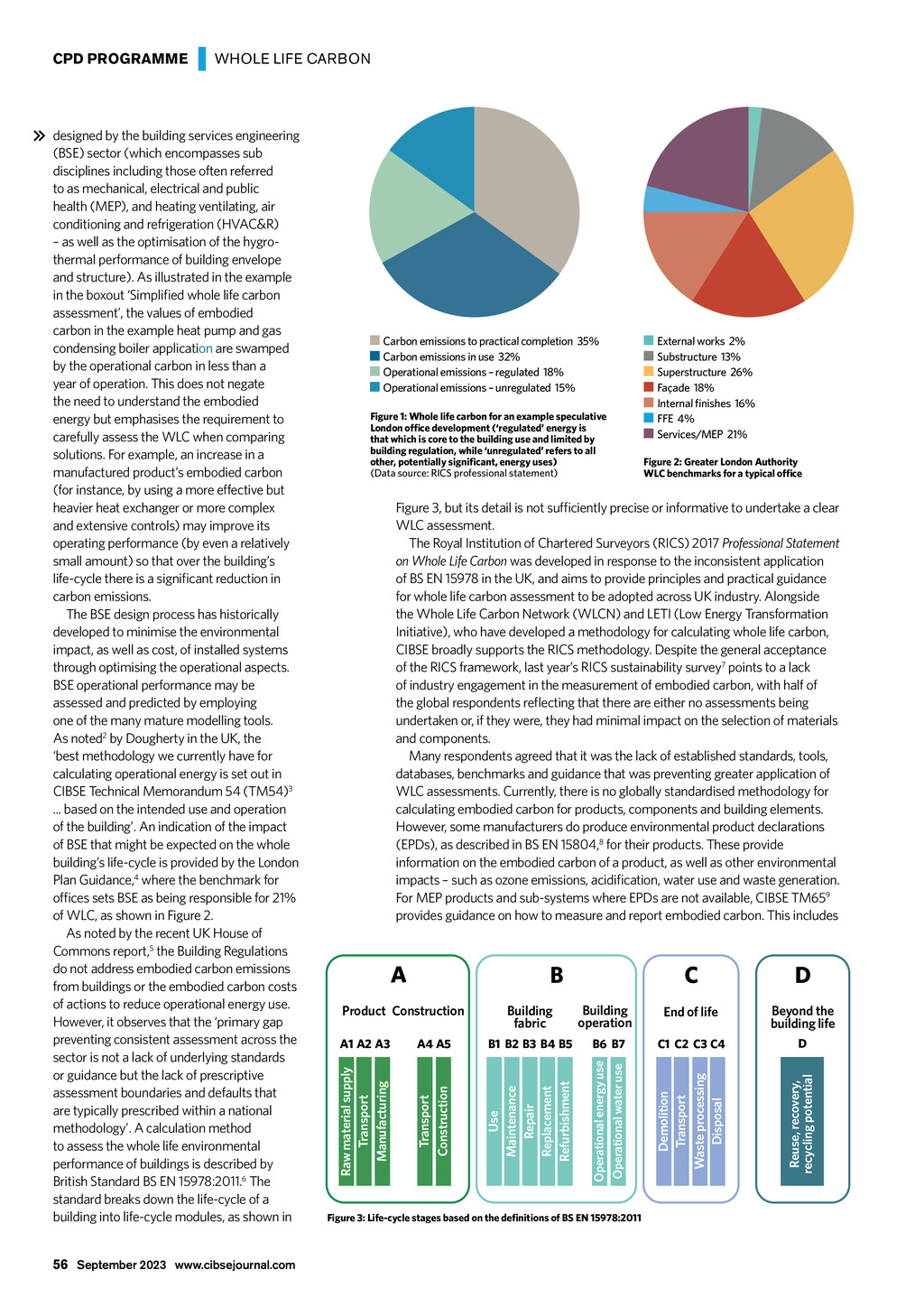

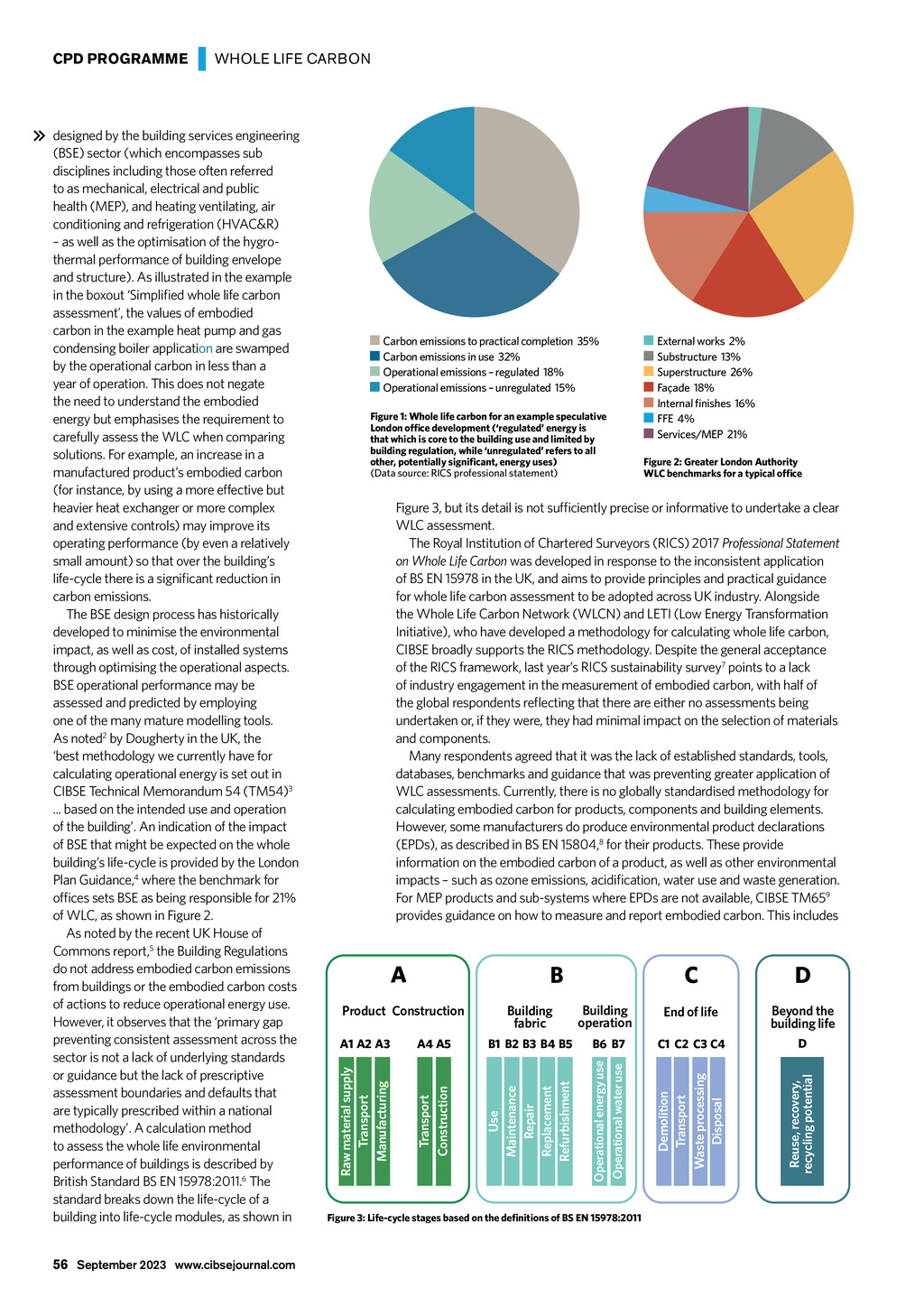

| WHOLE LIFE CARBON 56 September 2023 www.cibsejournal.com Carbon emissions to practical completion 35% Carbon emissions in use 32% Operational emissions regulated 18% Operational emissions unregulated 15% Figure 1: Whole life carbon for an example speculative London office development (regulated energy is that which is core to the building use and limited by building regulation, while unregulated refers to all other, potentially significant, energy uses) (Data source: RICS professional statement) External works 2% Substructure 13% Superstructure 26% Faade 18% Internal finishes 16% FFE 4% Services/MEP 21% Figure 2: Greater London Authority WLC benchmarks for a typical office Figure 3, but its detail is not sufficiently precise or informative to undertake a clear WLC assessment. The Royal Institution of Chartered Surveyors (RICS) 2017 Professional Statement on Whole Life Carbon was developed in response to the inconsistent application of BS EN 15978 in the UK, and aims to provide principles and practical guidance for whole life carbon assessment to be adopted across UK industry. Alongside the Whole Life Carbon Network (WLCN) and LETI (Low Energy Transformation Initiative), who have developed a methodology for calculating whole life carbon, CIBSE broadly supports the RICS methodology. Despite the general acceptance of the RICS framework, last years RICS sustainability survey7 points to a lack of industry engagement in the measurement of embodied carbon, with half of the global respondents reflecting that there are either no assessments being undertaken or, if they were, they had minimal impact on the selection of materials and components. Many respondents agreed that it was the lack of established standards, tools, databases, benchmarks