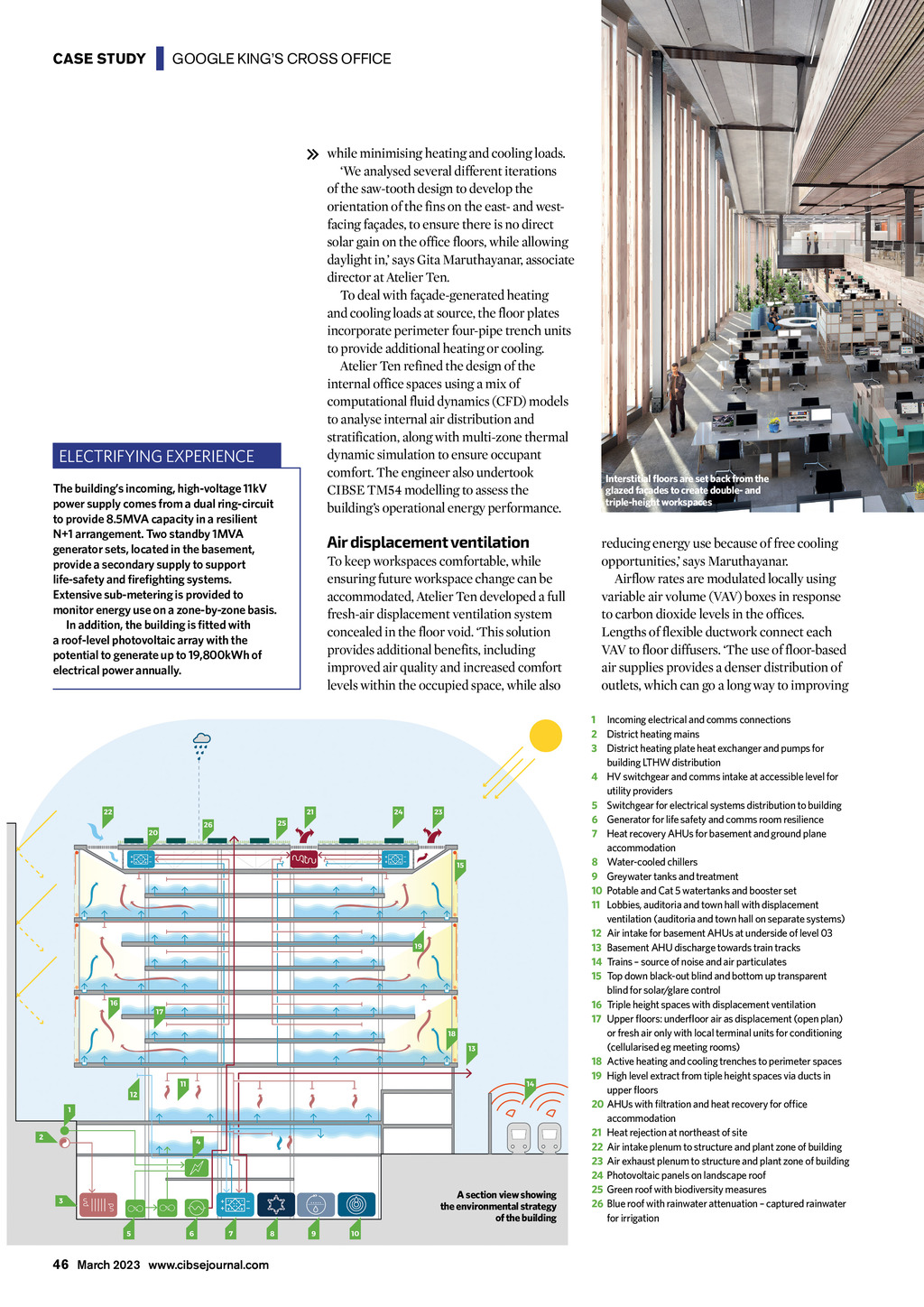

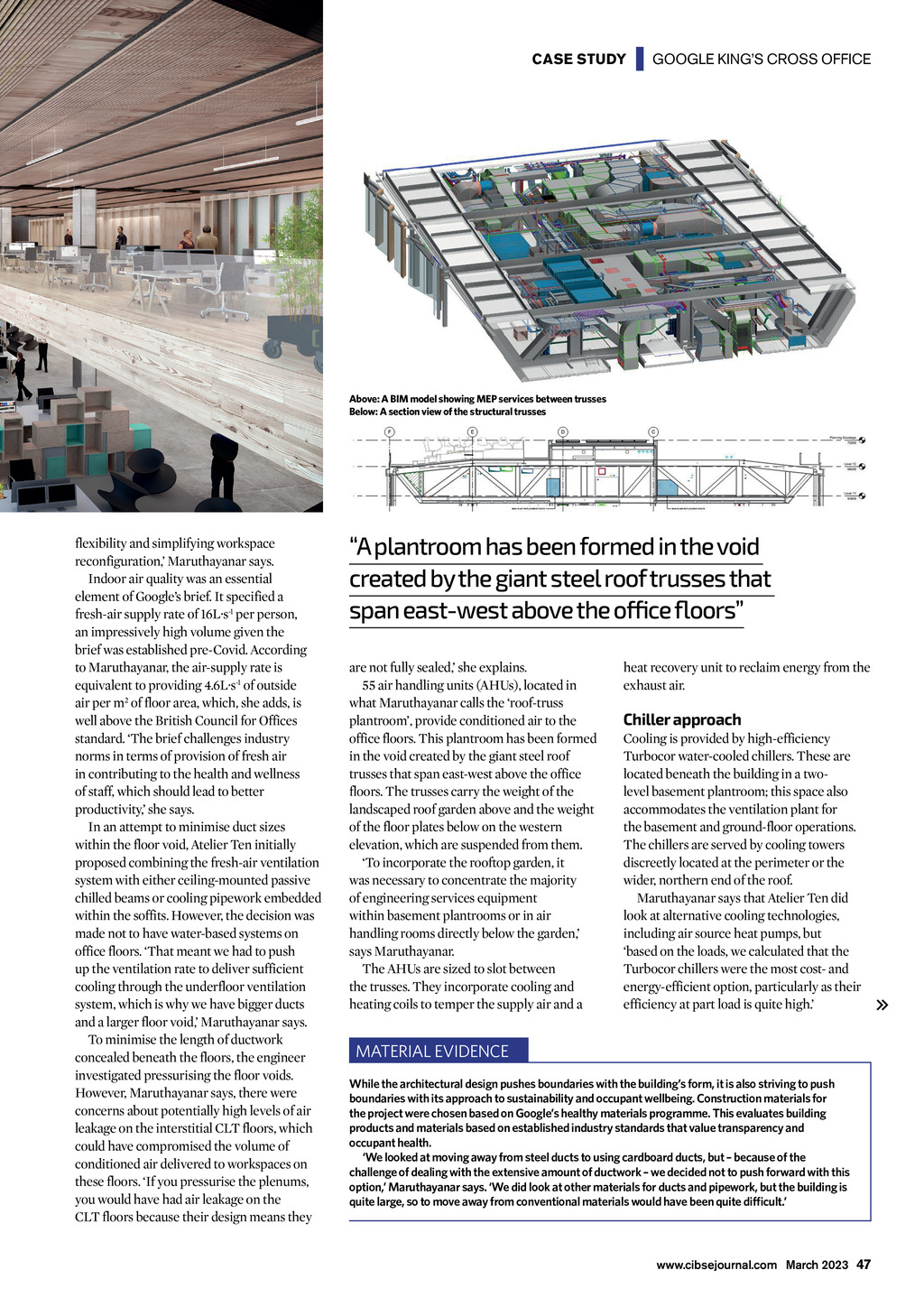

CASE STUDY | GOOGLE KINGS CROSS OFFICE ELECTRIFYING EXPERIENCE The buildings incoming, high-voltage 11kV power supply comes from a dual ring-circuit to provide 8.5MVA capacity in a resilient N+1 arrangement. Two standby 1MVA generator sets, located in the basement, provide a secondary supply to support life-safety and firefighting systems. Extensive sub-metering is provided to monitor energy use on a zone-by-zone basis. In addition, the building is fitted with a roof-level photovoltaic array with the potential to generate up to 19,800kWh of electrical power annually. while minimising heating and cooling loads. We analysed several different iterations of the saw-tooth design to develop the orientation of the fins on the east- and westfacing faades, to ensure there is no direct solar gain on the office floors, while allowing daylight in, says Gita Maruthayanar, associate director at Atelier Ten. To deal with faade-generated heating and cooling loads at source, the floor plates incorporate perimeter four-pipe trench units to provide additional heating or cooling. Atelier Ten refined the design of the internal office spaces using a mix of computational fluid dynamics (CFD) models to analyse internal air distribution and stratification, along with multi-zone thermal dynamic simulation to ensure occupant comfort. The engineer also undertook CIBSE TM54 modelling to assess the buildings operational energy performance. Air displacement ventilation To keep workspaces comfortable, while ensuring future workspace change can be accommodated, Atelier Ten developed a full fresh-air displacement ventilation system concealed in the floor void. This solution provides additional benefits, including improved air quality and increased comfort levels within the occupied space, while also A section view showing the environmental strategy of the building 46 March 2023 www.cibsejournal.com Interstitial floors are set back from the