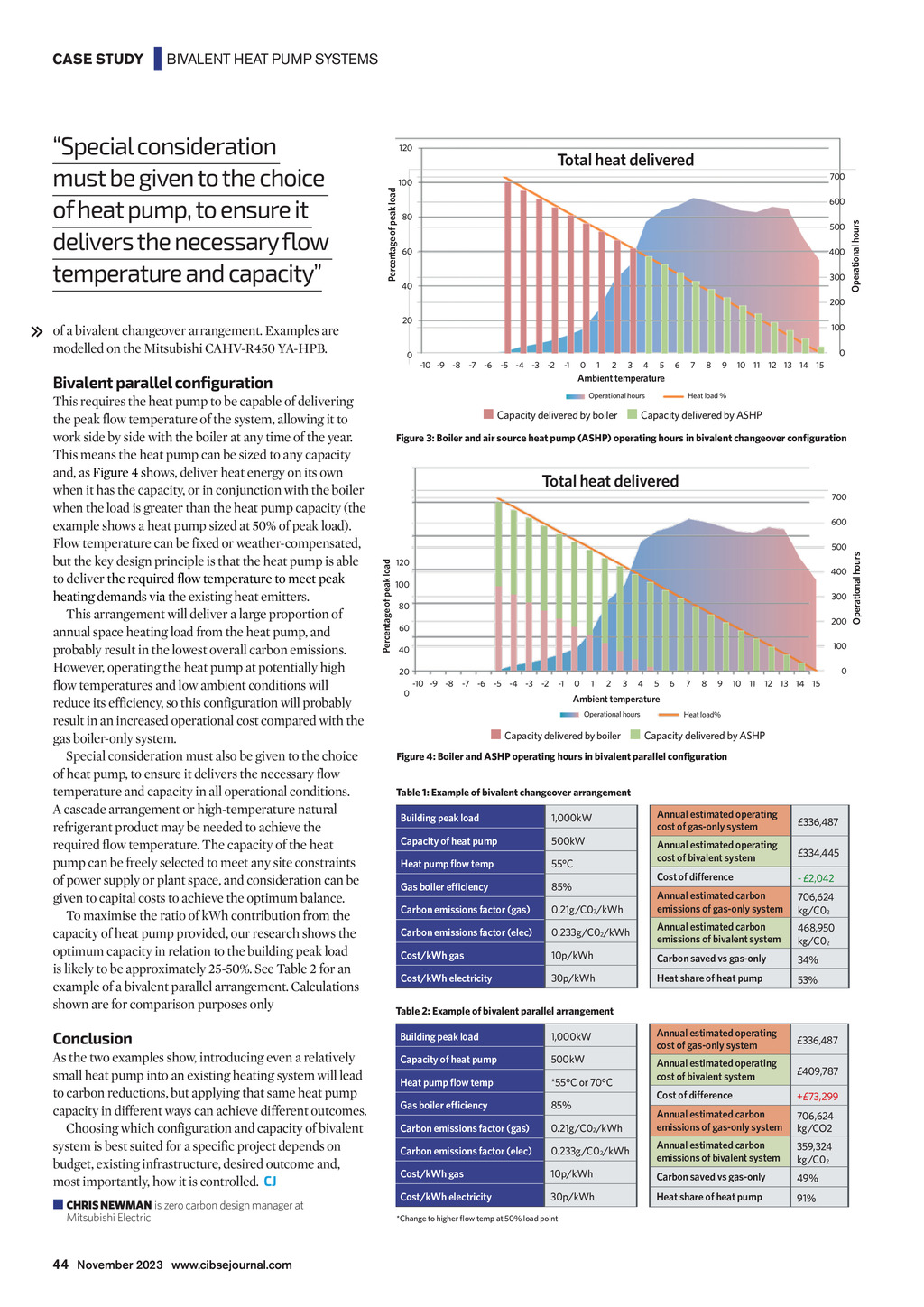

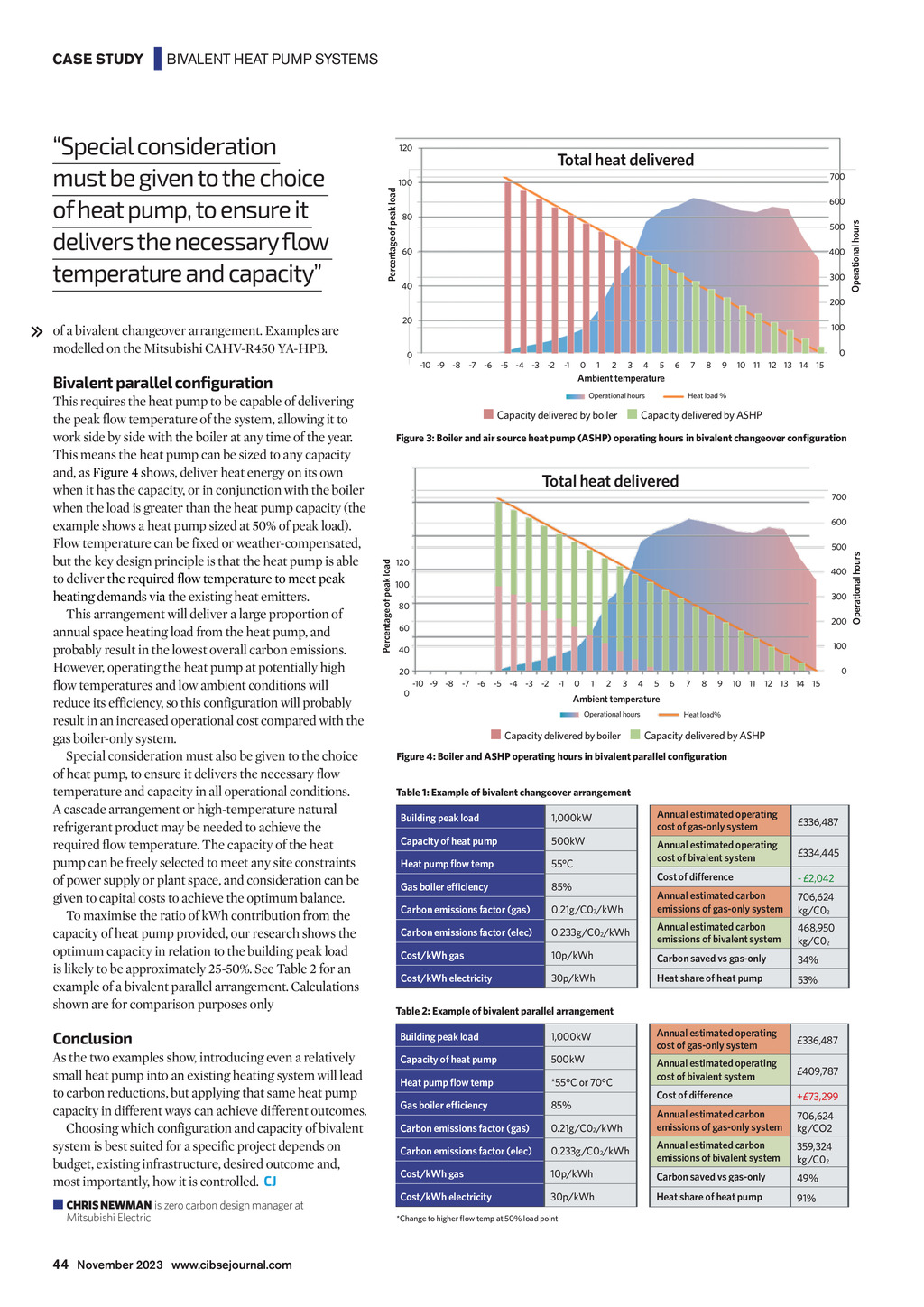

| BIVALENT HEAT PUMP SYSTEMS 120 Total heat delivered 700 100 600 80 500 60 400 300 40 Operational hours Special consideration must be given to the choice of heat pump, to ensure it delivers the necessary flow temperature and capacity Percentage of peak load CASE STUDY 200 20 of a bivalent changeover arrangement. Examples are modelled on the Mitsubishi CAHV-R450 YA-HPB. 0 100 0 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Ambient temperature Bivalent parallel configuration Operational hours Heat load % Capacity delivered by boiler Capacity delivered by ASHP Figure 3: Boiler and air source heat pump (ASHP) operating hours in bivalent changeover configuration Total heat delivered 700 600 120 400 100 300 80 200 60 100 40 0 20 0 -10 -9 -8 -7 -6 -5 -4 -3 -2 -1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Ambient temperature Operational hours Heat load% Capacity delivered by boiler Capacity delivered by ASHP Figure 4: Boiler and ASHP operating hours in bivalent parallel configuration Table 1: Example of bivalent changeover arrangement Building peak load 1,000kW Annual estimated operating cost of gas-only system 336,487 Capacity of heat pump 500kW Heat pump flow temp 55C Annual estimated operating cost of bivalent system 334,445 Gas boiler efficiency 85% Carbon emissions factor (gas) 0.21g/C02/kWh Carbon emissions factor (elec) Cost of difference - 2,042 Annual estimated carbon emissions of gas-only system 706,624 kg/C02 0.233g/C02/kWh Annual estimated carbon emissions of bivalent system 468,950 kg/C02 Cost/kWh