and guidance that was preventing greater application of WLC assessments. Currently, there is no globally standardised methodology for calculating embodied carbon for products, components and building elements. However, some manufacturers do produce environmental product declarations (EPDs), as described in BS EN 15804,8 for their products. These provide information on the embodied carbon of a product, as well as other environmental impacts such as ozone emissions, acidification, water use and waste generation. For MEP products and sub-systems where EPDs are not available, CIBSE TM659 provides guidance on how to measure and report embodied carbon. This includes A B Beyond the building life A1 A2 A3 A4 A5 B1 B2 B3 B4 B5 B6 B7 C1 C2 C3 C4 D Reuse, recovery, recycling potential End of life Demolition Transport Waste processing Disposal Building operation Operational energy use Operational water use Building fabric D Use Maintenance Repair Replacement Refurbishment Product Construction C Transport Construction designed by the building services engineering (BSE) sector (which encompasses sub disciplines including those often referred to as mechanical, electrical and public health (MEP), and heating ventilating, air conditioning and refrigeration (HVAC&R) as well as the optimisation of the hygrothermal performance of building envelope and structure). As illustrated in the example in the boxout Simplified whole life carbon assessment, the values of embodied carbon in the example heat pump and gas condensing boiler application are swamped by the operational carbon in less than a year of operation. This does not negate the need to understand the embodied energy but emphasises the requirement to carefully assess the WLC when comparing solutions. For example, an increase in a manufactured products embodied carbon (for instance, by using a more effective but heavier heat exchanger or more complex and extensive controls) may improve its operating performance (by even a relatively small amount) so that over the buildings life-cycle there is a significant reduction in carbon emissions. The BSE design process has historically developed to minimise the environmental impact, as well as cost, of installed systems through optimising the operational aspects. BSE operational performance may be assessed and predicted by employing one of the many mature modelling tools. As noted2 by Dougherty in the UK, the best methodology we currently have for calculating operational energy is set out in CIBSE Technical Memorandum 54 (TM54)3 ... based on the intended use and operation of the building. An indication of the impact of BSE that might be expected on the whole buildings life-cycle is provided by the London Plan Guidance,4 where the benchmark for offices sets BSE as being responsible for 21% of WLC, as shown in Figure 2. As noted by the recent UK House of Commons report,5 the Building Regulations do not address embodied carbon emissions from buildings or the embodied carbon costs of actions to reduce operational energy use. However, it observes that the primary gap preventing consistent assessment across the sector is not a lack of underlying standards or guidance but the lack of prescriptive assessment boundaries and defaults that are typically prescribed within a national methodology. A calculation method to assess the whole life environmental performance of buildings is described by British Standard BS EN 15978:2011.6 The standard breaks down the life-cycle of a building into life-cycle modules, as shown in Raw material supply Transport Manufacturing CPD PROGRAMME Figure 3: Life-cycle stages based on the definitions of BS EN 15978:2011