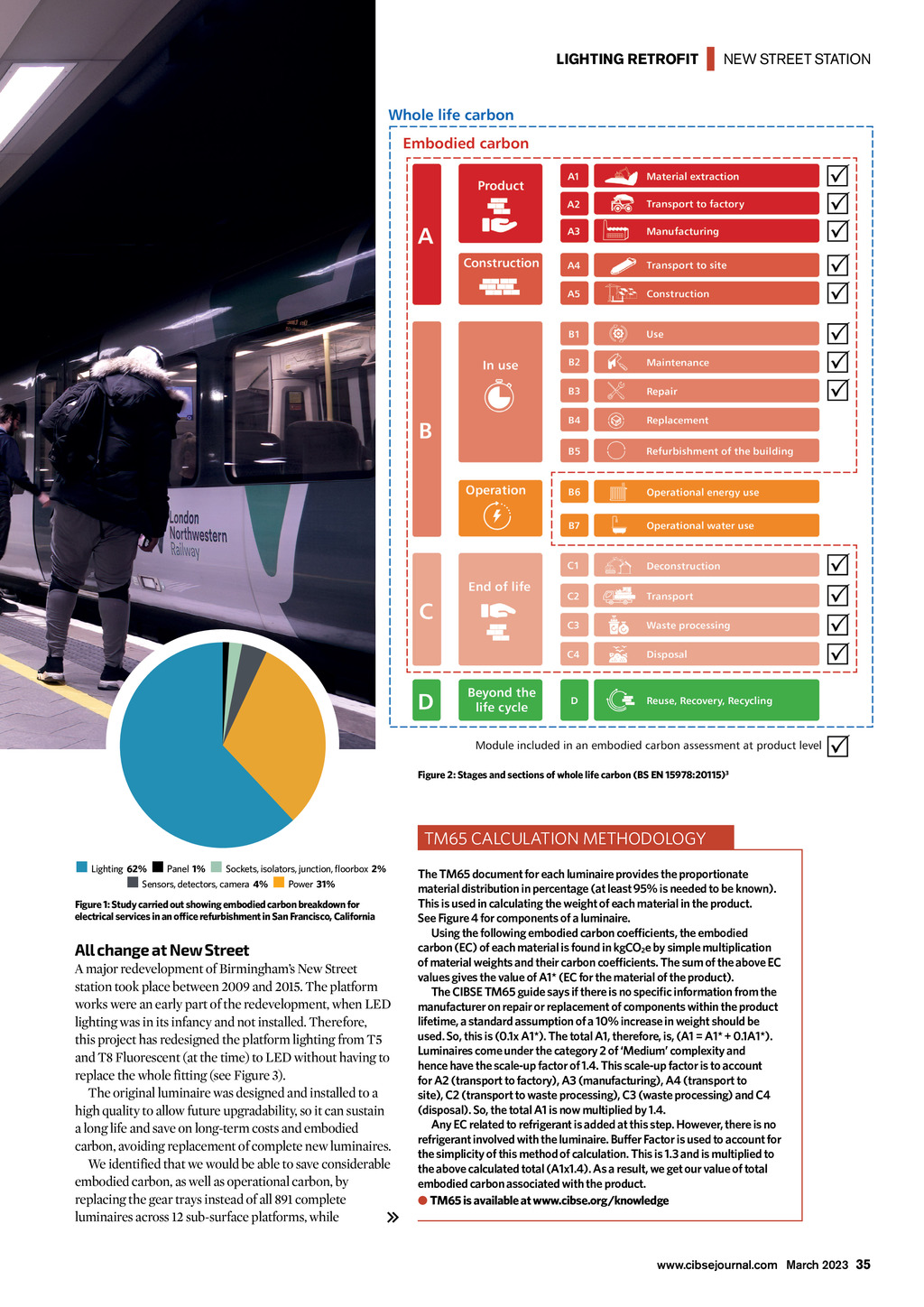

LIGHTING RETROFIT | NEW STREET STATION CIRCULAR ROUTE To minimise embodied carbon in the retrofitting of nearly 900 luminaires at Birminghams New Street station, Q Sustain used CIBSE TM65 to calculate the potential savings of reusing existing luminaires. The firms Lovely Chavan and Yara Bekdache explain how it saved more than 163 tonnes of embodied carbon T he construction industry has long focused on operational carbon, but has not often considered emissions related to the other life-cycle stages of building services products and equipment. As much as half of the life-cycle carbon emissions from buildings comes from embodied sources, such as manufacturing of materials and construction processes. In retrofits, building services accounts for 40-70% of embodied carbon emissions and 15-20% in new build. In the electrical category, LED lighting makes up the highest proportion of embodied emissions1. To make well-informed decisions, engineers and designers need to embrace whole life embodied carbon emissions and educate the client. Whole life carbon assessment has five main components and is divided into A, B, C and D sections, as explained in Figure 2. It is the carbon emitted in the whole life-cycle of a component. Embodied carbon does not incorporate the carbon in the operations and beyond life-cycle categories. In a recent refurbishment scheme at New Street station in Birmingham, Network Rail along with its sustainability consultant Q Sustain aimed to minimise the embodied carbon emissions resulting from the replacement of fluorescent lighting with LEDs on 12 platforms. This was the first time that the minimisation of embodied carbon was made a key requirement by Network Rail in an enhancement and renewal scheme. 34 March 2023 www.cibsejournal.com Q Sustain calculated the embodied energy savings of reusing luminaires and replacing the gear trays the container that holds the electrical components protecting them from dust and moisture. The project team calculated that 163 tonnes of embodied CO2e would be saved. The reduction in operational carbon as a result of using LEDs was also significant, with an estimated 67 tonnes of CO2e saved every year. Calculations for embodied energy were based on the calculation methodology in TM65 Embodied carbon in building services2. It assesses the embodied carbon across the whole life-cycle of the product, which includes raw materials extraction, manufacturing, repair and disposal. This method focuses on the embodied carbon of a product rather than a system or a building. This is based on information provided within an Environmental Product Declaration (EPD); however, such documents and information are not always available from suppliers. At New Street, data supplied by Designplan Lighting, the manufacturers of the upgradeable flair luminaire, enabled the project team to calculate the savings in embodied carbon (kgCO2e). It provided information relating to the products weight per material type and service life, as well as a breakdown of all the components, with their production location and energy use.