gas 10p/kWh Carbon saved vs gas-only 34% Cost/kWh electricity 30p/kWh Heat share of heat pump 53% Table 2: Example of bivalent parallel arrangement Conclusion Building peak load 1,000kW 336,487 As the two examples show, introducing even a relatively small heat pump into an existing heating system will lead to carbon reductions, but applying that same heat pump capacity in different ways can achieve different outcomes. Choosing which configuration and capacity of bivalent system is best suited for a specific project depends on budget, existing infrastructure, desired outcome and, most importantly, how it is controlled. CJ Annual estimated operating cost of gas-only system Capacity of heat pump 500kW Heat pump flow temp *55C or 70C Annual estimated operating cost of bivalent system 409,787 Cost of difference +73,299 Annual estimated carbon emissions of gas-only system 706,624 kg/CO2 C HRIS NEWMAN is zero carbon design manager at Mitsubishi Electric 44 November 2023 www.cibsejournal.com Gas boiler efficiency 85% Carbon emissions factor (gas) 0.21g/C02/kWh Carbon emissions factor (elec) 0.233g/C02/kWh Annual estimated carbon emissions of bivalent system 359,324 kg/C02 Cost/kWh gas 10p/kWh Carbon saved vs gas-only 49% Cost/kWh electricity 30p/kWh Heat share of heat pump 91% *Change to higher flow temp at 50% load point Operational hours 500 Percentage of peak load This requires the heat pump to be capable of delivering the peak flow temperature of the system, allowing it to work side by side with the boiler at any time of the year. This means the heat pump can be sized to any capacity and, as Figure 4 shows, deliver heat energy on its own when it has the capacity, or in conjunction with the boiler when the load is greater than the heat pump capacity (the example shows a heat pump sized at 50% of peak load). Flow temperature can be fixed or weather-compensated, but the key design principle is that the heat pump is able to deliver the required flow temperature to meet peak heating demands via the existing heat emitters. This arrangement will deliver a large proportion of annual space heating load from the heat pump, and probably result in the lowest overall carbon emissions. However, operating the heat pump at potentially high flow temperatures and low ambient conditions will reduce its efficiency, so this configuration will probably result in an increased operational cost compared with the gas boiler-only system. Special consideration must also be given to the choice of heat pump, to ensure it delivers the necessary flow temperature and capacity in all operational conditions. A cascade arrangement or high-temperature natural refrigerant product may be needed to achieve the required flow temperature. The capacity of the heat pump can be freely selected to meet any site constraints of power supply or plant space, and consideration can be given to capital costs to achieve the optimum balance. To maximise the ratio of kWh contribution from the capacity of heat pump provided, our research shows the optimum capacity in relation to the building peak load is likely to be approximately 25-50%. See Table 2 for an example of a bivalent parallel arrangement. Calculations shown are for comparison purposes only 1