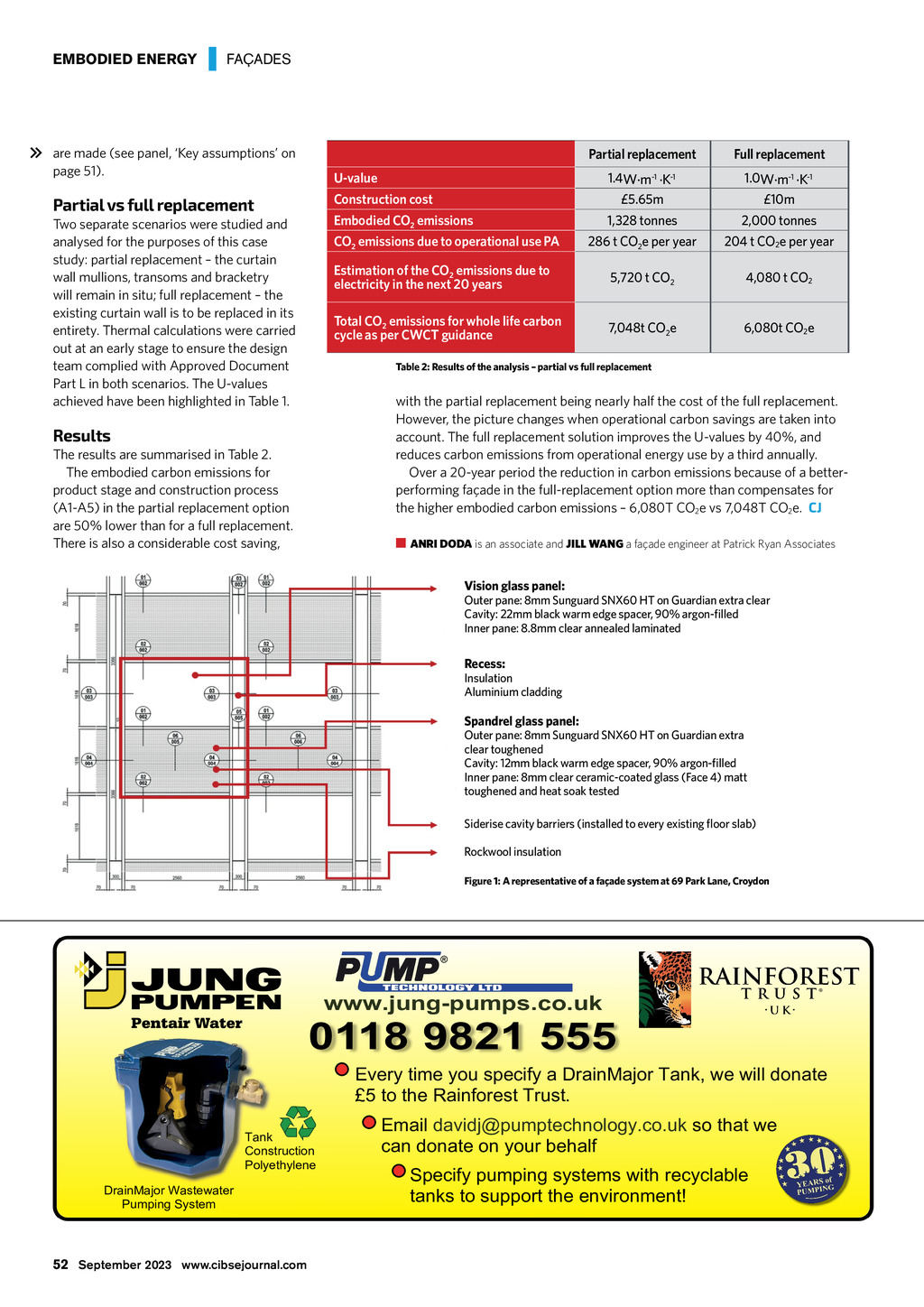

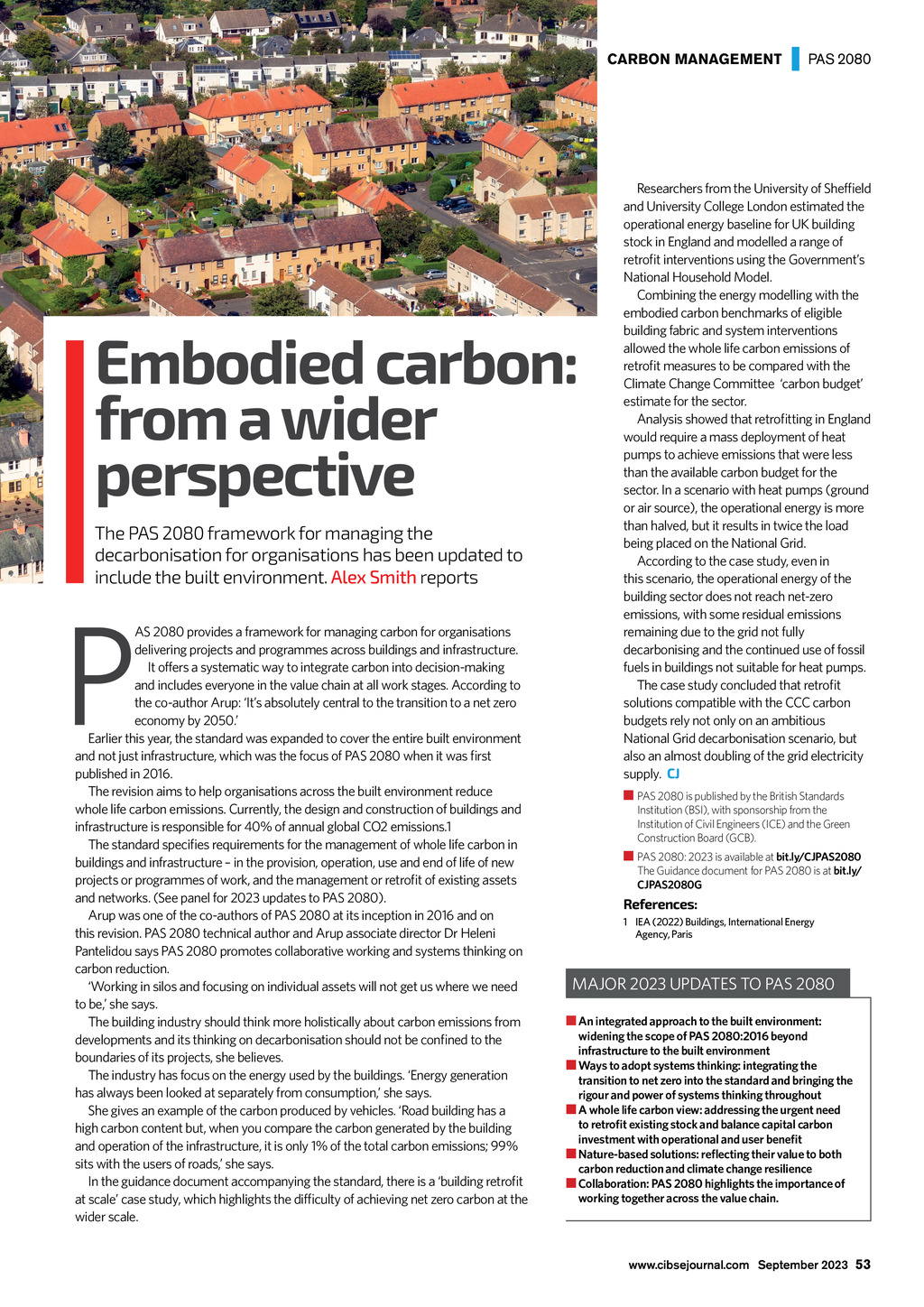

EMBODIED ENERGY | FAADES are made (see panel, Key assumptions on page 51). Partial replacement Full replacement 1.4Wm K 5.65m 1.0Wm-1 K-1 10m U-value -1 Construction cost Partial vs full replacement Embodied CO2 emissions Two separate scenarios were studied and analysed for the purposes of this case study: partial replacement the curtain wall mullions, transoms and bracketry will remain in situ; full replacement the existing curtain wall is to be replaced in its entirety. Thermal calculations were carried out at an early stage to ensure the design team complied with Approved Document Part L in both scenarios. The U-values achieved have been highlighted in Table 1. -1 1,328 tonnes 2,000 tonnes 286 t CO2e per year 204 t CO2e per year Estimation of the CO2 emissions due to electricity in the next 20 years 5,720 t CO2 4,080 t CO2 Total CO2 emissions for whole life carbon cycle as per CWCT guidance 7,048t CO2e 6,080t CO2e CO2 emissions due to operational use PA Table 2: Results of the analysis partial vs full replacement with the partial replacement being nearly half the cost of the full replacement. However, the picture changes when operational carbon savings are taken into account. The full replacement solution improves the U-values by 40%, and reduces carbon emissions from operational energy use by a third annually. Over a 20-year period the reduction in carbon