example, prefabricated plant rooms, energy centres and district-heating substations in non-residential developments.

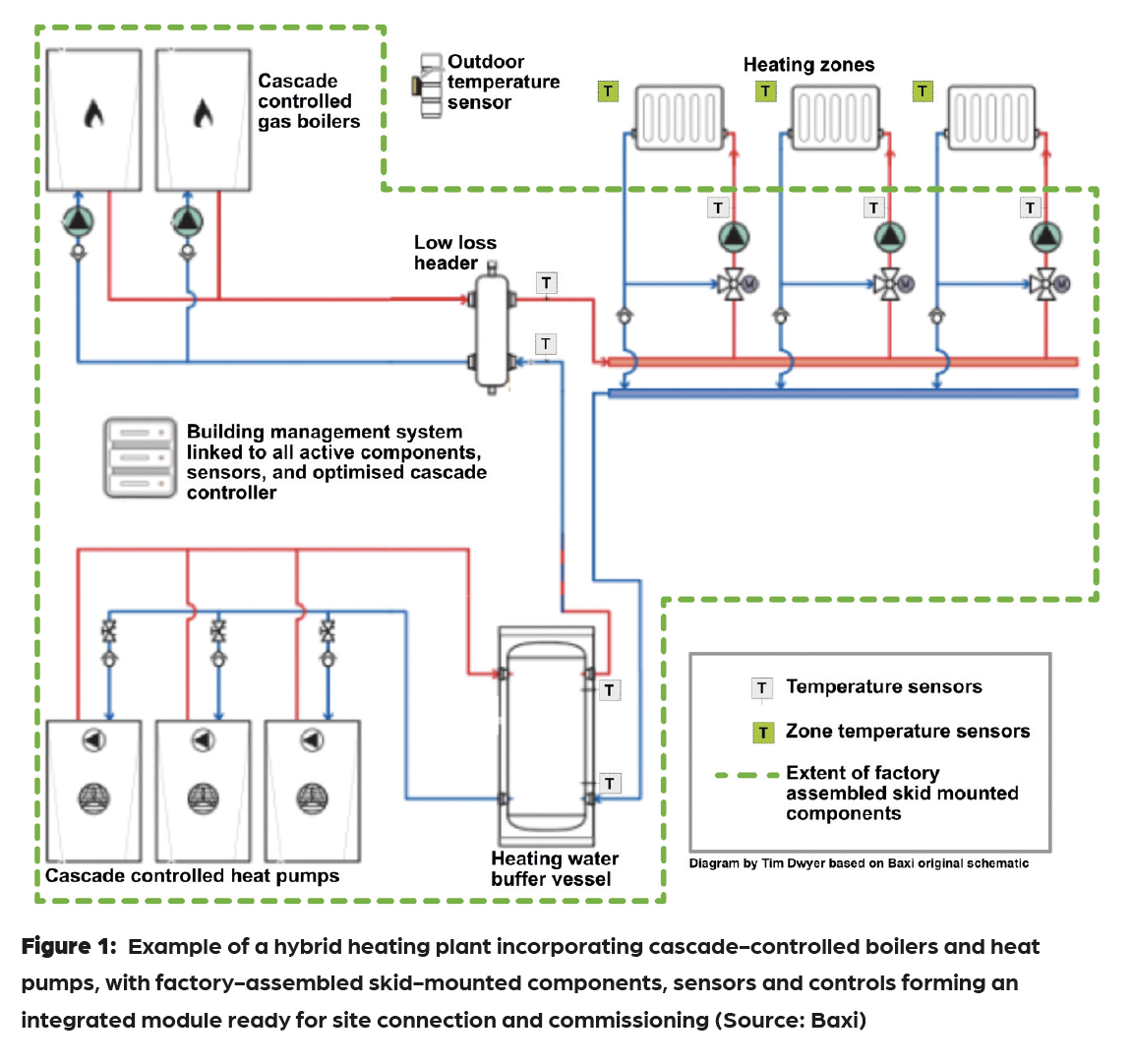

An illustrative example of factory assembly is given in Figure 1. The hybrid heating plant configuration combines cascade-controlled boilers and heat pumps serving multiple heating zones through a low-loss header and buffer vessel. Within the green dashed boundary, the entire skid-mounted assembly – which includes pumps, headers, valves, pipework, controls and temperature sensors – is prefabricated, wired and hydraulically tested in the factory. Each component is connected to the building management system (BMS) for coordinated control and monitoring.

The completed module is delivered to site as a pre-tested unit, craned into position, and connected to the distribution pipework and electrical supplies. This approach reduces on-site installation time, ensures consistent quality, and simplifies commissioning, with all test and inspection records forming part of the project’s digital quality file. It demonstrates how factory-built building services assemblies can satisfy the traceability, integration and competence requirements set out in PAS 8700.

