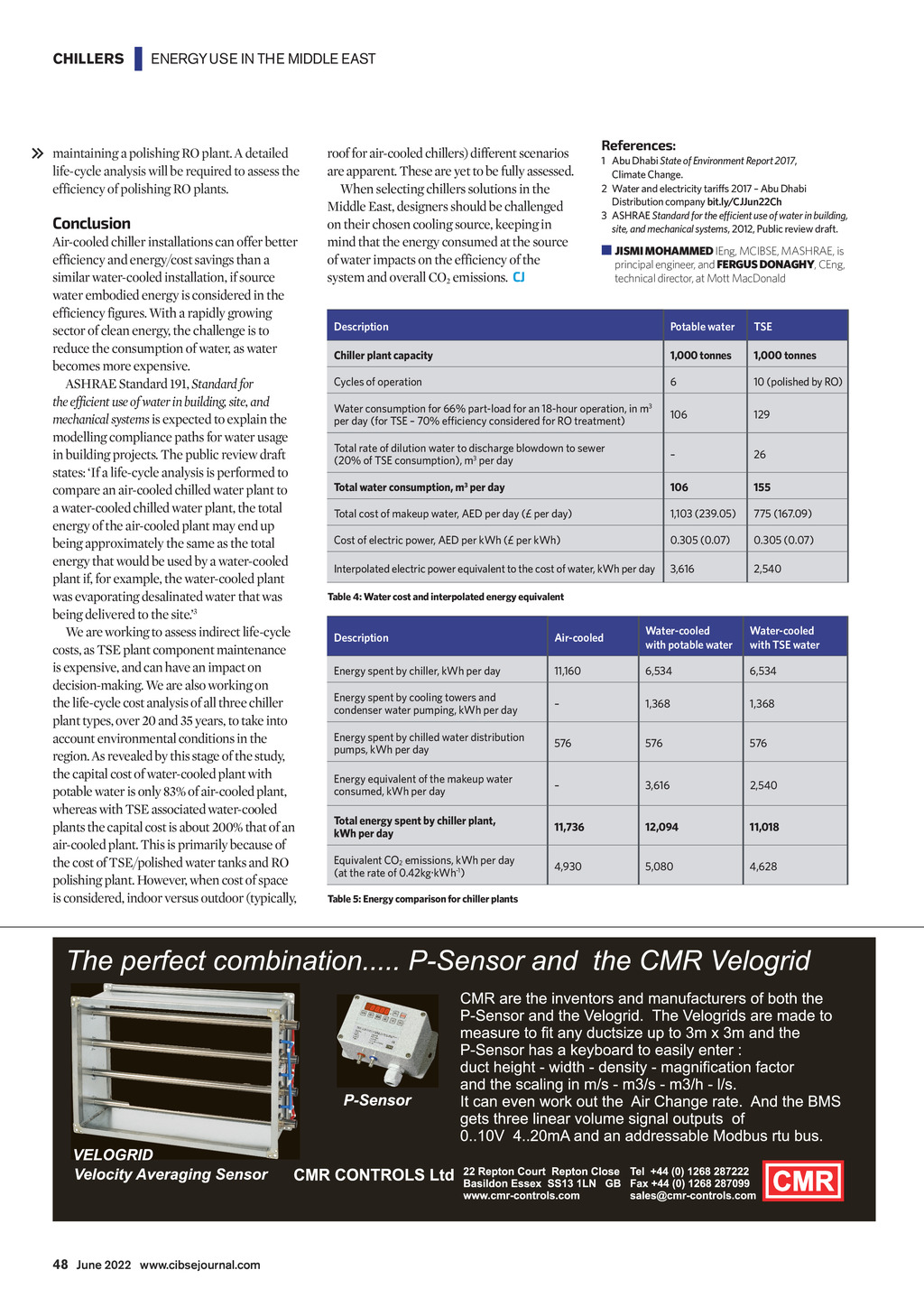

CHILLERS | ENERGY USE IN THE MIDDLE EAST maintaining a polishing RO plant. A detailed life-cycle analysis will be required to assess the efficiency of polishing RO plants. Conclusion Air-cooled chiller installations can offer better efficiency and energy/cost savings than a similar water-cooled installation, if source water embodied energy is considered in the efficiency figures. With a rapidly growing sector of clean energy, the challenge is to reduce the consumption of water, as water becomes more expensive. ASHRAE Standard 191, Standard for the efficient use of water in building, site, and mechanical systems is expected to explain the modelling compliance paths for water usage in building projects. The public review draft states: If a life-cycle analysis is performed to compare an air-cooled chilled water plant to a water-cooled chilled water plant, the total energy of the air-cooled plant may end up being approximately the same as the total energy that would be used by a water-cooled plant if, for example, the water-cooled plant was evaporating desalinated water that was being delivered to the site.3 We are working to assess indirect life-cycle costs, as TSE plant component maintenance is expensive, and can have an impact on decision-making. We are also working on the life-cycle cost analysis of all three chiller plant types, over 20 and 35 years, to take into account environmental conditions in the region. As revealed by this stage of the study, the capital cost of water-cooled plant with potable water is only 83% of air-cooled plant, whereas with TSE associated water-cooled plants the capital cost is about 200% that of an air-cooled plant. This is primarily because of the cost of TSE/polished water tanks and RO polishing plant. However, when cost of space is considered, indoor versus outdoor (typically, roof for air-cooled chillers) different scenarios are apparent. These are yet to be fully assessed. When selecting chillers solutions in the Middle East, designers should be challenged on their chosen cooling source, keeping in mind that the energy consumed at the source of water impacts on the efficiency of the system and overall CO2 emissions. CJ References: 1 Abu Dhabi State of Environment Report 2017, Climate Change. 2 Water and electricity tariffs 2017 Abu Dhabi Distribution company bit.ly/CJJun22Ch 3 ASHRAE Standard for the efficient use of water in building, site, and mechanical systems, 2012, Public review draft. JISMI MOHAMMED IEng, MCIBSE, MASHRAE, is principal engineer, and FERGUS DONAGHY, CEng, technical director, at Mott MacDonald Description Potable water TSE Chiller plant capacity 1,000 tonnes 1,000 tonnes Cycles of operation 6 10 (polished by RO) Water consumption for 66% part-load for an 18-hour operation, in m3 per day (for TSE 70% efficiency considered for RO treatment) 106 129 Total rate of dilution water to discharge blowdown to sewer (20% of TSE consumption), m3 per day 26 Total water consumption, m3 per day 106 155 Total cost of makeup water, AED per day ( per day) 1,103 (239.05) 775 (167.09) Cost of electric power, AED per kWh ( per kWh) 0.305 (0.07) 0.305 (0.07) Interpolated electric power equivalent to the cost of water, kWh per day 3,616 2,540 Table 4: Water cost and interpolated energy equivalent Description Air-cooled Water-cooled with potable water Water-cooled with TSE water Energy spent by chiller, kWh per day 11,160 6,534 6,534 Energy spent by cooling towers and condenser water pumping, kWh per day 1,368 1,368 Energy spent by chilled water distribution pumps, kWh per day 576 576 576 Energy equivalent of the makeup water consumed, kWh per day 3,616 2,540 Total energy spent by chiller plant, kWh per day 11,736 12,094 11,018 Equivalent CO2 emissions, kWh per day (at the rate of 0.42kg.kWh-1) 4,930 5,080 4,628 Table 5: Energy comparison for chiller plants 48 June 2022 www.cibsejournal.com CIBSE June 22 pp46-48 Chiller in Middle East.indd 48 27/05/2022 15:38