emissions because of a betterperforming faade in the full-replacement option more than compensates for the higher embodied carbon emissions 6,080T CO2e vs 7,048T CO2e. CJ Results The results are summarised in Table 2. The embodied carbon emissions for product stage and construction process (A1-A5) in the partial replacement option are 50% lower than for a full replacement. There is also a considerable cost saving, ANRI DODA is an associate and JILL WANG a faade engineer at Patrick Ryan Associates Vision glass panel: Outer pane: 8mm Sunguard SNX60 HT on Guardian extra clear Cavity: 22mm black warm edge spacer, 90% argon-filled Inner pane: 8.8mm clear annealed laminated Recess: Insulation Aluminium cladding Spandrel glass panel: Outer pane: 8mm Sunguard SNX60 HT on Guardian extra clear toughened Cavity: 12mm black warm edge spacer, 90% argon-filled Inner pane: 8mm clear ceramic-coated glass (Face 4) matt toughened and heat soak tested Siderise cavity barriers (installed to every existing floor slab) Rockwool insulation Figure 1: A representative of a faade system at 69 Park Lane, Croydon www.jung-pumps.co.uk 0118 9821 555 Every time you specify a DrainMajor Tank, we will donate 5 to the Rainforest Trust. Tank Construction Polyethylene DrainMajor Wastewater Pumping System 52 September 2023 www.cibsejournal.com Email davidj@pumptechnology.co.uk so that we can donate on your behalf Specify pumping systems with recyclable tanks to support the environment!