A clear example of these techniques in non-residential projects is found in the NHS England Modern Methods of Construction Assessment Tool,13 published in 2025 to guide the design and delivery of healthcare buildings. The tool forms part of the NHS approach to embedding MMC, DfMA and platform construction within new and refurbished hospitals and clinics. It measures the pre-manufactured value of each project, identifying where factory-built components such as plantrooms, riser modules and service corridors can replace traditional on-site assembly.

The process links directly to NHS net zero and digital-build strategies, ensuring that prefabrication contributes to reduced embodied carbon, improved quality and faster programme delivery. Under the ProCure23 framework,14 teams use the assessment collaboratively to set measurable MMC targets and verify outcomes post-occupancy, providing a strong public sector example of how structured prefabrication and pre-manufactured value metrics are being used to deliver complex, safety-critical infrastructure within a regulated environment.

The earlier UK initiative known as platform design for manufacture and assembly (P-DfMA) sought to standardise repeatable building components so they could be configured across different project types. Its principles are now embedded within PAS 8700 and the wider MMC framework, promoting platform-based design and shared manufacturing supply chains.

The Construction Innovation Hub’s Product Platform Rulebook,15 developed with the Infrastructure and Projects Authority, expands this approach by providing practical guidance on creating repeatable building platforms with standardised structural grids, service interfaces and digital component libraries. While not mandatory, it is shaping government procurement policy and informs both the Construction Playbook16 and PAS 8700, making it a key reference for engineers applying platform-based MMC solutions.

The Construction Playbook, last updated in 2022 and still current as government guidance under the ‘comply or explain’ principle, remains a key policy document promoting value-based procurement, whole-life performance, and the adoption of MMC across public-sector projects. The Procurement Act 202317 updates the legal framework for public-sector contracting, but this not expected to replace the Construction Playbook. Instead, the Playbook’s principles of transparency, whole-life value and MMC will continue to guide how those statutory procurement duties are applied in practice.

The philosophy of factory-assembled construction is not unique to the UK. Hong Kong has advanced it through modular integrated construction (MiC) and modular integrated MEP (MiMEP) programmes18 led by the Construction Industry Council, while Singapore’s PPVC and similar frameworks in Europe and North America share the same DfMA principles.

Addressing the traditional bottleneck created by lengthy MEP installation remains one of the main motivations for modularisation. Applying DfMA to building services enables large portions of this work to move off-site, reducing programme risk and improving safety while maintaining assured performance through factory testing and standardised interfaces.

The benefits of factory assembly are realised not by moving the same work indoors but by transforming the process into one that is traceable, standardised and continuously improved. PAS 8700:2025 provides the UK’s formal specification for achieving these outcomes within the context of MMC, and offers a timely and authoritative framework that emphasises early integration, competence, quality assurance and life-cycle responsibility. It formalises many of the practices already adopted in advanced prefabrication projects.

For the building services community, the specification reinforces the case for modular and off-site manufacture as part of a disciplined, verifiable engineering process that supports the UK’s drive toward safer, lower-carbon and more productive buildings. When combined with the established guides and commissioning codes, it offers a structured route from design intent to assured performance – turning prefabrication from a convenient option into an accountable modern standard.

© Tim Dwyer 2025.

References:

1BSI PAS 8700:2025 Modern methods of construction for new-build residential properties, Specification, BSI, 2025 bit.ly/CJNov25CPD11.

2HM Government Modern Methods of Construction Framework – Seven Category Definitions, Ministry of Housing, Communities and Local Government, 2021.

3Building Safety Act 2022.

4CDM Regulations 2015.

5CIBSE Commissioning Code M Commissioning management, CIBSE 2022.

6BESA DW/144 Specification for sheet metal ductwork, BESA 2016.

7BESA DW/143 Guide to good practice: Ductwork leakage testing, BESA 2013.

8BESA DW/154 Specification for plastic ductwork, BESA 2013.

9BS 7593:2019 Code of practice for the preparation, commissioning and maintenance of domestic central heating and cooling water systems, BSI 2019.

10BS 7671:2022 Requirements for electrical installations (IET Wiring Regulations), BSI 2022.

11CIBSE TM65 Embodied carbon in building services engineering assessment, CIBSE 2021.

12CIBSE TM66 Circular economy assessment, CIBSE 2021.

13NHS England Modern Methods of Construction Assessment Tool: User Guide, NHS England, 2025, bit.ly/CJNov25CPD12 – accessed 6 October 2025.

14ProCure23: A new route to market for NHS capital works, NHS England – bit.ly/CJNov25CPD14

15Construction Innovation Hub The Product Platform Rulebook: Guidance on the development of shared manufacturing platforms for construction, Construction Innovation Hub and Infrastructure and Projects Authority, 2022.

16HM Government The Construction Playbook: Government guidance on sourcing and contracting public works projects and programmes (Version 1.1), Cabinet Office, 2022.

17HM Government Procurement Act 2023: Implementation guidance, Cabinet Office, 2024.

18Hong Kong Construction Industry Council Modular Integrated Construction (MiC) Design Guide, Hong Kong: CIC. 2019 – bit.ly/CJNov25CPD13.