Denmark has a target to reduce greenhouse gas emissions by 70% by 2030 and a goal of climate neutrality by 2050. Fundamental to achieving this is the transition of the Danish heating sector to near-zero CO2 emissions by 2030.

To assess how the heat sector can transform in a technically, economically and environmentally appropriate way in such a short period of time, researchers at the University of Aalborg (AAU) developed the Heat Plan Denmark 2021. This document sets out how the heating sector can transform relatively quickly using technologies that are already available. See panel, ‘Heat Plan Denmark: key messages’.

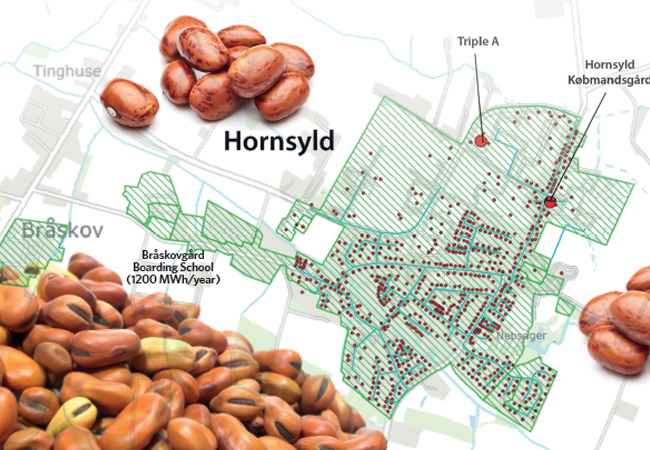

The Hornsyld Project is a good example of how Hornsyld-Bråskov local council is planning to apply the Heat Plan Denmark 2021 by using heat from industrial processes – specifically from drying beans used for animal feeds –to transform the heat supply for Hornsyld’s 1,600 inhabitants, as well as schools, sports facilities and businesses.

Hornsyld is a compact town with a relatively high density of heat-consuming buildings, with a peak heat load of 5.3MW. Currently, the majority of its dwellings and businesses are heated by individual natural gas boilers.

The local council is proposing to install a new district heating system to use the large amount of heat being lost to the atmosphere by Hornsyld’s industries. The two main industries in the town are Triple A, an animal feed producer, and Hornsyld Købmandsgård, a grocer and agro-business that grows horse beans (a member of the broad bean family) for use in animal feed. The waste heat for the scheme will come from a feed dryer at Triple A.

The drying process uses air heated directly by the combustion of natural gas. This air is drawn through the feed, which evaporates approximately 6,000 litres of water an hour. Currently, the hot and humid exhaust air is discharged to the atmosphere at a temperature of approximately 60°C.

Under the council’s proposal, a scrubber will be used to wash the exhaust air with cold water to condense the vapour from the air stream. A heat pump will extract heat from the warmed condensate and then raise its temperature to the outlet temperature for the district heating supply.

The process is expected to produce between 4MW and 5MW of heat. However, only 3MW will be used for this project, consisting of 2MW supplied by the heat pump and an additional 1MW from direct exchange. The feed dryer is expected to run for a minimum of 7,500 hours per year. Heat production is calculated to give a system coefficient of performance (COP) of 6.75.

Two boilers at Hornsyld Købmandsgård will be used to supplement the reclaimed heat from Triple A. One is a 1.8MW unit fuelled by biomass – which is primarily waste material from grain products – and the heat is mainly used for process heating for Triple A. When production is under way at Triple A, only 0.9MW of capacity will be available from the biomass boiler.

The boiler is also used to produce heat for Hornsyld School, Hornsyld Købmandsgård, and a few other nearby buildings, all of which are expected to be included in the district heating system, so this element of boiler capacity will be available to the network.

The other Hornsyld Købmandsgård boiler is a 4MW oil-fired boiler. This will be converted to run on natural gas, and will serve as a back-up to the biomass boiler. It is assumed that 3.5MW of capacity will be available for the district heating supply. The operational and maintenance costs of both boilers will be covered under the scheme.

Waste grain products will provide fuel for a 1.8MW biomass boiler

To provide a buffer between the heat demand, production at Triple A, and the operation of the boilers, the system will incorporate a 1,000m3 thermal store. The addition of a storage tank will allow greater use of the available waste heat and the biomass boiler.

There is currently no heat network in Hornsyld, so a new plantroom will be constructed. Heat will be distributed via a pre-insulated, twin-pipe system.

Planenergi, the consulting engineers responsible for the project, are continuously updating the project as certainty increases around customers numbers, and energy costs rise. SAV Systems are PlanEnergi’s design partner in

the UK.

Anchor loads

Of the 471 buildings supplied by natural gas in Hornsyld, there are 29 large heat consumers, with an annual heat demand of more than 100MWh. Together, they could amount to a heat demand of more than 9,000MWh annually, which will provide sufficient anchor loads for the heat network. The council hopes that a high connection rate can be achieved by signing up these large consumers so that the project is less dependent on getting a high take-up from large numbers of domestic customers.

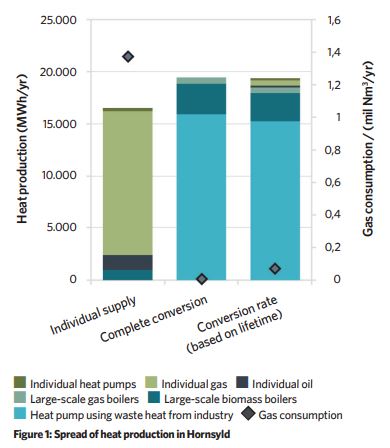

The heat network is designed to supply 100% of Hornsyld’s heat demand. However, the project has assumed a total connection rate corresponding to 60% of the heating demand, and it is expected to be converted at the rate indicated in Figure 1. A total annual heat loss of 15.2% has also been calculated for the network, corresponding to 2,942MWh/year. This gives a total heat requirement of 19,395MWh/year.

Cost savings

The project is expected to provide an annual cost saving of 6,300 Danish kroner (DKK – about £700) for a typical dwelling currently heated by natural gas, and DKK 5,400 (about £600) for one heated by an air-to-water heat pump. The savings are well above the minimum set by the Danish Project Evaluation Act, which requires a cost saving of £170 per household for a project to be approved.

An estimated socio-economic surplus of £4.1m has been identified for the project over 20 years, largely because of the reduction in natural gas consumption, which more than offsets the investment cost

Heat plan Denmark 2021: key messages

The heating sector can be transformed quickly using available technologies – the four key messages are:

- Energy savings of between 36-40% are required in the current building stock to cost-effectively minimise the demand for heat.

- District heating should be expanded to supply up to 70% of building heat demand, to enable individual building’s gas- and oil-fired boilers to be taken out of commission.

- Existing third-generation heat networks should be transitioned to lower-temperature, fourth-generation networks, to enable low-grade waste and geothermal heat to be used efficiently.

- Waste heat and geothermal heat should be exploited to provide up to half of the heat demand from district heating systems in the energy system of the future.