glazed faades to create double- and triple-height workspaces reducing energy use because of free cooling opportunities, says Maruthayanar. Airflow rates are modulated locally using variable air volume (VAV) boxes in response to carbon dioxide levels in the offices. Lengths of flexible ductwork connect each VAV to floor diffusers. The use of floor-based air supplies provides a denser distribution of outlets, which can go a long way to improving 1 Incoming electrical and comms connections 2 District heating mains 3 District heating plate heat exchanger and pumps for building LTHW distribution 4 HV switchgear and comms intake at accessible level for utility providers 5 Switchgear for electrical systems distribution to building 6 Generator for life safety and comms room resilience 7 Heat recovery AHUs for basement and ground plane accommodation 8 Water-cooled chillers 9 Greywater tanks and treatment 10 Potable and Cat 5 watertanks and booster set 11 Lobbies, auditoria and town hall with displacement ventilation (auditoria and town hall on separate systems) 12 Air intake for basement AHUs at underside of level 03 13 Basement AHU discharge towards train tracks 14 Trains source of noise and air particulates 15 Top down black-out blind and bottom up transparent blind for solar/glare control 16 Triple height spaces with displacement ventilation 17 Upper floors: underfloor air as displacement (open plan) or fresh air only with local terminal units for conditioning (cellularised eg meeting rooms) 18 Active heating and cooling trenches to perimeter spaces 19 High level extract from tiple height spaces via ducts in upper floors 20 AHUs with filtration and heat recovery for office accommodation 21 Heat rejection at northeast of site 22 Air intake plenum to structure and plant zone of building 23 Air exhaust plenum to structure and plant zone of building 24 Photovoltaic panels on landscape roof 25 Green roof with biodiversity measures 26 Blue roof with rainwater attenuation captured rainwater for irrigation